Speed-controllable gravity lowing winch provided with built-in gear reducer

A technology of gravity lowering and reducer, which is applied in hoisting devices and spring mechanisms, etc., can solve the problems of reducing the utilization rate of port cargo yards, occupying a large space, and high manufacturing costs, so as to improve the efficiency of loading and unloading operations, safe and reliable use, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

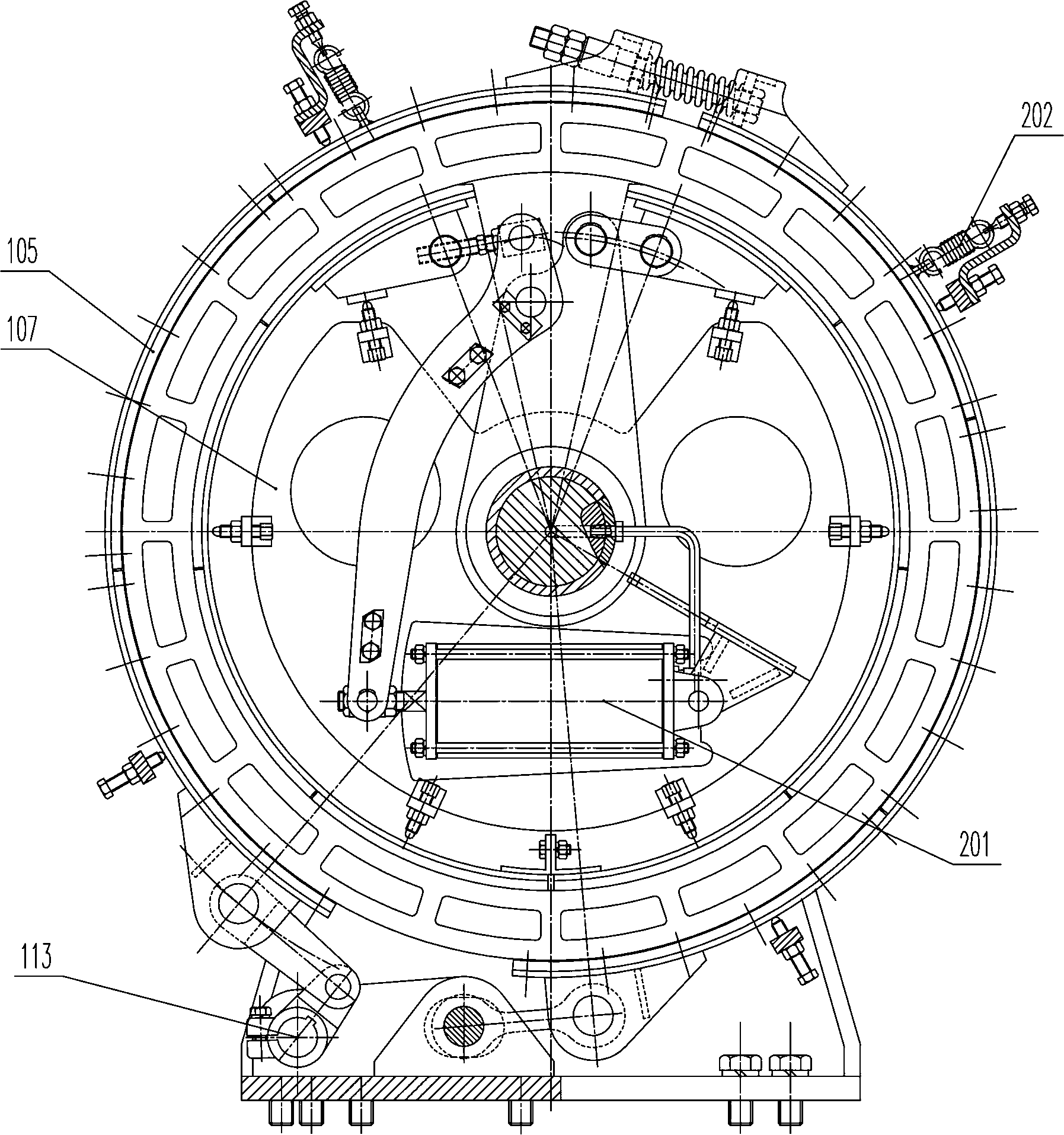

[0019] see Figure 1-2 , a gravity lowering winch with a built-in reducer and controllable speed, a transmission shaft 110, a bearing seat 112, a reel 104 and a hoisting support 102, a built-in reducer 101 is arranged in the reel, and the input end shell of the built-in reducer The body is fixed on the winch support, the transmission shaft is fixedly connected to the output end of the built-in reducer, and the drive shaft is arranged coaxially with the input shaft of the built-in reducer, and the built-in reducer has a front end shell and a reducer lower box 108, The lower case of the reducer is connected to the output end housing of the built-in reducer, the lower case of the reducer is supported on the transmission shaft through the second bearing 109, and the reel is respectively supported on the built-in reducer through the third bearing 114 and the fourth bearing 115 On the front end shell of the reducer and the tail end of the lower box of the reducer, the transmission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com