Carriage covering composite material with silkworm cocoon-imitating winded and braided structure and preparation method thereof

A composite material and silkworm cocoon technology, which is applied to the carriage skin and its manufacture, and the composite material carriage skin and its manufacture field, can solve the problems of the skin being prone to bubbling, affecting the speed increase, brittle fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] A composite material compartment skin imitating silkworm cocoon winding and weaving structure. 0.025 meters.

[0101] The composite car body skin of the imitation silkworm cocoon winding and braiding structure according to the present invention is characterized in that it is prepared according to the following steps:

[0102] 1) Preparation of non-metal material mandrel;

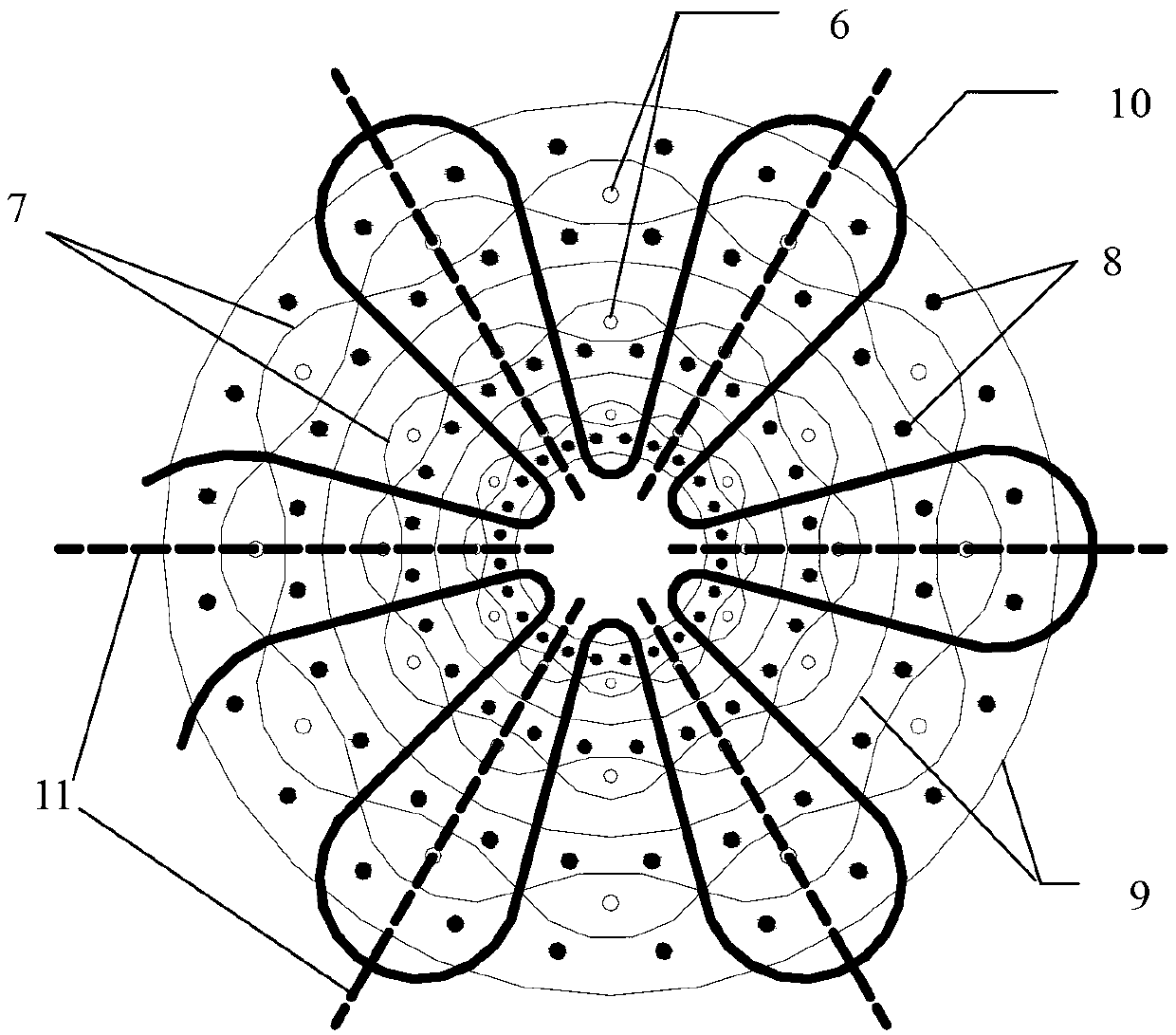

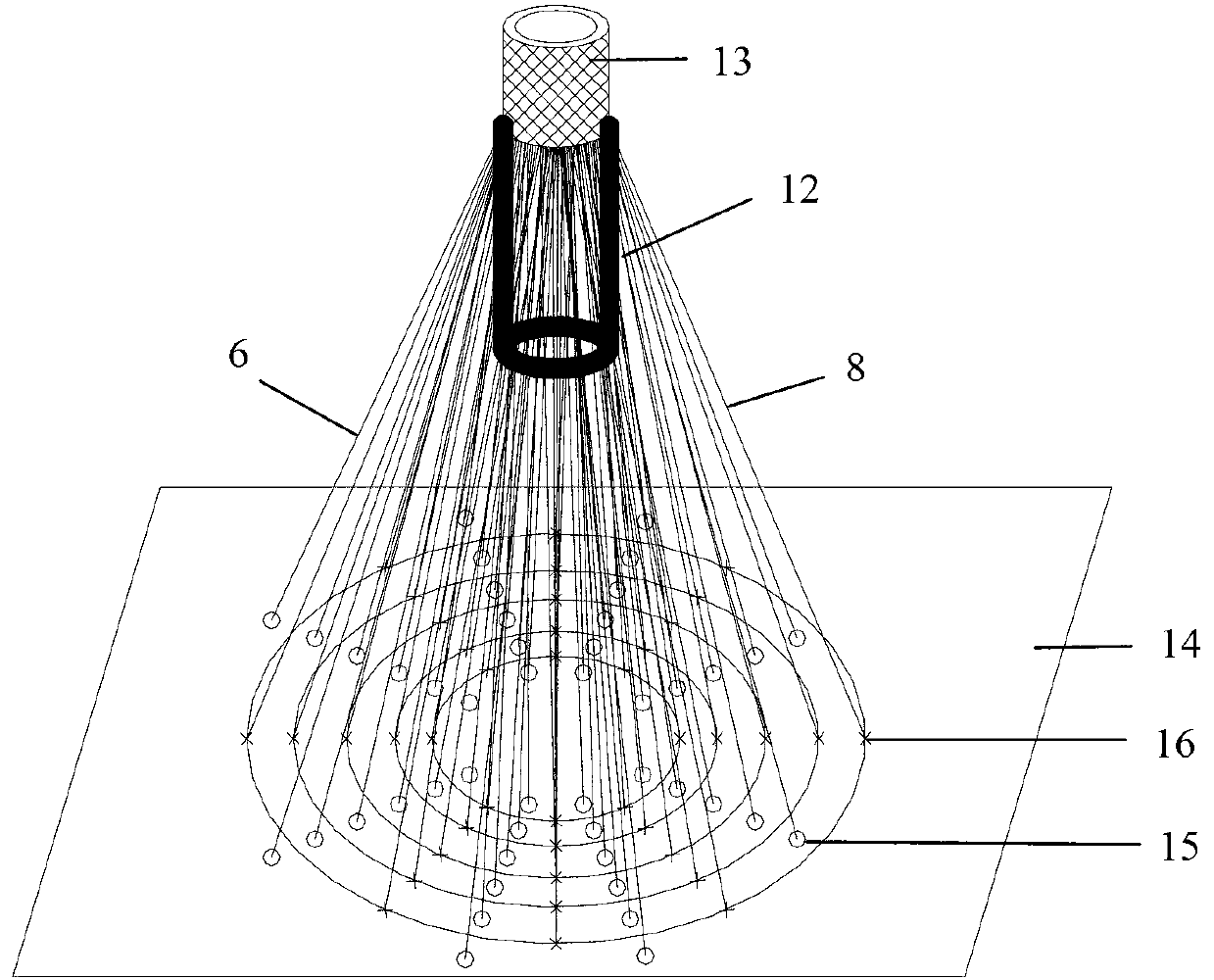

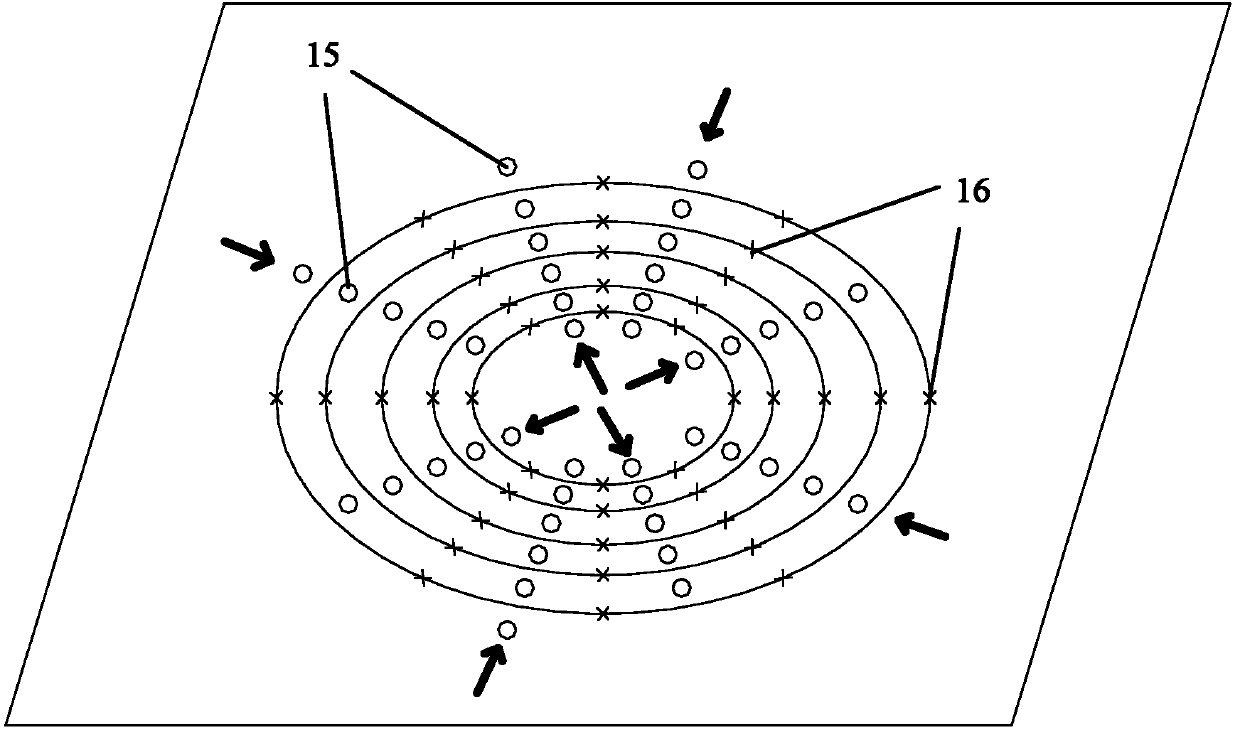

[0103] Figure 4 It is a schematic diagram of the winding and weaving method of the composite material of the imitation silkworm cocoon winding and weaving structure of the present invention. Firstly, design and prepare non-metal material mandrel 12, use wooden material as raw material, design and manufacture composite material inner mandrel, the outer shape of mandrel is ring with circular chamfer. The outer dimensions of the mandrel are the same as those of the inner surface of the prepared composite material car skin. In this embodiment, the external dimensions of the annular mandrel are 30 met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com