Transverse tube-type cooling tower with leakage testing and overhauling function and overhauling and leakage testing method

A cooling tower and tube-type technology, which is applied in the field of leak test and repair devices for horizontal tube cooling towers, can solve the problems of affecting the stable operation of production, time-consuming and laborious, and difficult maintenance, etc., and achieves novel structure, wide application value, and small investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

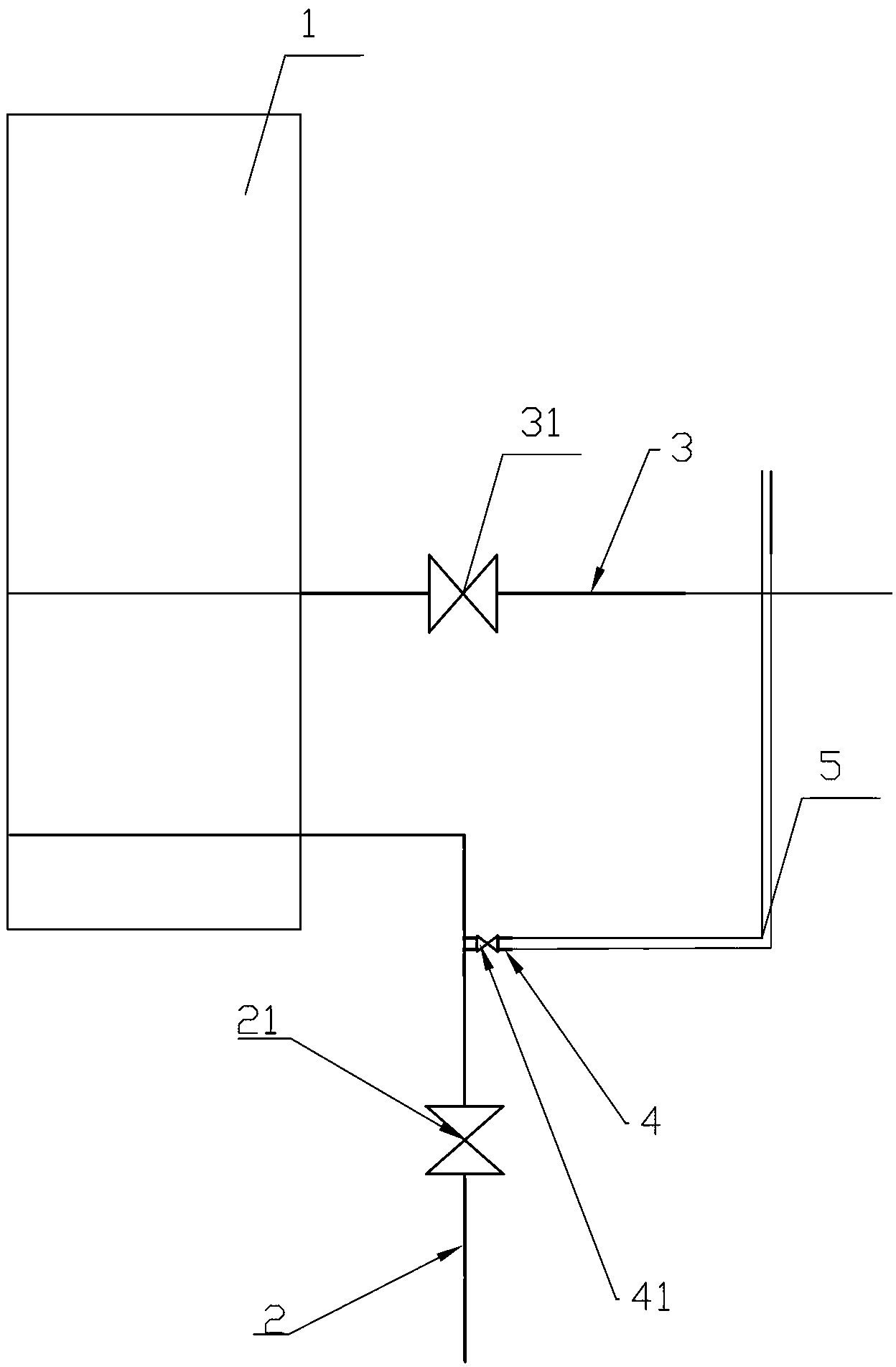

[0019] Such as figure 1 As shown, the present invention is a horizontal tube cooling tower with leak test and repair function, which includes a cooling tower body 1, and the cooling tower body 1 is correspondingly provided with a low-temperature water inlet pipe 2 and a low-temperature water outlet pipe 3. The low-temperature water inlet pipe 2 and the low-temperature water outlet pipe 3 are correspondingly provided with a low-temperature water inlet valve 21 and a low-temperature water outlet valve 31, and the low-temperature water inlet valve 21 and the cooling tower body 1 are provided on the low-temperature water inlet pipe The cooling water inlet is short-connected 4, and the cooling water inlet short-connect 4 is connected to a transparent rubber tube 5.

[0020] The cooling water inlet short-connector 4 is provided with an on-off valve 41, which is designed to close the on-off valve when the horizontal-tube cooling tower is not overhauled and tested for leaks, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com