Water grate capable of preventing evaporation of water

A technology of water grates and drainage holes, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve the problems of troublesome handling, high incidence of structural failures, low height, etc., and achieves the effect of simple structure and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific example

[0011] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

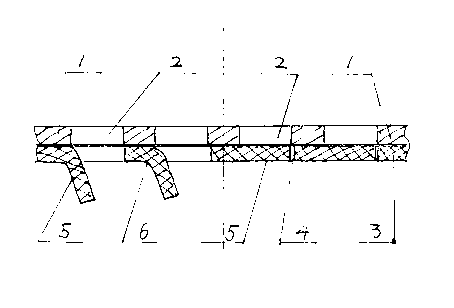

[0012] With reference to the accompanying drawings (the left side of the center line is the opened check valve 5, and the right side of the center line is the closed check valve 5), the water grate 1 with several rectangular drainage holes 2 is formed by stamping a stainless steel plate, and the rectangular drainage The hole 2 is of a shape that facilitates the installation of the check valve 5 . Water grate 1 bottom is provided with rubber plate 3, and this rubber plate 3 requires good elasticity, thickness is suitable, and promptly the weight of water can bend it, does not have pressure and can restore original state. Thin rubber plate 3 is provided with the otch 4 that three sides are connected on the corresponding position of drainage hole 2, promptly cuts out two wide one long otch 4 on rubber plate 3, has fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com