Non-contact electric energy transmission system for vertical drilling system

An electric energy transmission system and vertical drilling technology, which is applied in natural gas drilling and petroleum fields, can solve the problem of not considering the influence of system resonant frequency, not taking into account the downhole high temperature, high pressure, strong vibration shock, small structural space and mud erosion, Unable to use automatic vertical drilling tools and other problems to achieve the effect of simplifying hardware circuits and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

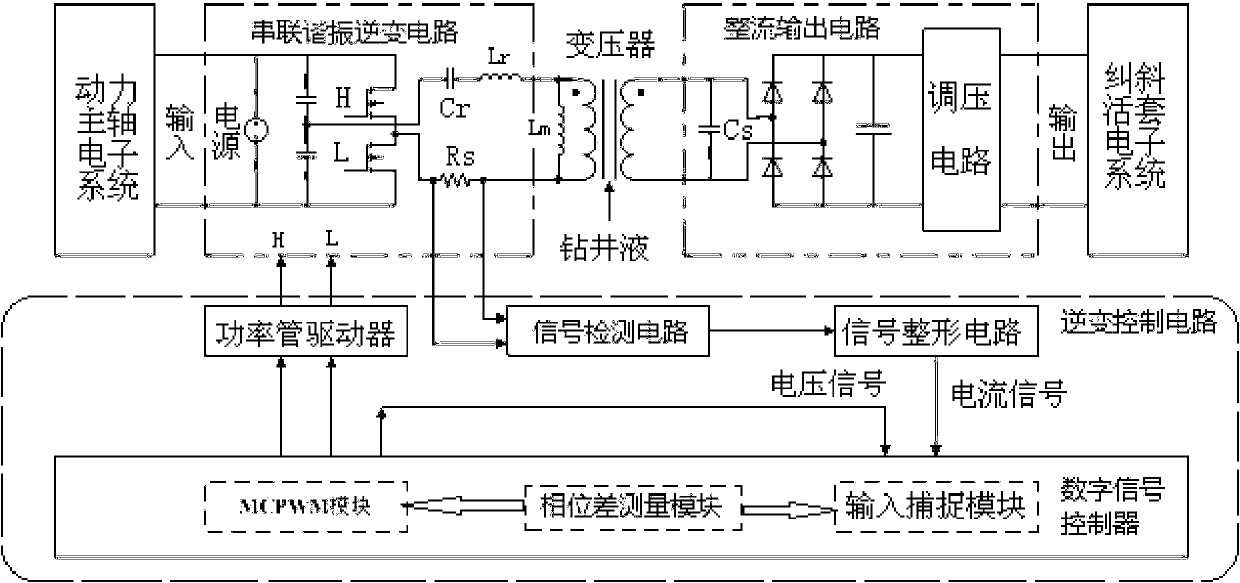

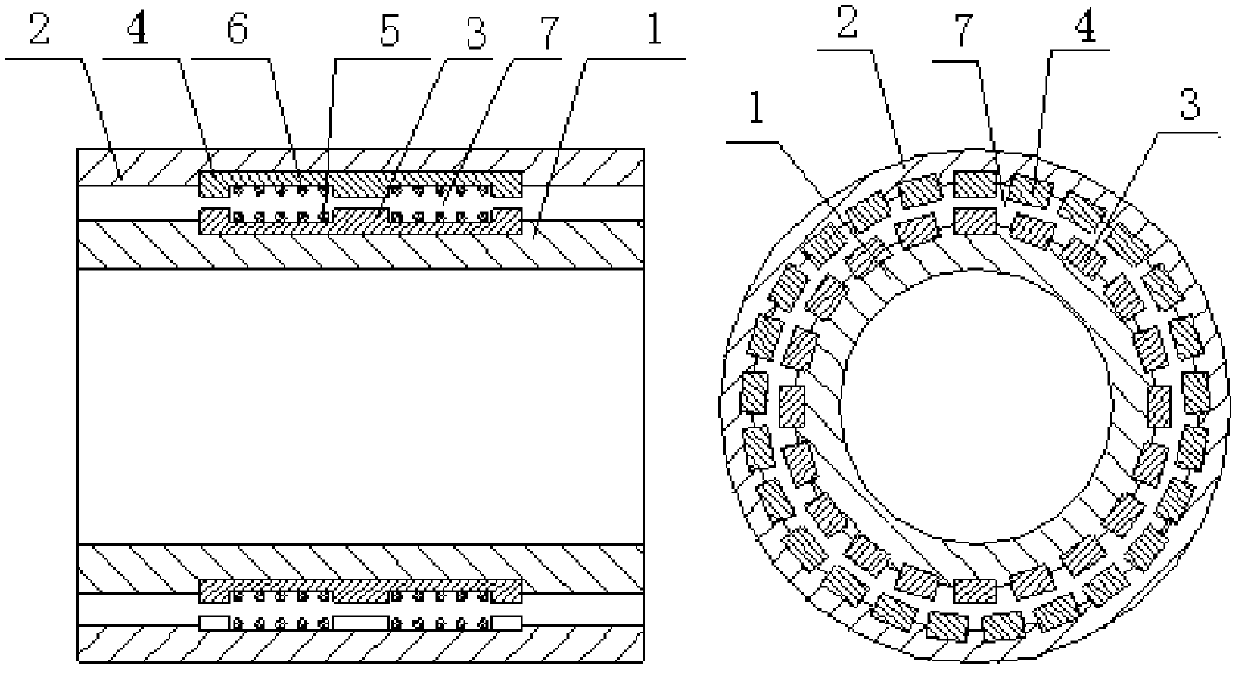

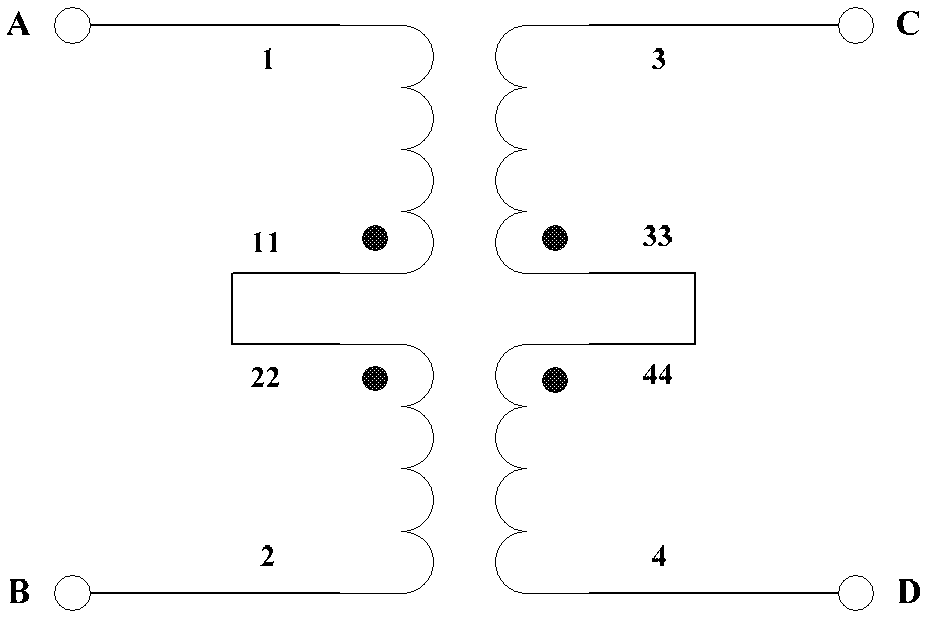

[0054] see figure 1 and figure 2 As shown, the present invention provides a non-contact power transmission system for a vertical drilling system, including: a transformer for realizing power transmission;

[0055] a series resonant inverter circuit connected to the primary winding of the transformer;

[0056] The rectification output circuit is respectively connected with the secondary winding of the transformer and the rectification electric control system of the drilling system, and is used to rectify the current output by the secondary winding and send it to the rectification electric control system;

[0057] An inverter control circuit, connected to the series resonant inverter circuit, for controlling the output voltage and cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com