Method for predicting dwell time for strain-strengthening austenitic stainless steel low temperature container

A technology of austenitic stainless steel and low temperature container, which is applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems such as the uncertainty of the holding pressure process time and the influence of the strain hardening process time on the product production cycle, and achieves technical feasibility, Simple operation and accurate prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Taking the domestic typical austenitic stainless steel S30408 material as an example, the main process of the prediction method of strain-strengthening holding pressure time for low-temperature vessels made of austenitic stainless steel based on the normal temperature creep theory is further described:

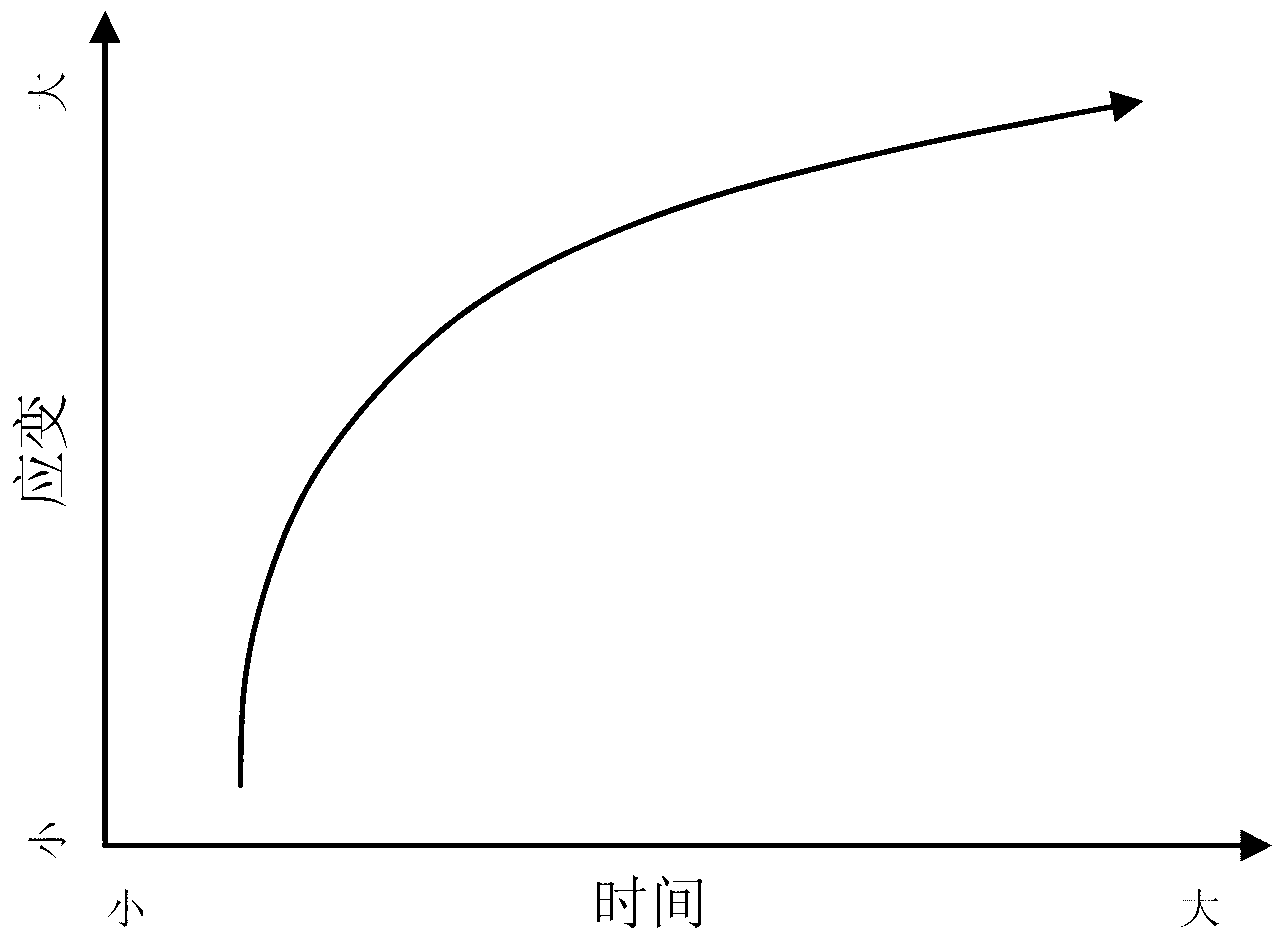

[0024] (1) Through the material test, the stress-dependent curve of the normal-temperature creep of austenitic stainless steel for cryogenic vessels is established.

[0025] Take the austenitic stainless steel to be processed, and carry out the tensile test at room temperature according to the standard GB / T 228.1. The test process is controlled by force. After stretching the sample at the same rate to the set stress, the pressure is maintained until the strain change becomes stable, and relevant data are collected. The value range of the set stress σ should be within the material yield strength (Rp 0.2 ) and the enhanced pressure of the container;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com