Laser optical electric axis power measuring probe

A technology for measuring probe and shaft power, applied in power metering, measuring device, torque metering and other directions, it can solve the problems affected by complex environmental factors, difficult installation and maintenance of strain gauges, unsatisfactory measurement results, etc., to improve maintainability. performance, convenient operation and maintenance, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

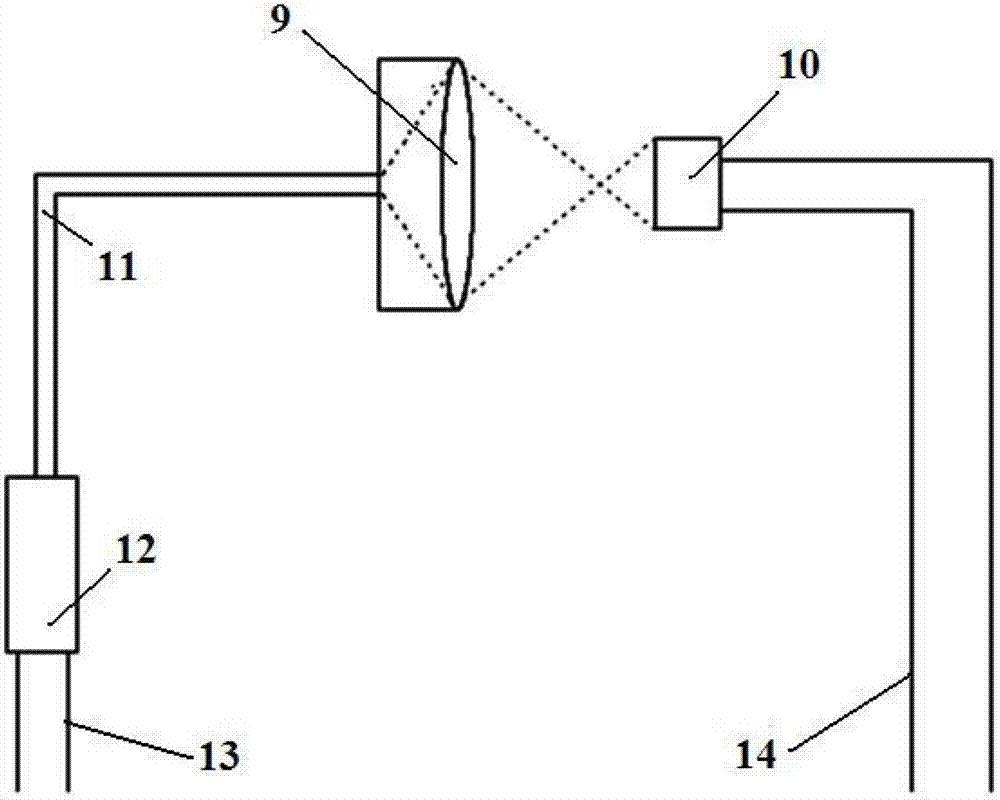

[0028] The laser photoelectric axial power measurement probe of the present invention adopts the structure of optical fiber + laser diode + optical fiber focusing mirror + photoelectric detector, and integrates all components into the inside of the sensor probe, no longer needs to use optical fiber outside the probe, and only uses a short The distance is fixed to the optical fiber, and the external cable is connected to the power supply and the electrical signal to the controller through a waterproof aviation plug. The entire probe shell is designed to be waterproof and dustproof to meet the use requirements in harsh environments.

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the content of the present invention is not limited.

