Non-vacuum continuous production equipment and process of copper chromium zirconium alloy

A copper-chromium-zirconium, non-vacuum technology is applied in the production field of copper-chromium-zirconium alloy, which can solve the problems of difficult production scale, long production cycle and high vacuum production cost, and achieve the effect of realizing continuous production and reducing production difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

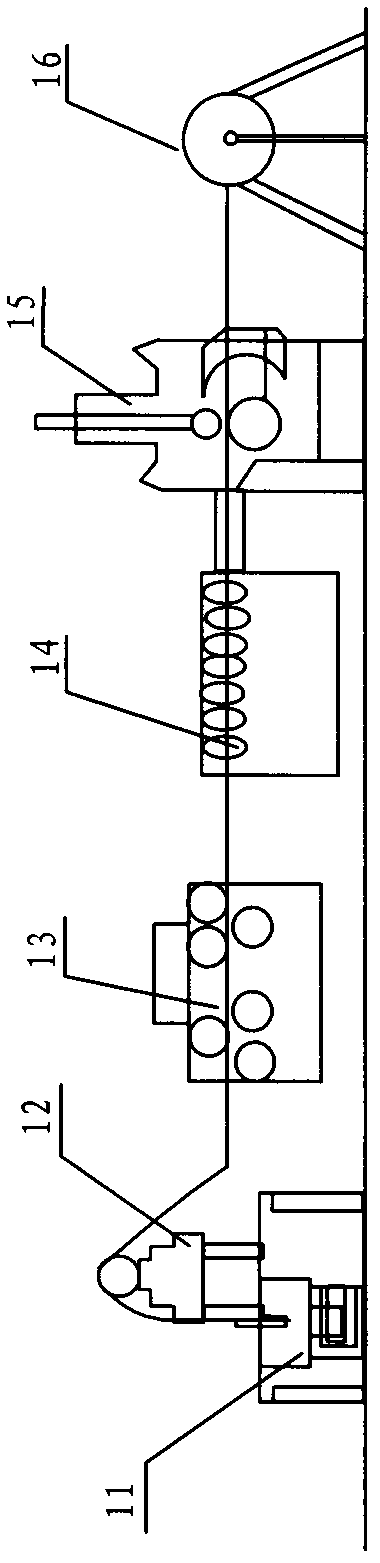

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0023] see figure 1 , is a schematic diagram of non-vacuum continuous production equipment for a copper-chromium-zirconium alloy disclosed in the present invention, the equipment includes a melting and casting furnace 11, and the melting and casting furnace is a non-vacuum submerged flow type power frequency induction furnace, which includes a melting furnace, a static chamber and There are three parts of the holding furnace, and a submerged channel valve is arranged between the melting furnace and the static chamber.

[0024] An upward-drawing continuous casting machine 12 is arranged above the smelting furnace, and an upward-drawing continuous casting machine 12 is provided with an upward-drawing crystallizer, and the upward-drawing crystallizer extends into the smelting fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com