Heat storage-heat supply system and its application in hydroponics

A heat supply system and hydroponic technology, applied in cultivation, application, soilless cultivation, etc., can solve the problem of inability to store heat in summer, and achieve the effects of small heat loss, easy heat dissipation, and large heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The location of the project facility in this embodiment is the low-carbon agriculture and forestry practice base of Shanghai Jiaotong University (Lianmin Village, Pujiang Town).

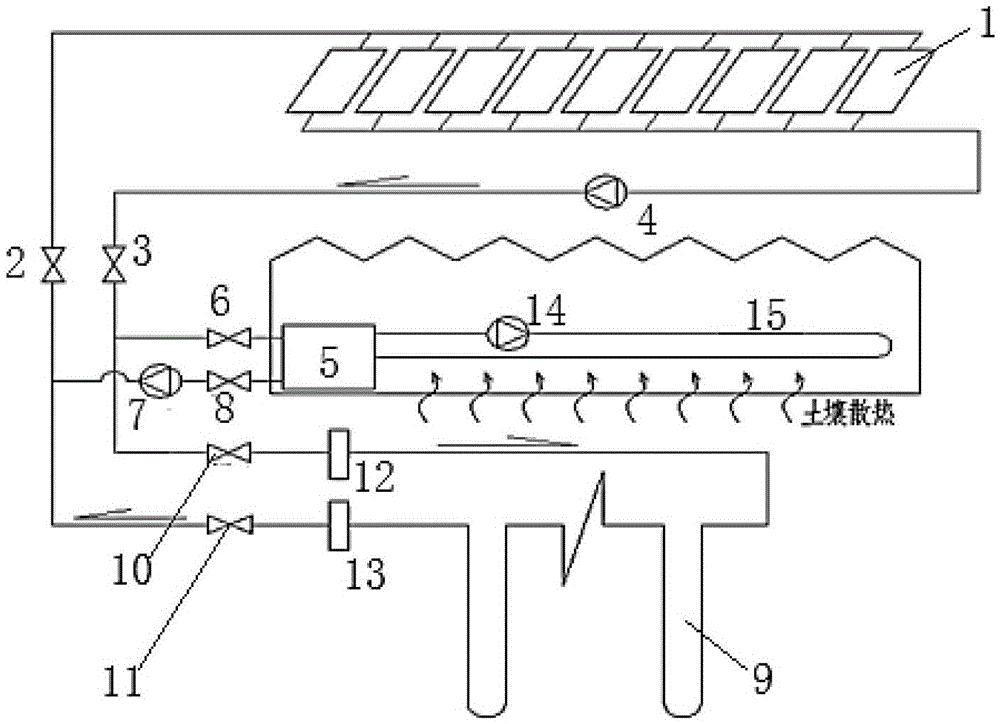

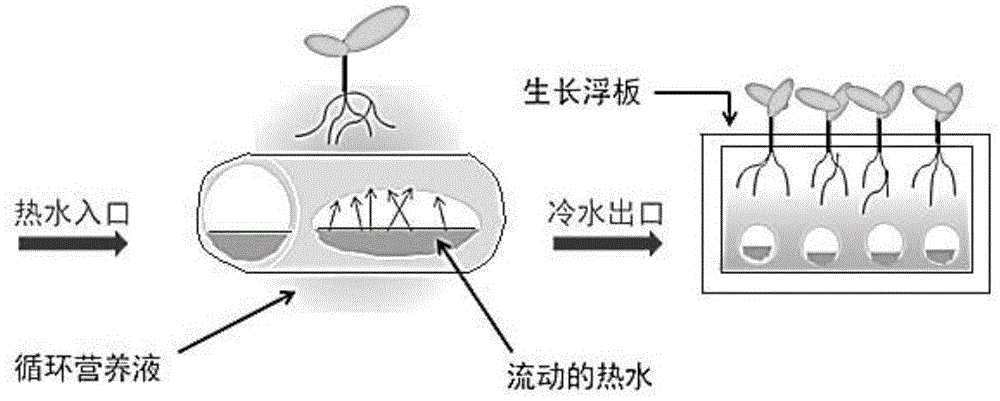

[0036] Such as figure 1 As shown, the cultivation device of this embodiment includes: a heat collecting device, a thermal storage body buried in the ground, an above-ground heating system and a thermal insulation water tank 5 arranged in the greenhouse, wherein: the water inlet and the water outlet of the thermal storage body are respectively connected to the The water outlet end of the heat collecting device is connected with the water inlet end, and the hot water of the heat collecting device circulates to the heat storage body to realize heat storage; the first water inlet end of the thermal insulation water tank 5 is connected with the water outlet end of the heat collecting device, and the second inlet The water end is connected to the water outlet of the heat storage body, and the therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com