Numerical control modeling flower-carving machine for vertical type art pottery

A technology of artistic ceramics and engraving machines, which is applied in decorative art, digital control, processing models, etc., can solve the problems of long time-consuming, difficult processing, and a lot of manual labor, so as to improve modeling efficiency, improve labor efficiency, Design scientific and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

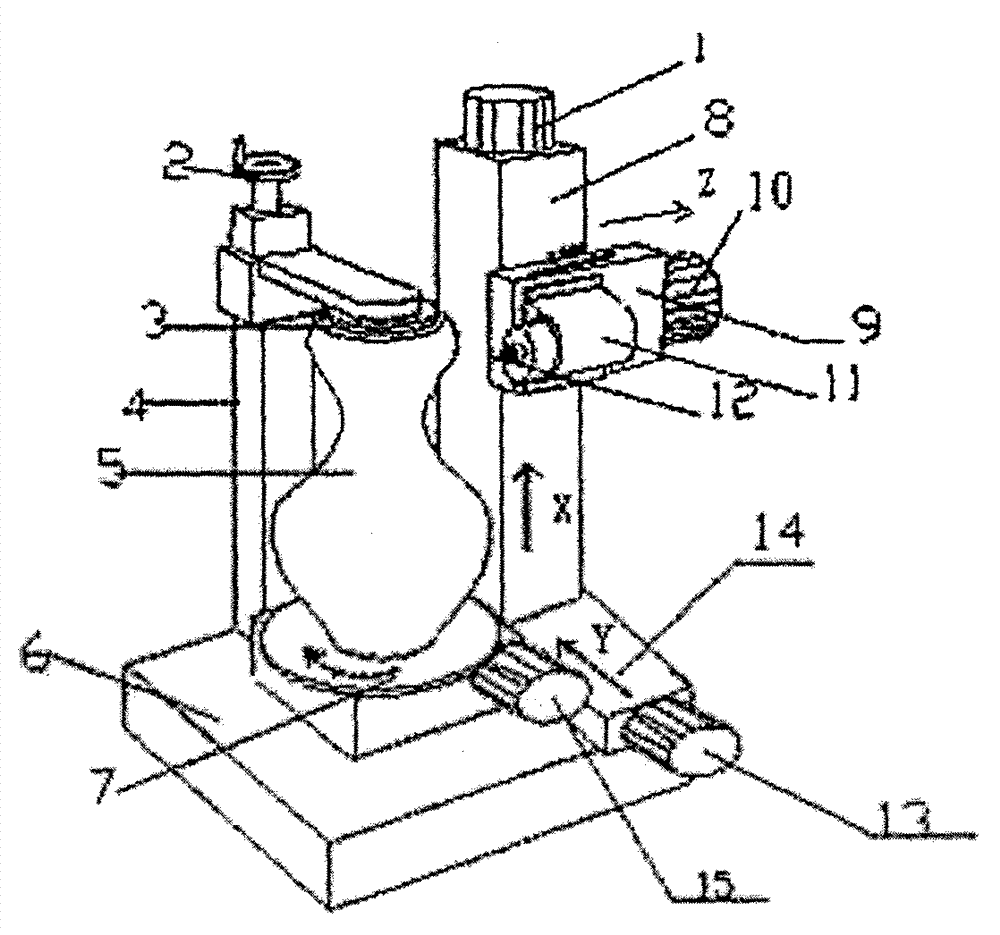

[0025] Combine below figure 1 , the present invention is further described:

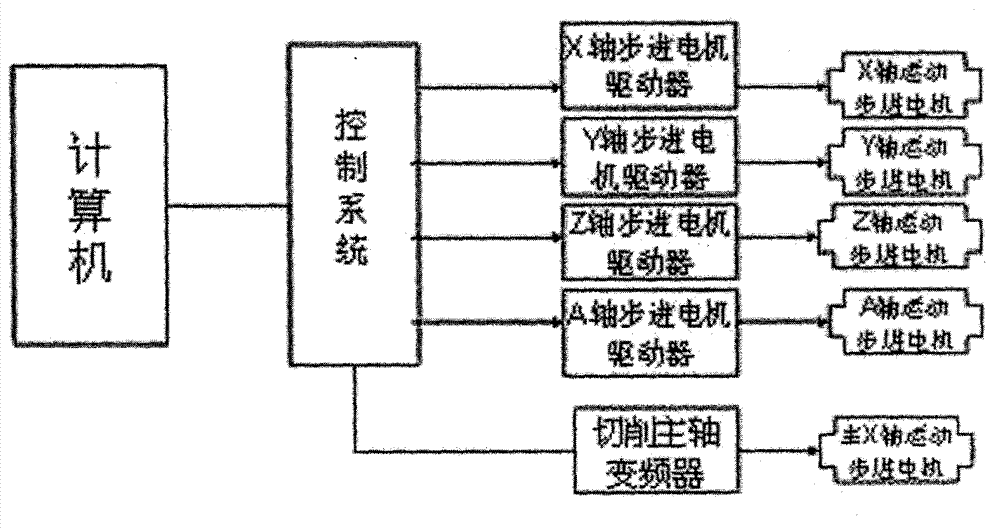

[0026] Such as figure 1 As shown, the present invention discloses a vertical numerical control modeling engraving machine for artistic ceramics, which is composed of a computer system, a controller and a host computer, and the controller is arranged between the computer and the host computer. The main engine includes machine base 6, workpiece mounting device, X-axis working system, Y-axis working system and Z-axis working system. Both the workpiece mounting device and the Y-axis working system are set on In the system, the Z-axis working system is set on the X-axis working system. On the Z-axis working system, a main shaft motor 11 is also arranged, and an engraving knife 12 is arranged at one end of the main shaft motor 11 shaft, and the engraving knife 12 and the main shaft motor 11 are interlocked. The main shaft motor 11 rotates at a high speed under the drive of the frequency converter, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com