Active pay-off device for knitting machine

A technology of a pay-off device and a braiding machine, which is applied in the field of active pay-off devices for braiding machines, and can solve problems affecting the uniformity and compactness of the wire arrangement of the pay-off reel, the inability to install the pay-off reel, and the labor intensity of workers. Achieve the effects of wide application range, saving operation time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

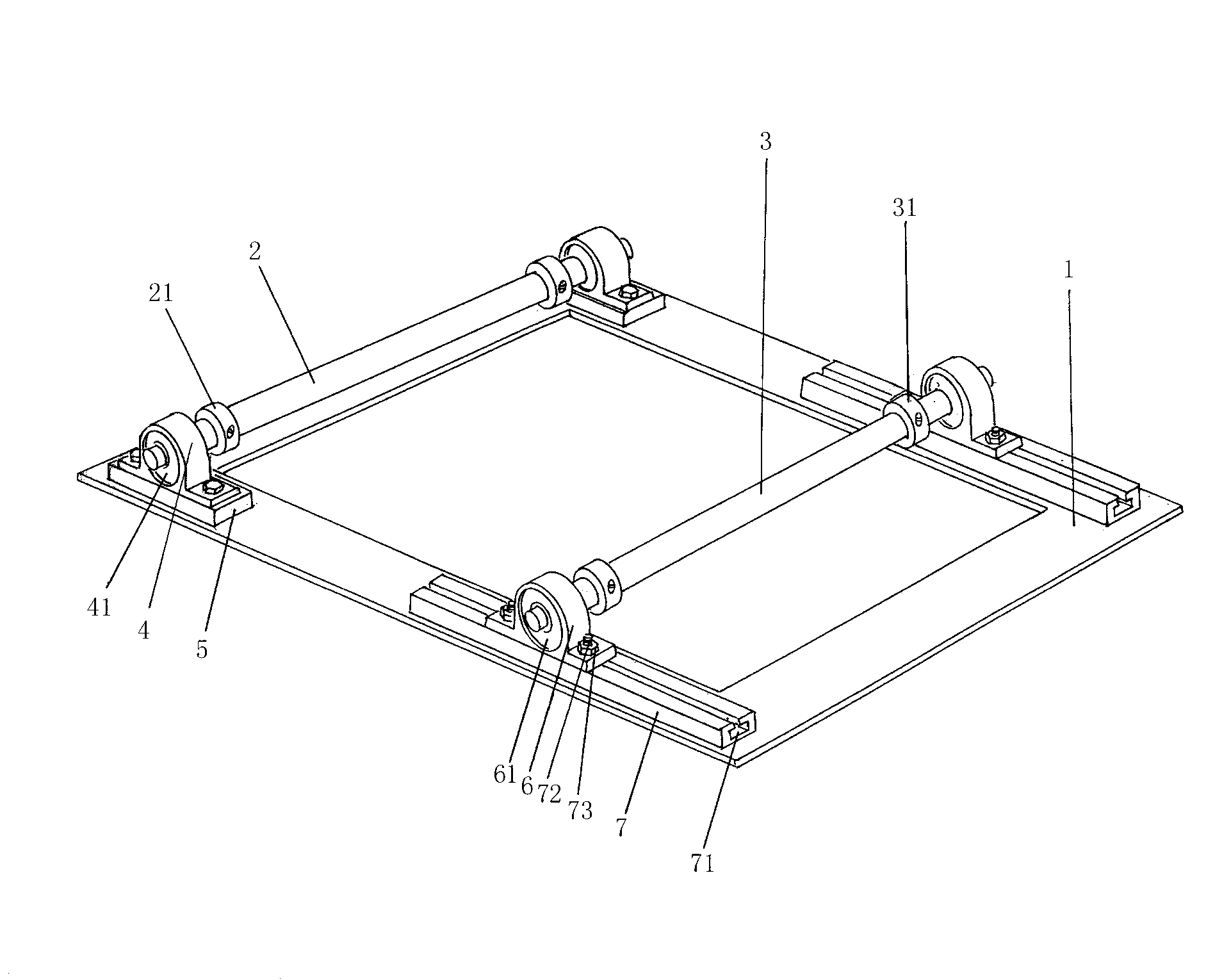

