Low-noise hydraulic design method of centrifugal pump with low specific speed

A hydraulic design and design method technology, applied to pumps, calculations, pump components, etc., can solve problems such as heavy test workload, and achieve the effects of facilitating digestion and absorption, improving design quality, and shortening the research and development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

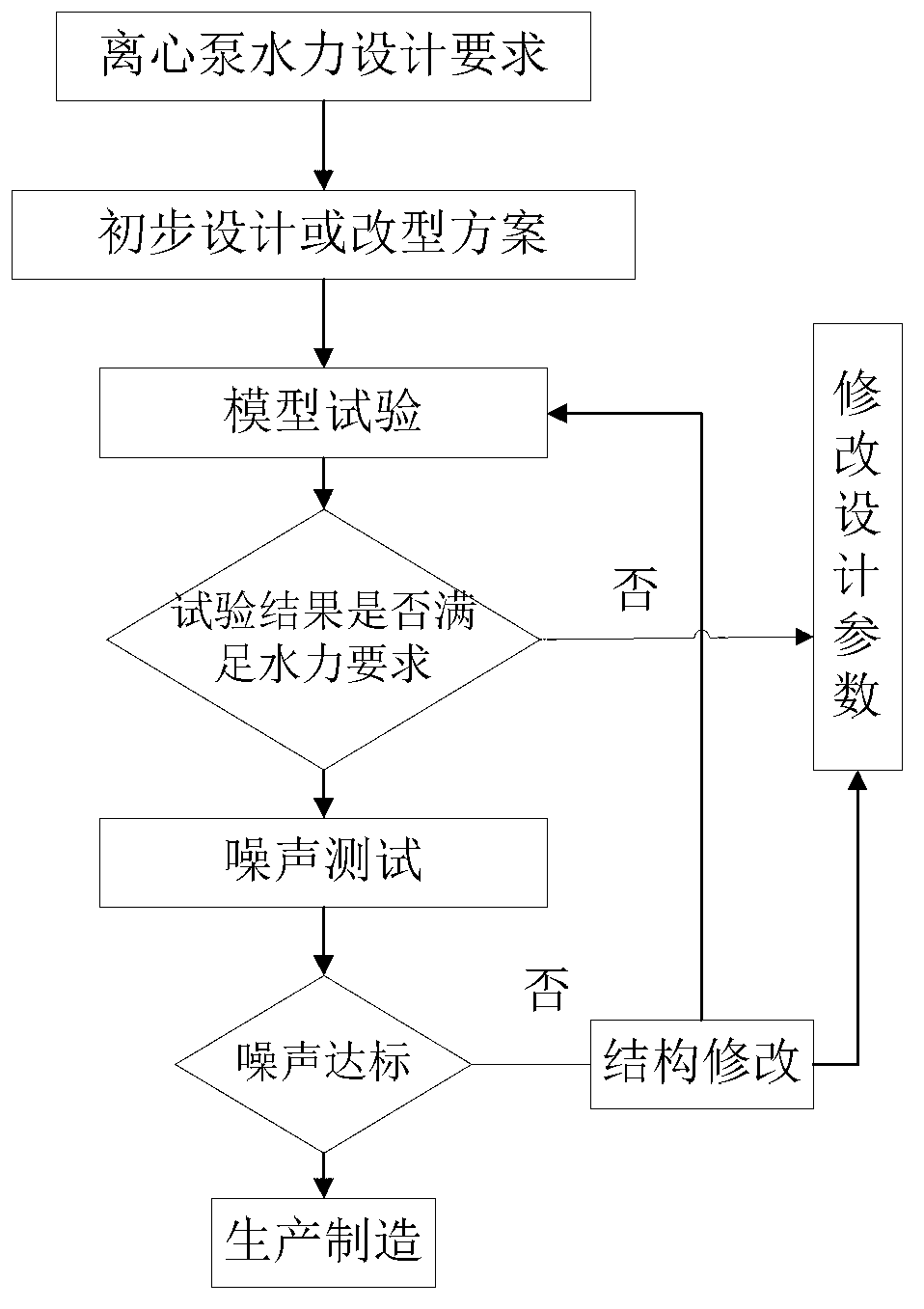

[0020] to combine figure 1 The hydraulic design process of the traditional low specific speed centrifugal pump is mainly based on experience, preliminary design or modification plan, model test, after the test results meet the hydraulic requirements, the noise test is carried out to check whether the noise meets the standard, and according to whether it meets the standard, make corrections, and finally Manufactured on an ever-revised basis.

