Series direct-current motor four-switch topological device and control method thereof

A series-excited motor and four-switch technology, applied in the direction of electronic commutation motor control, control system, stop device, etc., can solve the problems of loose mechanical connection between terminals and devices, faulty terminals, and large mechanical adhesion of cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

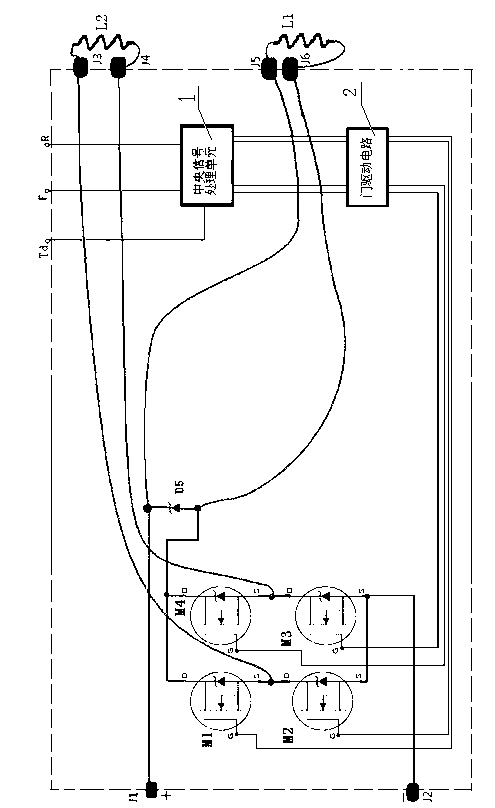

[0020] Such as figure 1 As shown, the control device for realizing the electronic commutation of the series-excited motor is provided with a full-bridge circuit composed of four semiconductor switching elements M1, M2, M3 and M4, a central signal processing unit 1, a gate drive circuit 2, a continuous flow diode D5. The common end of the two lower arms M2 and M3 of the full-bridge circuit is connected to the negative terminal J2 of the DC bus, the winding L2 of the series-wound motor is connected between the two output ends of the full-bridge circuit, and the winding L1 of the series-wound motor is connected to the DC Between the positive terminal J1 of the bus and the common terminals of the two upper arms M1 and M4 of the full bridge circuit, the cathode of the freewheeling diode D5 is connected to the positive terminal J1 of the DC bus, and the anode of the freewheeling diode D5 is connected to the two upper arms of the full bridge circuit The common terminal of M1 and M4 ...

Embodiment 2

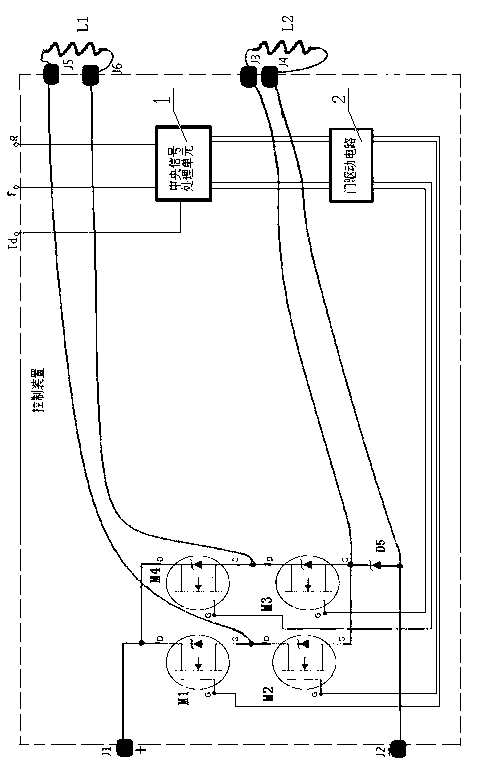

[0034] Such as figure 2 As shown, the control device for realizing the electronic commutation of the series-excited motor is equipped with a full-bridge circuit composed of semiconductor switching elements M1, M2, M3 and M4, a central signal processing unit 1, a gate drive circuit 2, and a freewheeling diode D5.

[0035] The common ends of the two upper arms M1 and M4 of the full-bridge circuit are connected to the positive terminal J1 of the DC bus, the winding L1 of the series-wound motor is connected between the two output ends of the full-bridge circuit, and the winding L2 of the series-wound motor is connected to the DC bus Between the negative terminal J2 and the common terminals of the two lower arms M2 and M3 of the full bridge circuit, the anode of the freewheeling diode D5 is connected to the negative terminal J2 of the DC bus, and the cathode of the freewheeling diode D5 is connected to the two lower arms of the full bridge circuit. The common end of the arms M2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com