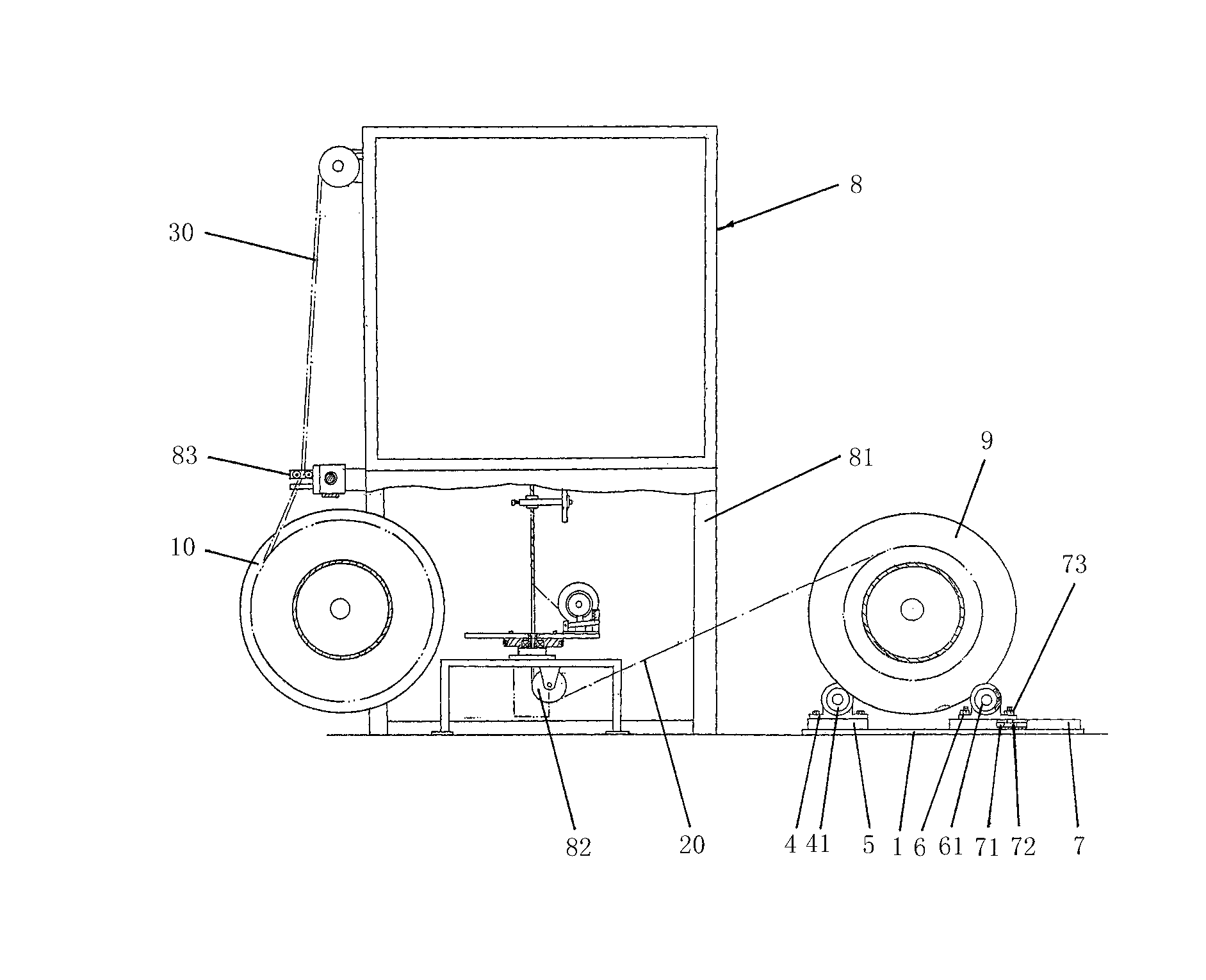

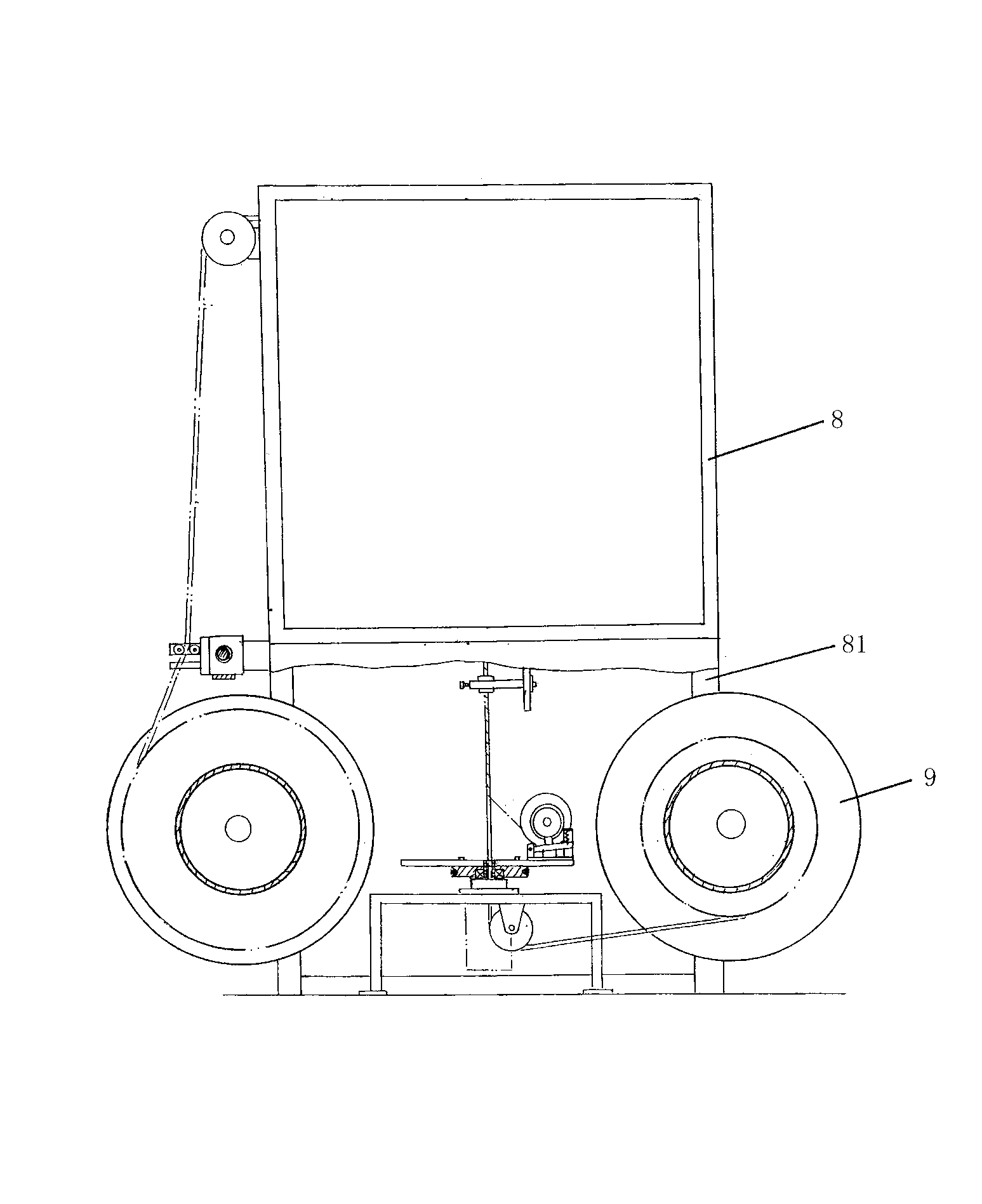

[0019] see figure 1 and combine figure 2 , the present invention is an active pay-off device for a braiding machine, the braiding machine includes a braiding machine body 8, and the active pay-off device includes a base 1, a front roller shaft 2, a rear roller shaft 3, and a pair of front bearing seats 4 and a pair of rear bearing seats 6, the base 1 is installed on the floor in front of the knitting machine body 8 in the use state, and the pair of front bearing seats 4 is installed on the base 1 and is close to the knitting machine body 8 is provided on one side, and a front rolling bearing 41 is respectively rotatably installed in a pair of front bearing seats 4, and both ends of the front roller shaft 2 are installed on the front rolling bearings 41 in a pair of front bearing seats 4. The pair of rear bearing seats 6 are installed on the base 1 and are arranged on the side away from the main body 8 of the knitting machine, and rear rolling bearings 61 are respectively ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com