Components for modular automation

An automation device, modular technology, applied in the direction of logic controller, electrical components, support structure installation for automation/industrial process control, etc., can solve the problem of inaccurate measurement results of SMD sensors, inability to accurately detect incoming air temperature, Issues affecting SMD sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

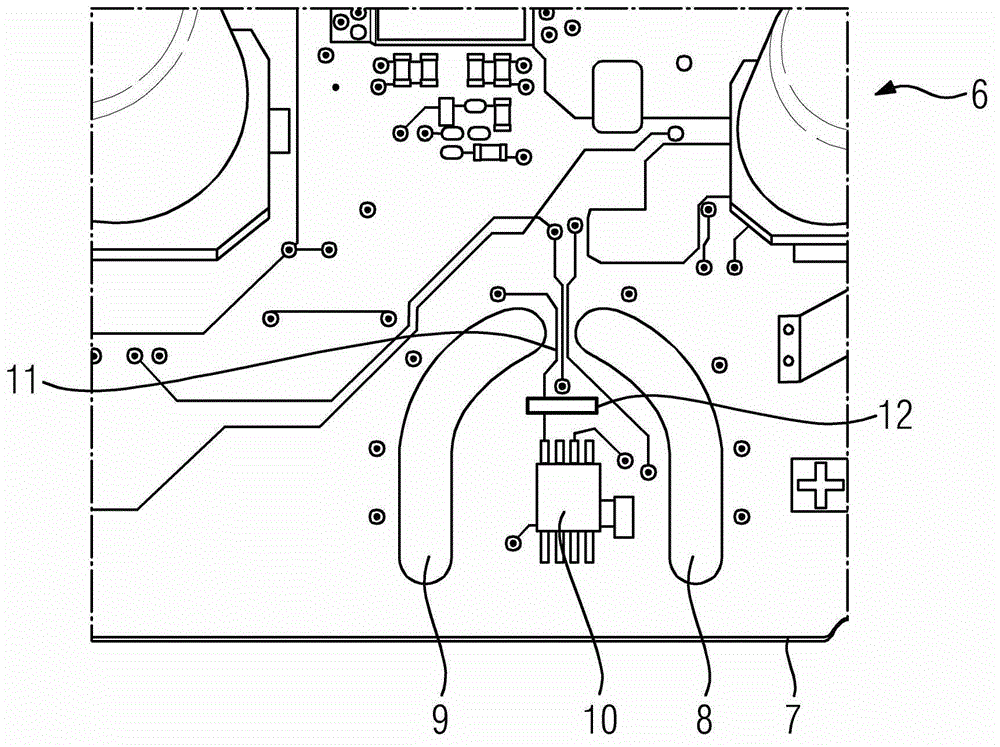

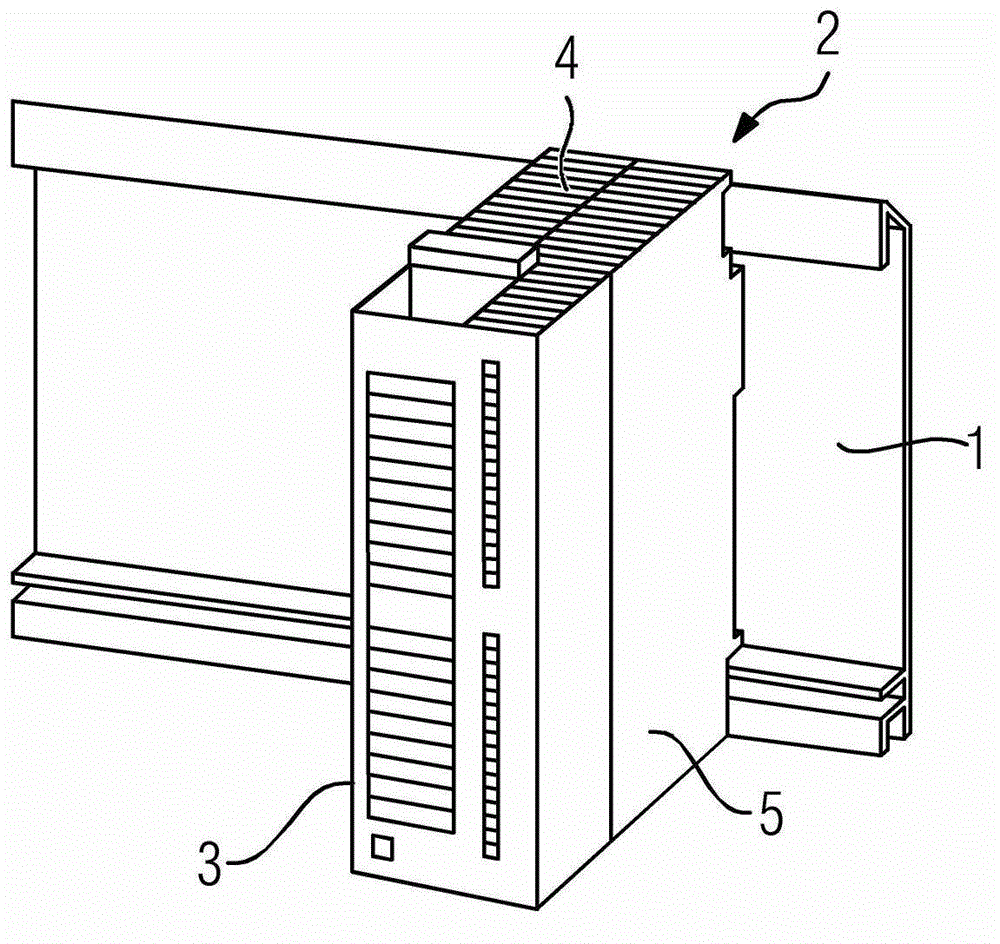

[0010] first reference figure 2 , which shows a known assembly 2 arranged on a carrier 1 . Heat removal is effected essentially by convection in such a way that the incoming air flows through the openings (air intakes) on the underside of the housing enclosure 3 through the electrical and electronic components of the assembly and finally through the housing enclosure The opening 4 (air outlet) on the top surface of 2, wherein the air flowing through the housing encapsulation cover 2 takes away the heat of the components arranged or assembled on the SMD circuit board. The SMD circuit board is positioned or arranged in the housing encapsulation 3 parallel to the side wall 5 of the housing encapsulation 3 and has an SMD sensor for detecting the temperature of the incoming air.

[0011] In order to prevent the heat source arranged on the circuit board from causing inaccurate measurement results of the SMD sensor, the SMD sensor is arranged between the first and second gaps of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com