Flash evaporator and air conditioner including flash evaporator

A flash evaporator and port technology, applied in the field of fluid heat exchange, can solve the problems of no subcooling of liquid refrigerant and low overall energy efficiency ratio, and achieve the effect of improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

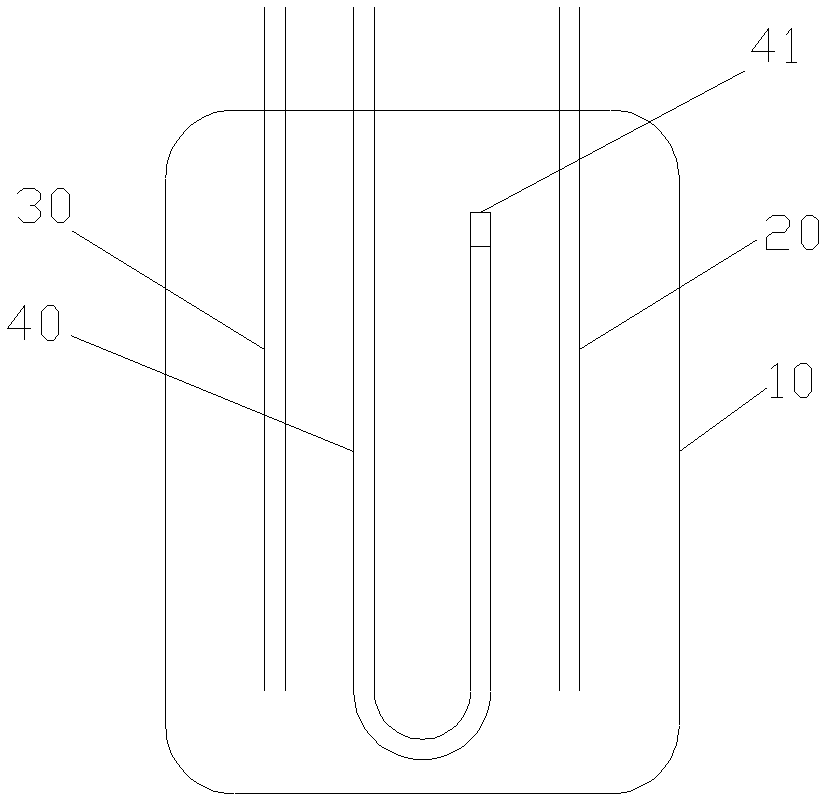

[0025] Such as figure 1 As shown, the flash evaporator of the present invention has a cylinder body 10, and the upper end of the cylinder body 10 is inserted into the cylinder body 10 respectively, and the lower end ports are respectively inserted into the liquid inlet pipe 30 and the liquid outlet pipe 20 in the cylinder body 10 and one end Located outside the cylinder block 10, the other end is located in the air outlet pipe 40 in the cylinder body, the lower end ports of the liquid inlet pipe 30 and the liquid outlet pipe 20 are inserted into the bottom of the cylinder block 10, and the air outlet pipe 40 has a cylinder with a position lower than the air outlet pipe 40. body internal port, and the position is lower than the lower pipe section of the lowest liquid level in the cylinder body 10, the lower pipe section is preferably a U-shaped pipe section or a V-shaped pipe section, and preferably, the bottom position of the lower pipe section is lower than the lower end port ...

