Pneumatic tire tread structure for uneven ground

A technology for pneumatic tires and tire treads, applied in tire tread/tread pattern, tire parts, transportation and packaging, etc. Traction performance, improved comfort, the effect of ensuring comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

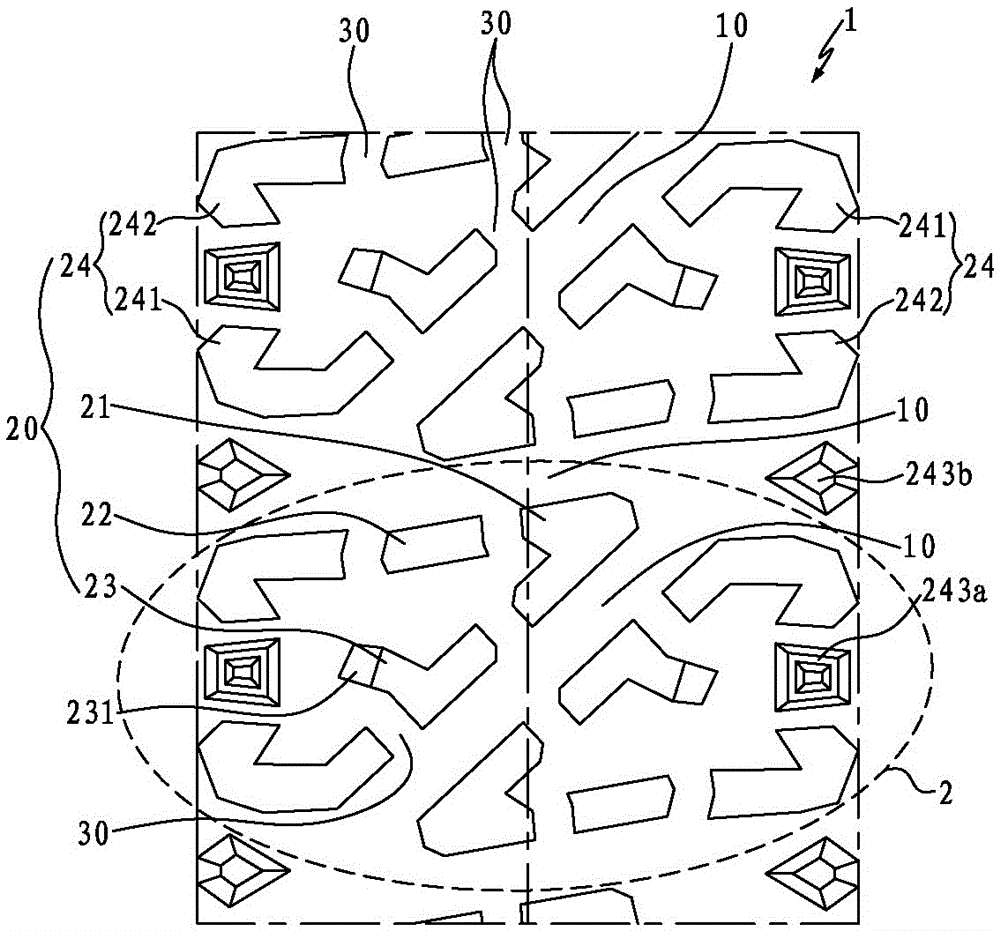

[0032] Such as figure 1 As shown, the present invention discloses a pneumatic tire tread structure for uneven ground. The tire tread 1 is composed of several pattern units 2 uniformly distributed along the tire circumferential direction. Two △-shaped pattern block groups 20 symmetrical to the center and tire axis, in figure 1 Among them, the transverse direction is the tire axial direction; each △-shaped block group 20 spans the center of the tire tread, and each △-shaped block group 20 is formed by a V-shaped main groove 10 across the center of the tire tread.

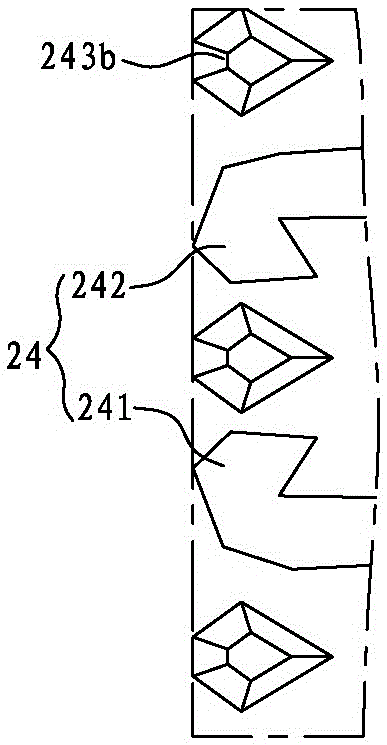

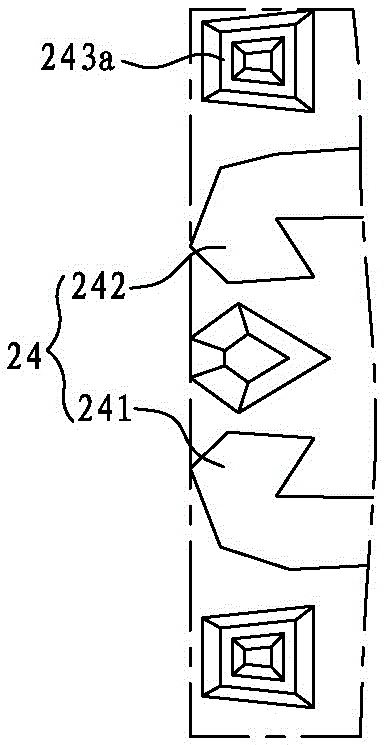

[0033] The triangle of each △-shaped block group 20 is close to a right-angled triangle, which is divided into a central pattern block 21, a transition pattern block 22, an interval pattern block 23 and a shoulder pattern block 24 by an auxiliary groove 30; wherein the center pattern block 21 is located at a right angle At the angle between the long right-angled side and the hypotenuse of the triangle, the central pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com