Semi-physical real-time simulation system of airplane reverse thrust hydraulic unit

A hydraulic device and real-time simulation technology, which is applied to the simulation device of space navigation conditions, transportation and packaging, electrical testing/monitoring, etc., can solve the problems of inability to carry out physical testing, high testing costs, and great manpower, material and financial resources. Achieve the effects of realizing 3D real-time animation display, shortening the development and analysis cycle, and reducing testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

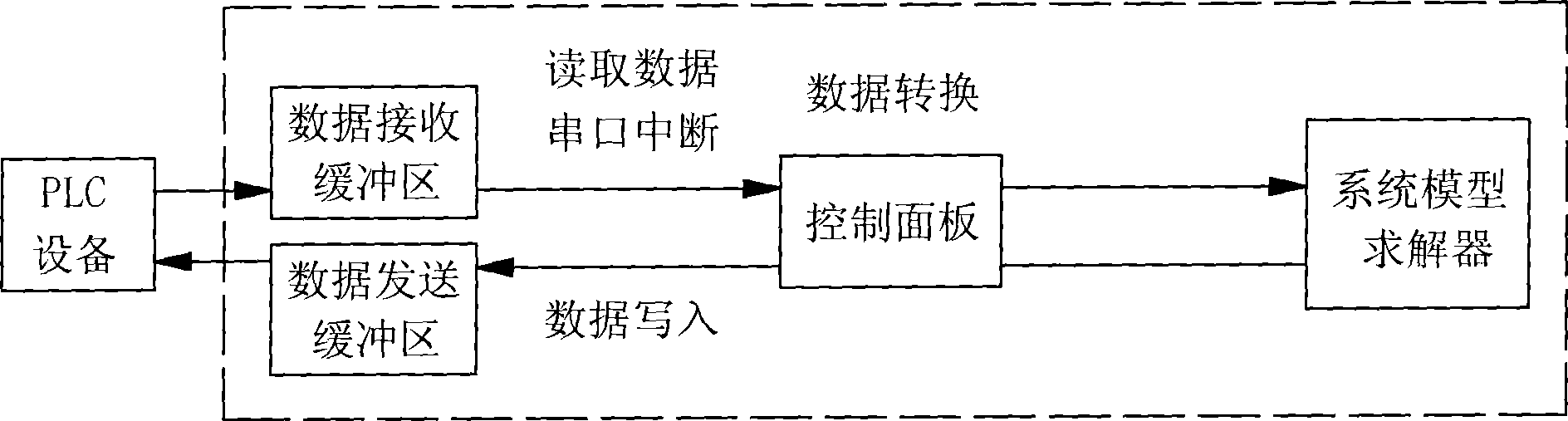

[0031] See attached figure 1 And attached figure 2 Shown, a kind of aircraft anti-thrust hydraulic device semi-physical real-time simulation system, hardware includes desktop computer DELL OPTIPLEX755 (Core 2 Duo processor, 2G memory, ATi2400 graphics card, etc.), Siemens PLC system (CPU312, 4-way analog input and output modules, digital input and output interfaces, etc.). The software platform is MWorks, and the modeling language Modelica.

[0032] 1) System modeling

[0033] The various hydraulic component models and electrical component models established on MWorks in Modelica language are connected with each other according to the design drawings to construct the entire reverse thrust hydraulic system model. Under the condition that the input and output volumes are fixed, the internal sub-models and connecting lines of the reverse thrust hydraulic system model can be adjusted and tested at any time.

[0034] according to figure 2 Aircraft anti-thrust hydraulic syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com