Embodiment 2

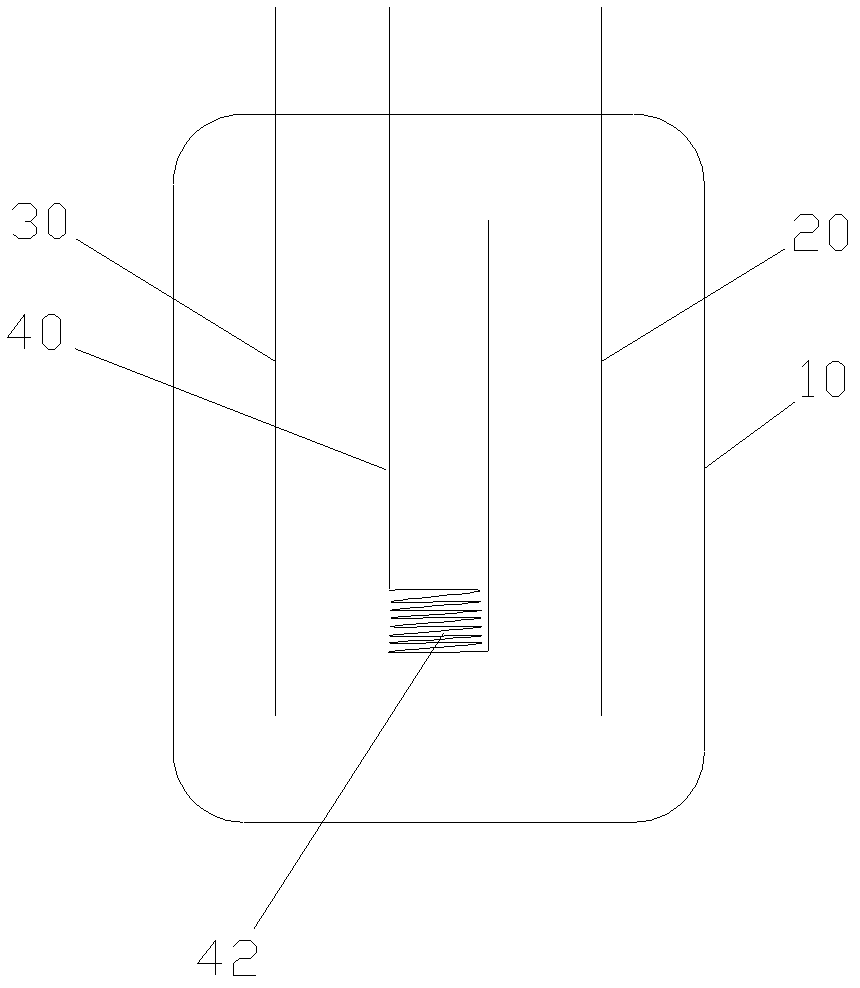

[0030] Such as image 3 As shown, the difference between the flash evaporator of the present invention and the structure in Embodiment 1 is that the length of the low-level pipe section is increased by setting the spirally wound pipe section 42 on the low-level pipe section. Preferably, the spirally wound pipe section 42 is located on the low-level pipe section , and communicate with the lower pipe section. And because the temperature of the lower layer of the liquid refrigerant in the cylinder 10 is lower than the temperature of the upper layer, the lower end of the coiled pipe section 42 is preferably connected to the inner port of the cylinder body of the gas outlet pipe 40 .

[0031] The flash evaporator of the present invention is provided with a coiled pipe section 42 on the outlet pipe 40, thereby increasing the length of the outlet pipe 40 soaked in the liquid refrigerant, which not only plays a throttling role, but also enhances the connection between the gaseous refr...

Embodiment 3

[0033] Such as Figure 4 As shown, the flash evaporator of the present invention is not only provided with a constriction 41 or a short capillary tube at the lower end port of the outlet pipe 40, but also provided with a coiled pipe section 42 at the bottom of the lower pipe section, so that the flash evaporator of the present invention The evaporator combines the advantages of the first embodiment and the second embodiment, better achieves the throttling effect and increases the energy efficiency ratio.

[0034] The constriction 41 or short capillary tube in the present invention, or the coiled pipe section 42 can also be arranged at other positions on the air outlet pipe 40, as long as the purpose of throttling can be achieved, and will not be repeated here.

[0035] In order to achieve a better throttling effect, the air outlet pipe 40 in the present invention is preferably a copper pipe, especially a copper pipe with a small diameter.

[0036] The present invention also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com