Technology for separating and purifying 2,4-diaminotoluene and 2,6-diaminotoluene by derivatization crystallization process

A technology of diaminotoluene and crystallization, which is applied in the purification/separation of amino compounds, organic chemistry and other directions, can solve the problems of low recovery rate, large waste of raw materials, serious environmental pollution, etc., and achieves low production cost, convenient operation and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

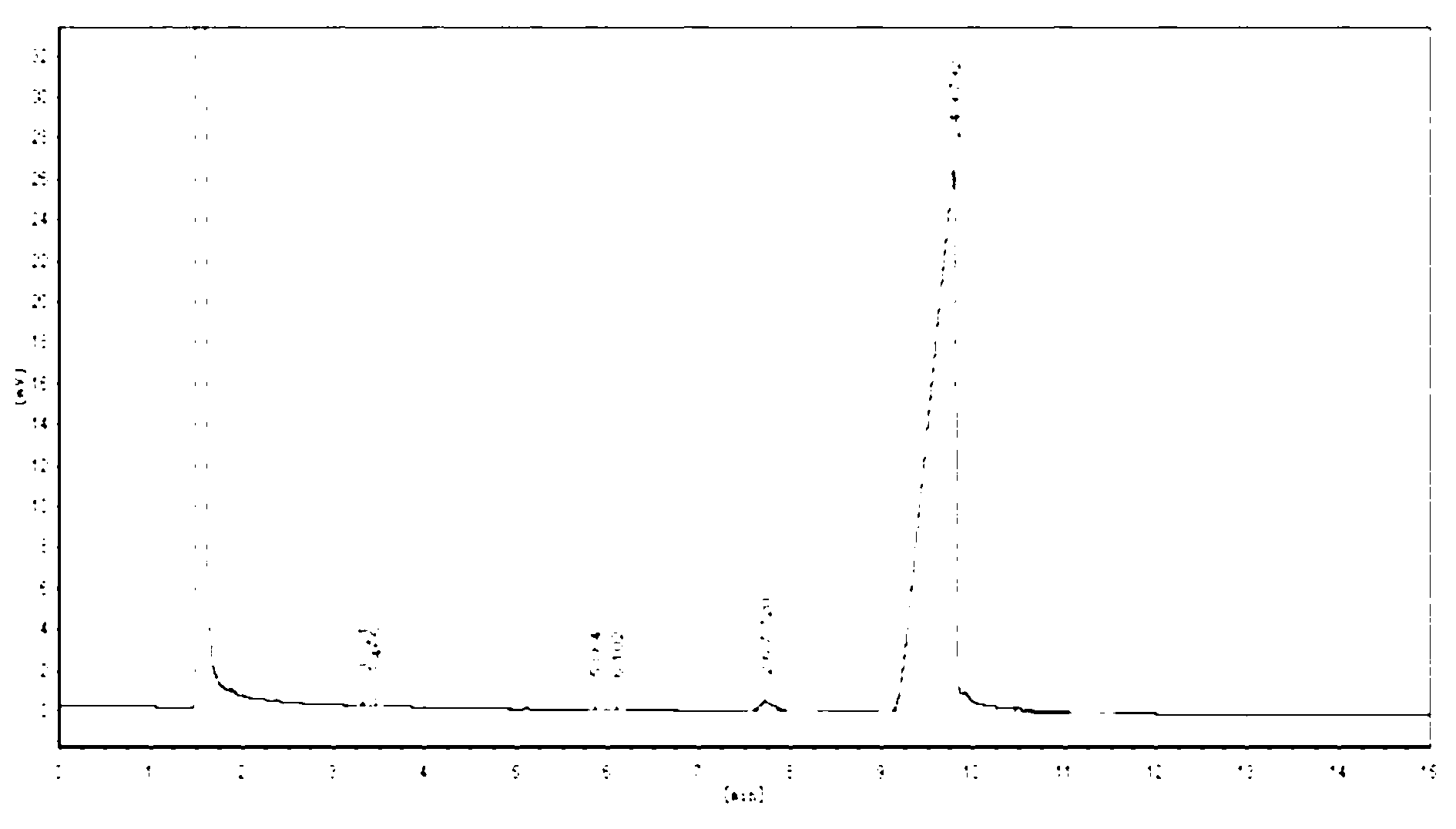

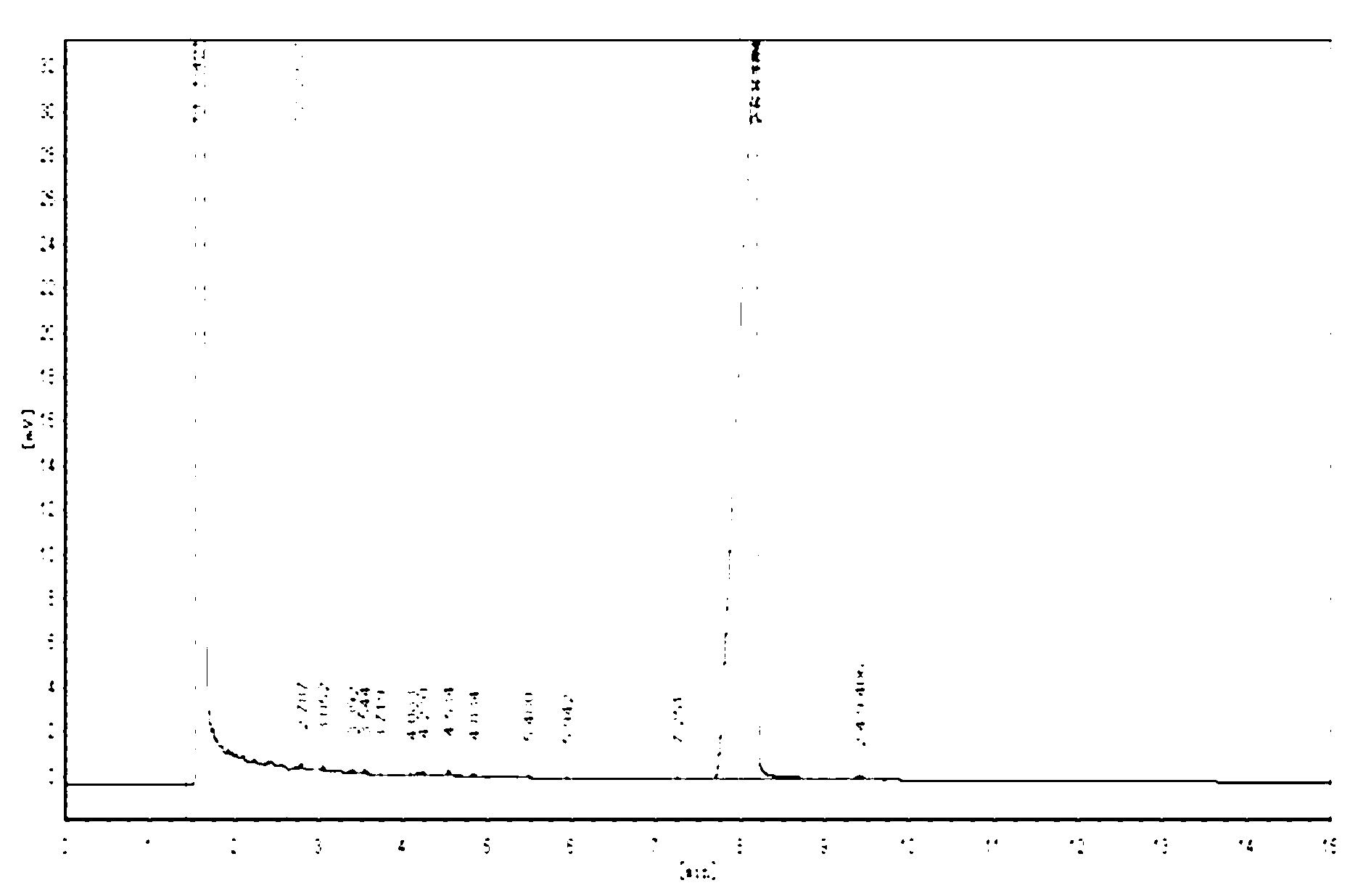

Image

Examples

Embodiment Construction

[0015] (1) Rectification of TDA raw materials to remove tar, water, solvent and other impurities

[0016] Using diaminotoluene TDA (a mixture of 80% 2,4-diaminotoluene and 20% 2,6-diaminotoluene) purchased on the market as raw material, the TDA raw material is first crushed, put into a rectifying tower and separated Segment rectification treatment to separate impurities such as moisture, tar and solvents in different amounts contained in the raw material to obtain TDA raw material with a certain purity.

[0017] (2) Crystallization separation and secondary purification of 2,6-diaminotoluene

[0018] Put the raw material TDA after rectification and degumming treatment into distilled water (the mass ratio of solid to liquid is 1:15~1:20), add hydrochloric acid to adjust the pH=6~6.5, and then add sodium chloride with a dosage of 3~5% of raw material TDA , heated to 95~97°C, stirring the catalytic reaction for 0.5~1 hour under the condition of keeping the temperature consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com