Fixing structure of led light bar socket

A technology of LED light bar and fixed structure, which is applied in the direction of light source fixing, lighting device parts, lighting device, etc. Assembly efficiency, reducing the number of wire harnesses, and simplifying the effect of connection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

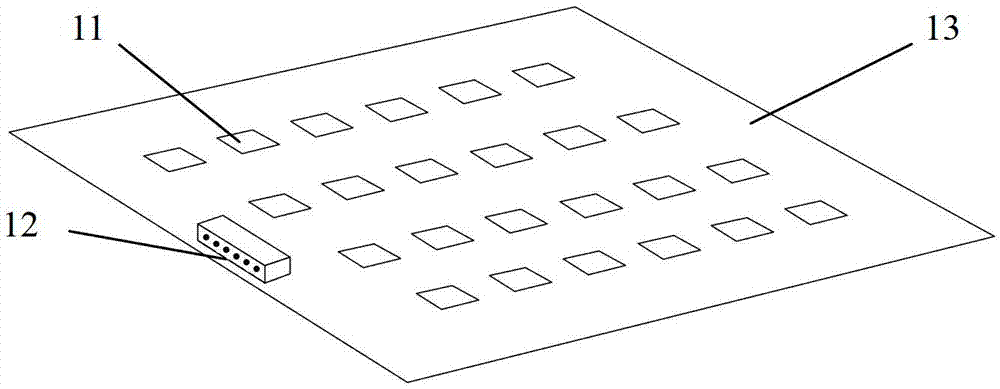

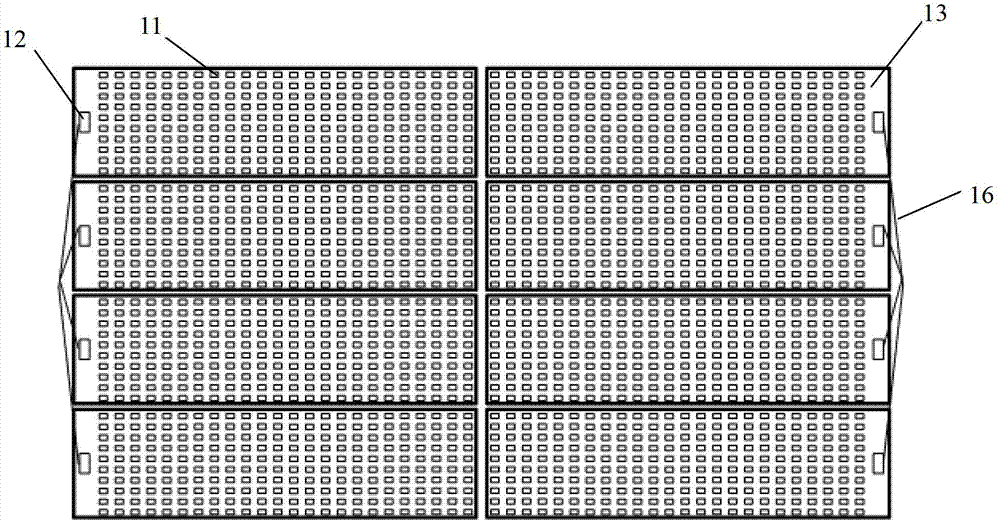

Embodiment 1

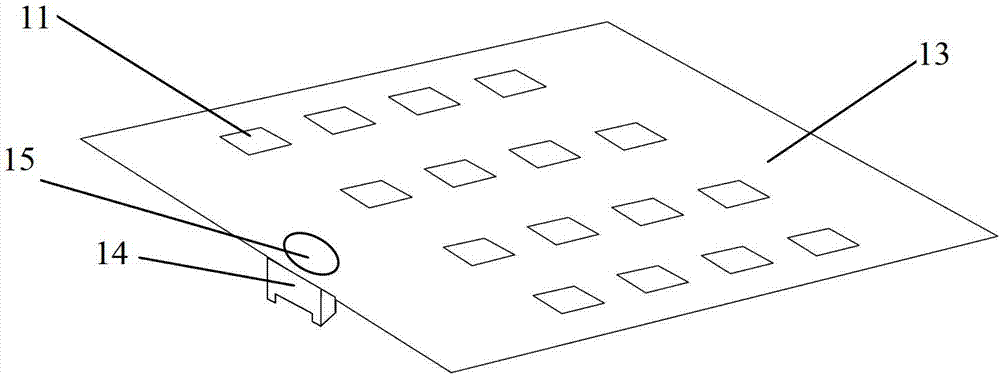

[0025] Such as Figure 4 Shown is a schematic cross-sectional view of the plug-in type LED light bar socket 14 of this example. In this embodiment, the LED light bar socket 14 is reversely welded on the PCB board 13 by hand or special equipment to strengthen its connection with the PCB board 13. connection reliability. On the PCB board 13, there is a small hole 15 at the position corresponding to the LED light bar socket 14. After the LED light 11 is fixed, the LED light 11 can be connected to the LED light bar socket 14 with a wire from the outside of the backboard, and the LED light can also be connected. Bar socket 14 is connected with external power supply through aperture 15. It can be seen from the figure that the LED light bar socket 14 includes a connecting piece 141 on the front side of the PCB 13 and a connecting piece 142 on the back side of the PCB 13 . In practical applications, the LED light can be connected to the socket through the small hole 15 and the conne...

Embodiment 2

[0029] Such as Figure 5 , in this embodiment, the LED light bar socket 14 is reversely mounted on the PCB board 13 through a placement machine or a tooling fixture, and the LED light bar socket 14 and the LED light 11 are respectively fixed on both sides of the PCB board 13. Through this structure There is no need to consider wiring harness connections when installing LED strips. The connection between the LED light strip socket 14 and the external power supply board is realized through the part of the LED light strip socket 14 on the back of the PCB 13 , and the connection with the light strip is realized through the connecting piece 141 on the front of the PCB 13 . After the light bar and internal parts are assembled, the light bar wiring harness can be directly connected to the light bar and power supply on the back of the module when the whole machine is assembled, which simplifies the connection of the light bar to the wiring harness interface on the back of the module a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com