Diagonal bracing for supporting side plate of crossbeam of building

A technology of supporting boards and beams, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of time-consuming and labor-intensive, wood loss, etc., and achieve the effects of protecting forest resources, saving wood, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

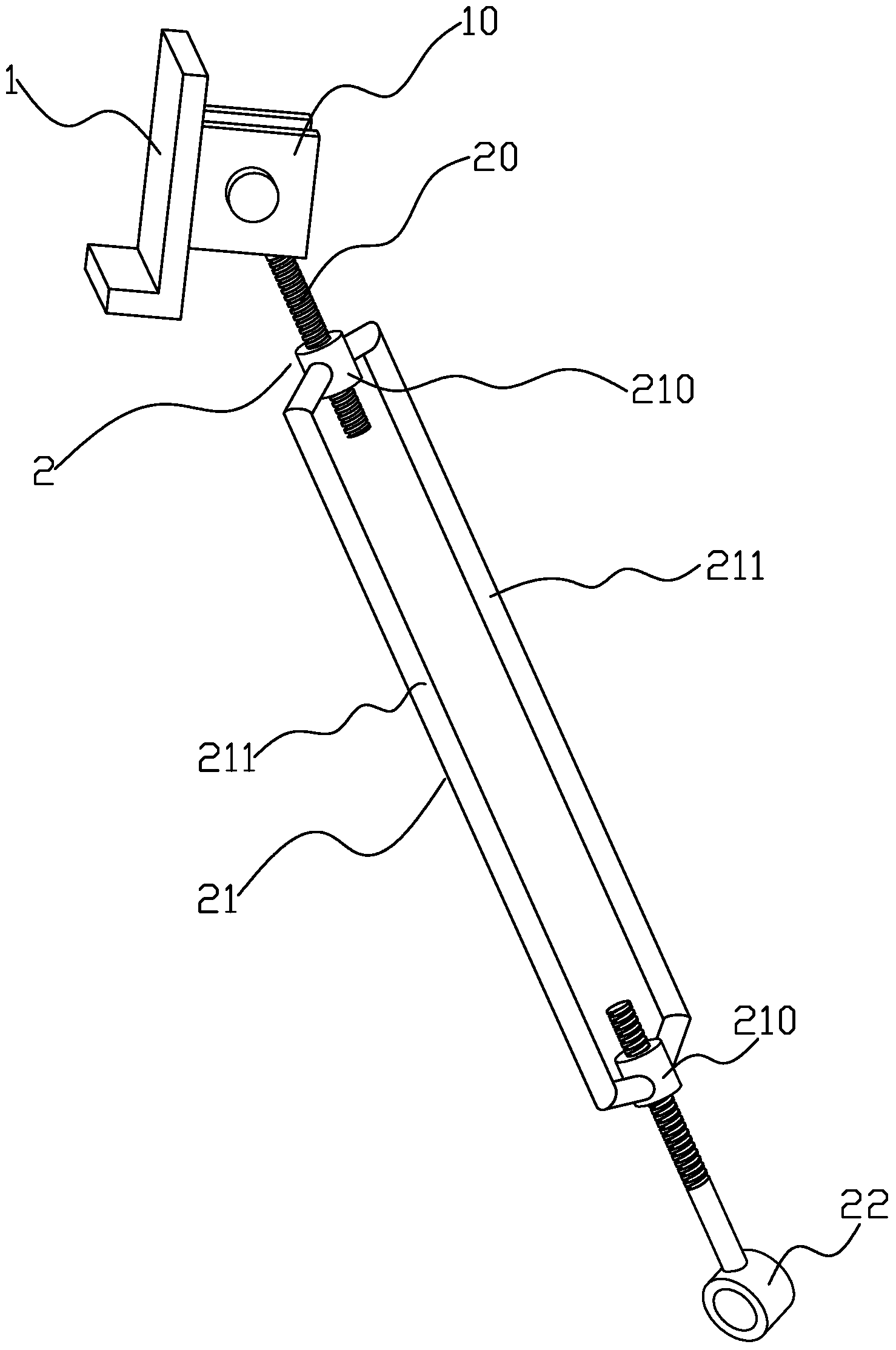

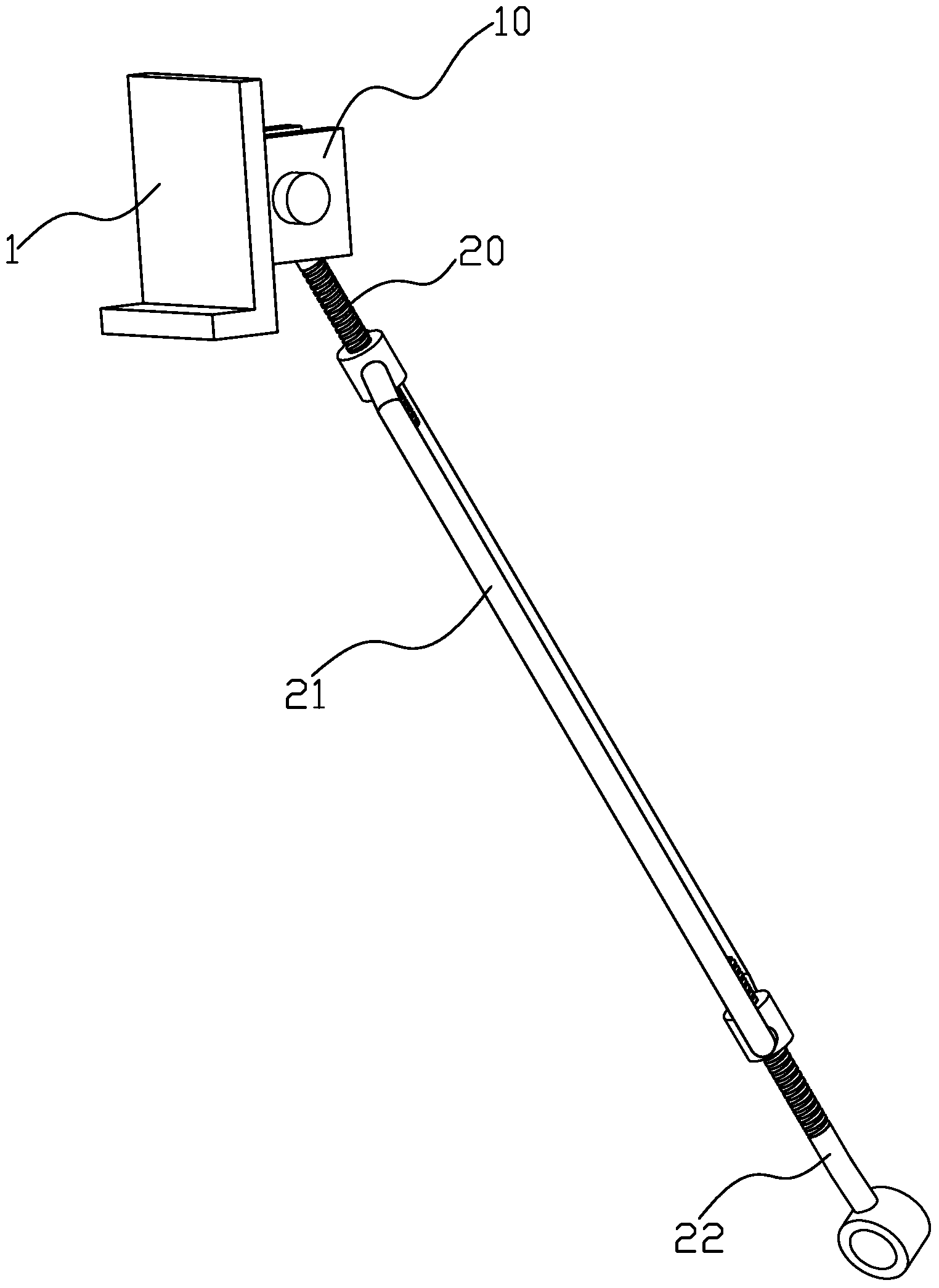

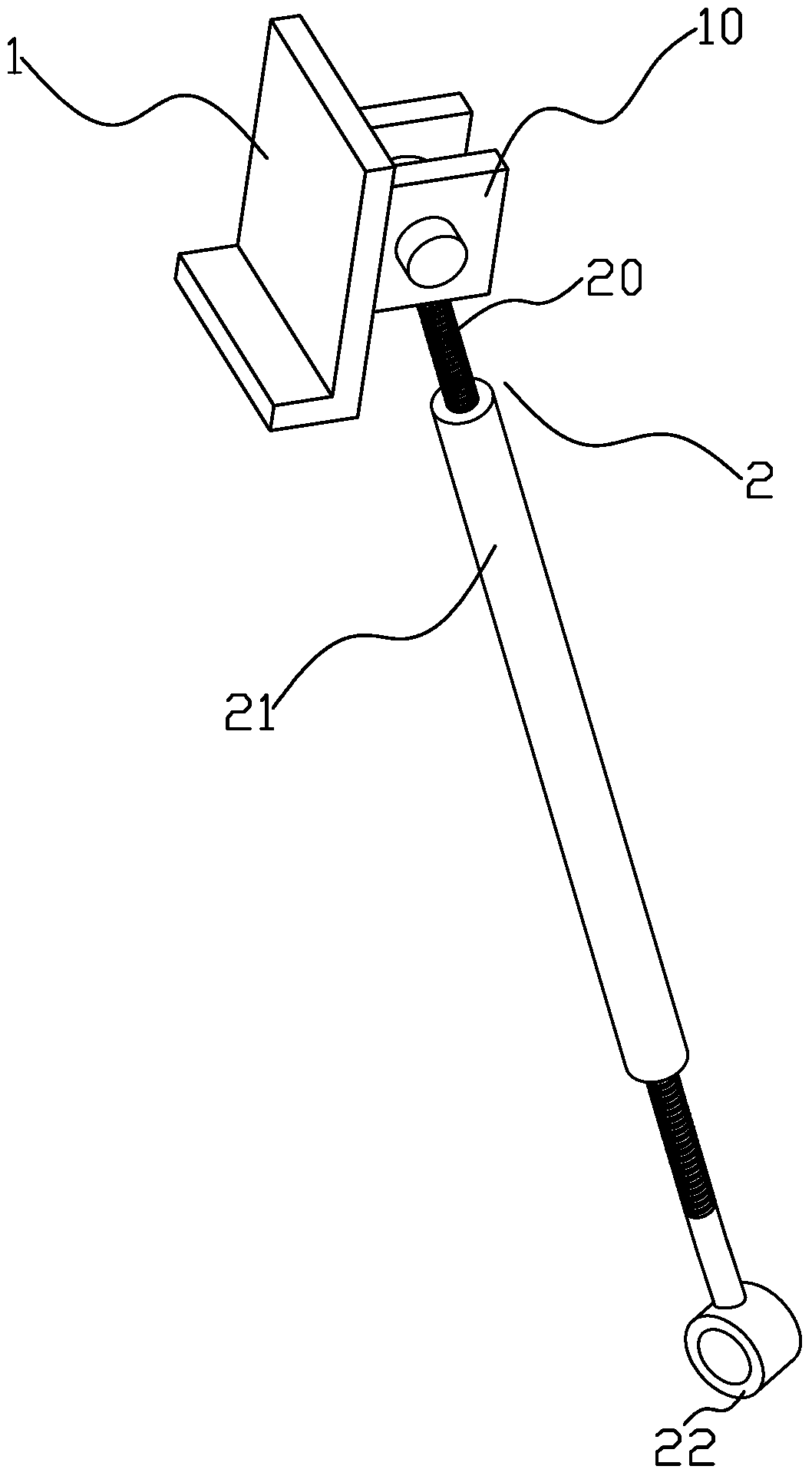

[0015] refer to figure 1 As shown in Figure 3, a brace for supporting the side panels of building beams, including a support plate 1 for abutting against the side panels of building beams, in the present invention, the support plate 1 is preferably made of metal materials It is an L-shaped flat plate. The vertical part of the flat plate can abut against the side of the auxiliary square timber that presses the side plate of the building beam, and its horizontal part can support the bottom of the auxiliary square timber, so that the auxiliary square timber can be pressed tightly on the On the positions of different heights of the side plates of the building beams, the side of the support plate 1 away from the side plates of the building beams is provided with a hinged seat 10, the hinged seat 10 is hinged with a telescopic rod 2 through a pin shaft, and the other end of the telescopic rod 2 It can be fixedly abutted with other parts.

[0016] Further, as a preferred embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com