Scanning electrochemical microscope experimental device for tests in various environments

A technology of scanning electrochemistry and experimental equipment, which is applied in the field of scanning electrochemical microscope experimental equipment, can solve the problem of inability to scan electrochemical test research kinetic research, the probe cannot move back and forth, left and right, up and down, and cannot reflect the real shape of the working electrode. Appearance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

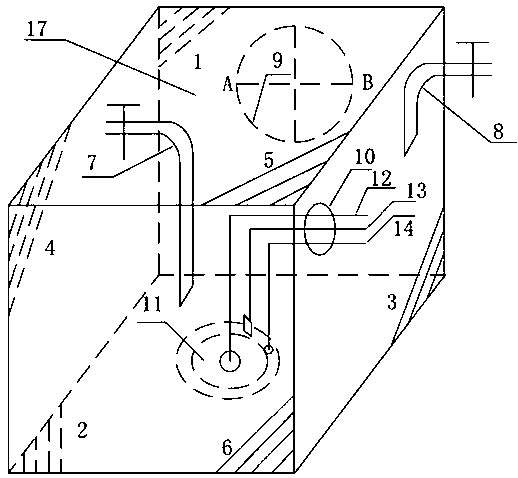

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

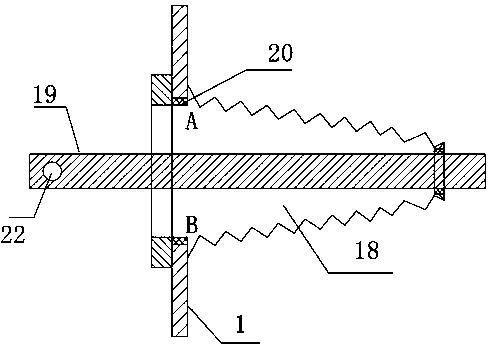

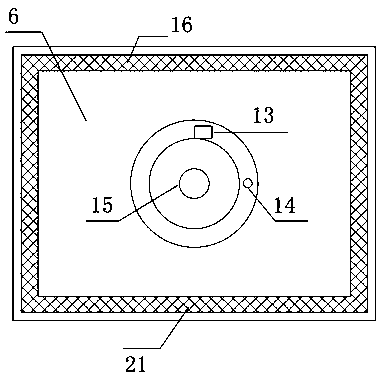

[0013] Referring to the accompanying drawings, the present invention includes: a square glass cover 17 (without upper and lower bottom surfaces), an air intake pipe 7, an exhaust pipe 8, a carrier plate 6 with an electrolytic cell tank 11, a glass cover cover plate 5, a probe 12, Reference electrode 13, counter electrode 14, plastic cone 18, probe holder 19, circular rubber sealing ring 20, square rubber sealing ring 21. Wherein the top of the plastic cone 18 and the probe holder 19 are fixed as a whole with an adhesive, and the probe 12 is placed in the probe hole 22 of the probe holder 19; the square glass cover 17 is a whole formed by casting, including Front, rear, left and right 4 identical side panels; the middle and upper part of the rear side panel 1 has a round hole 9 matching the bottom end of the plastic cone 18 in size, and the bottom end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com