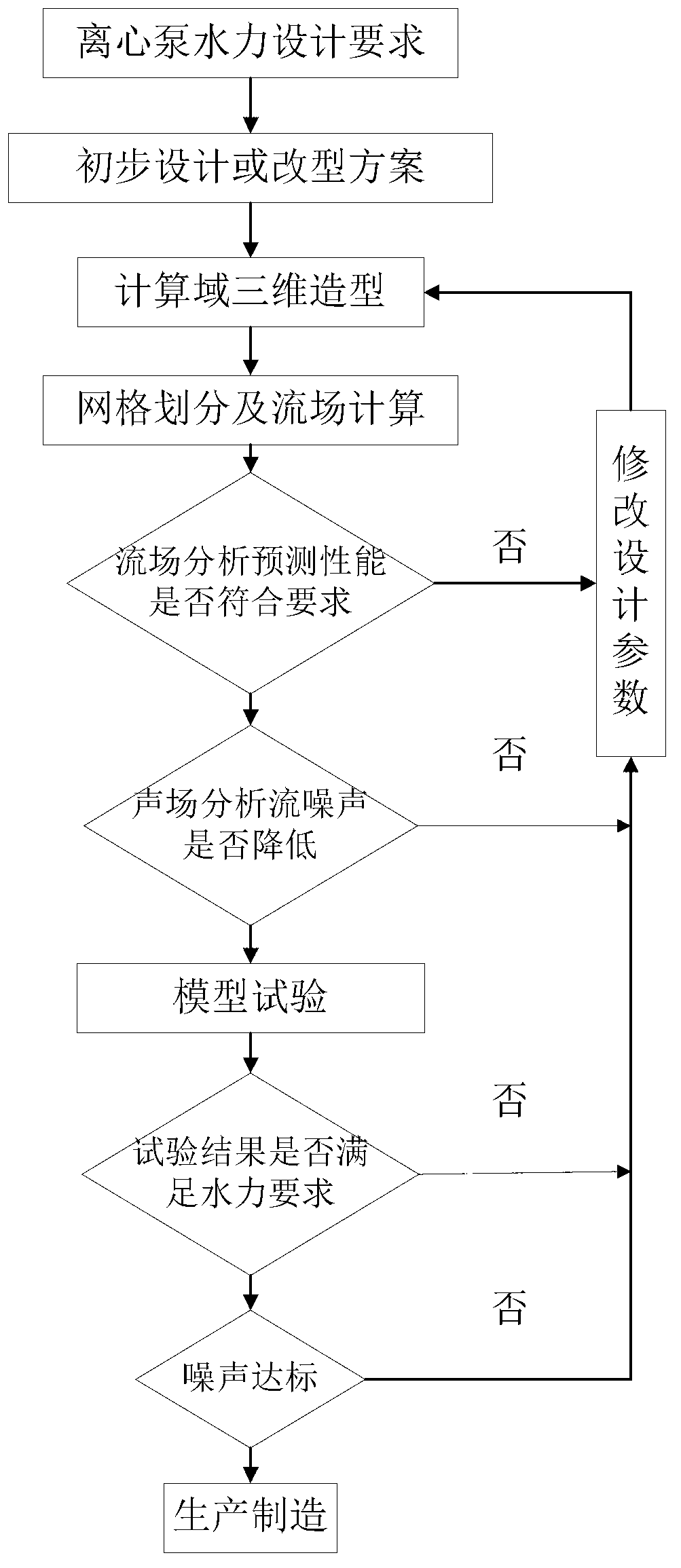

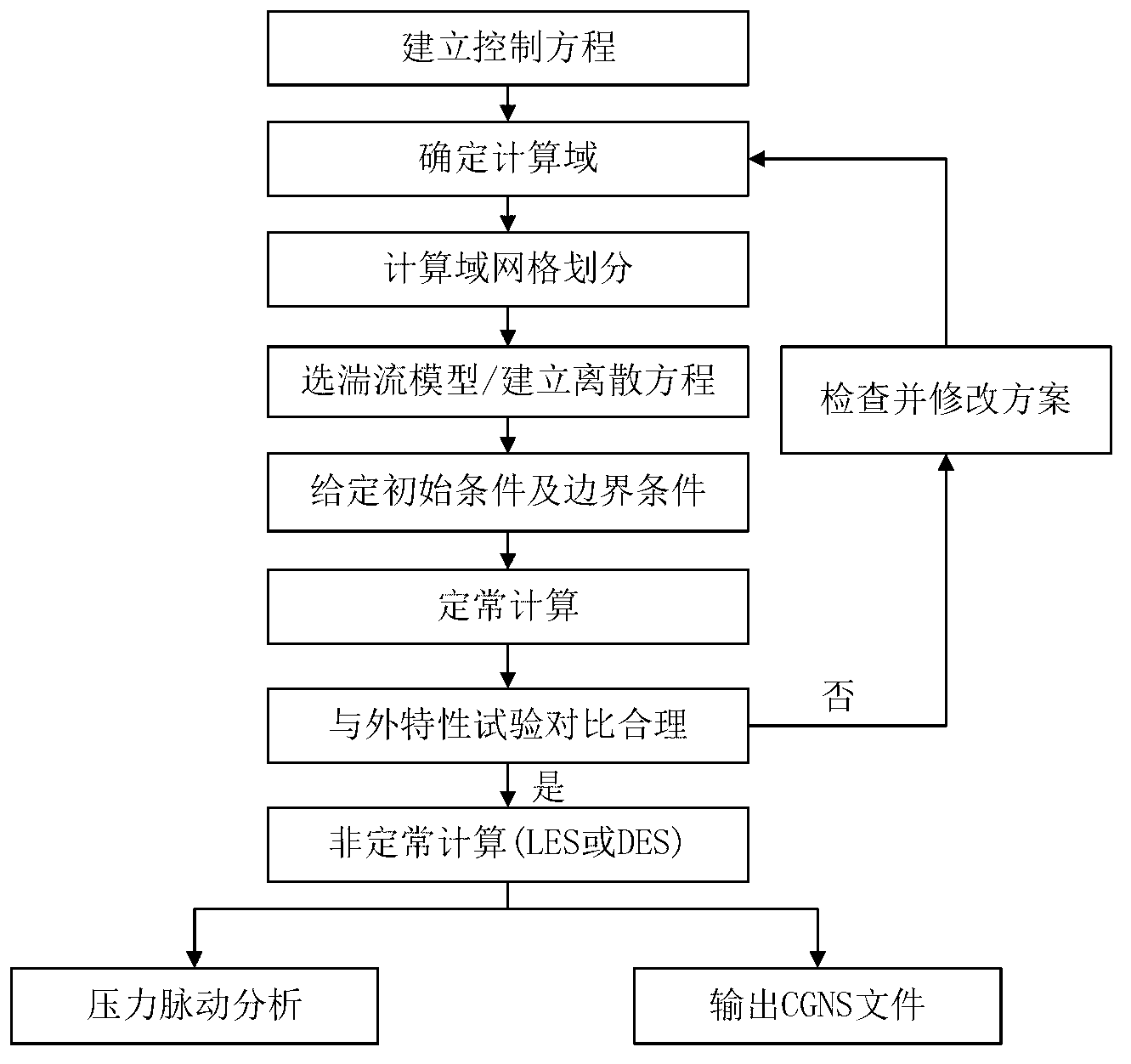

[0021] to combine figure 2 , the low-noise hydraulic design method adopted in the present invention, its implementation approach introduces numerical simulation, and adds acoustic optimization links in the design process. Performance prediction is based on Computational Fluid Dynamics (CFD) method, the process of which is as follows image 3 shown. Flow noise prediction adopts a coupling algorithm bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com