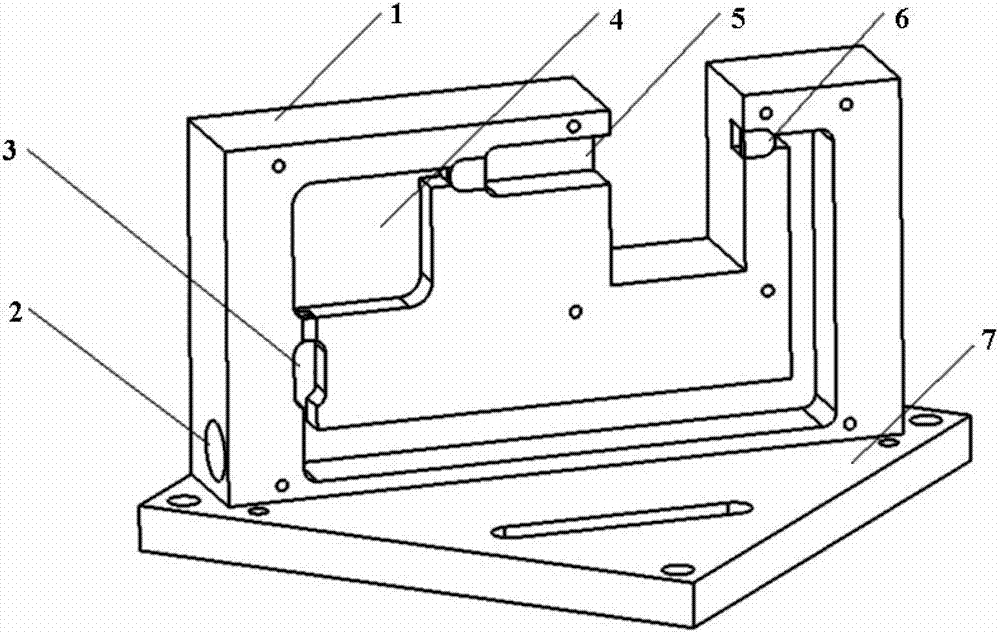

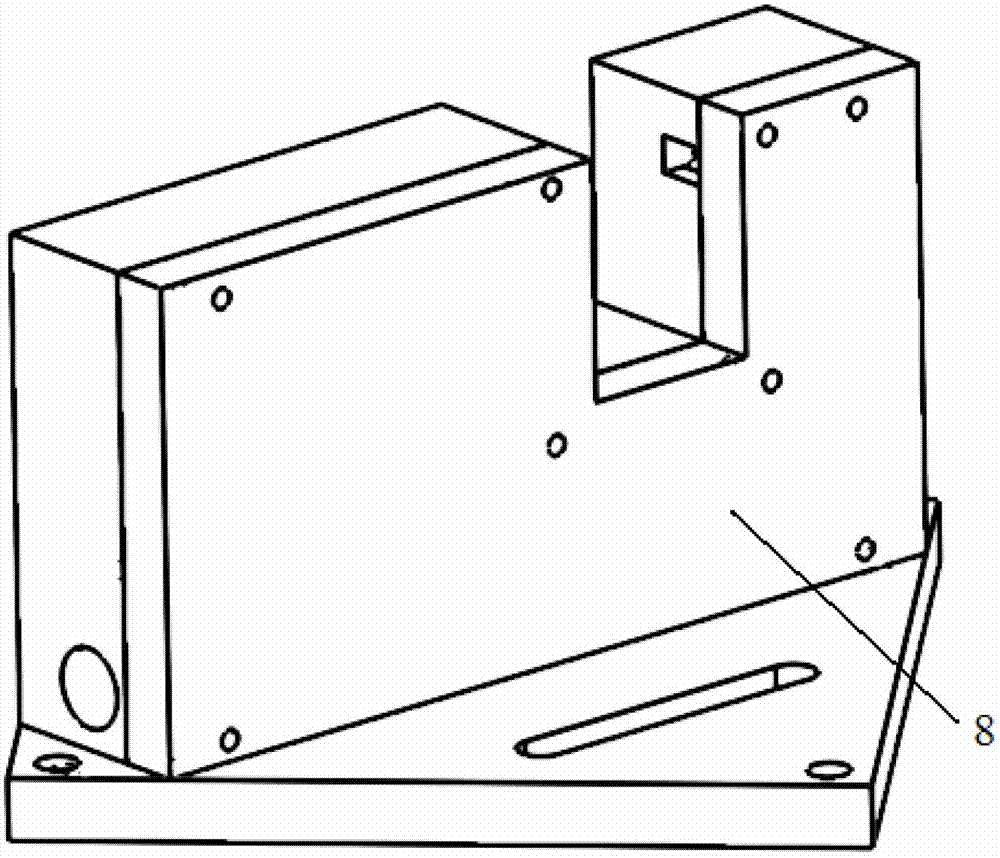

[0030] The laser photoelectric shaft power measurement probe applied to the non-contact photoelectric shaft power measurement device provided by the present invention h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com