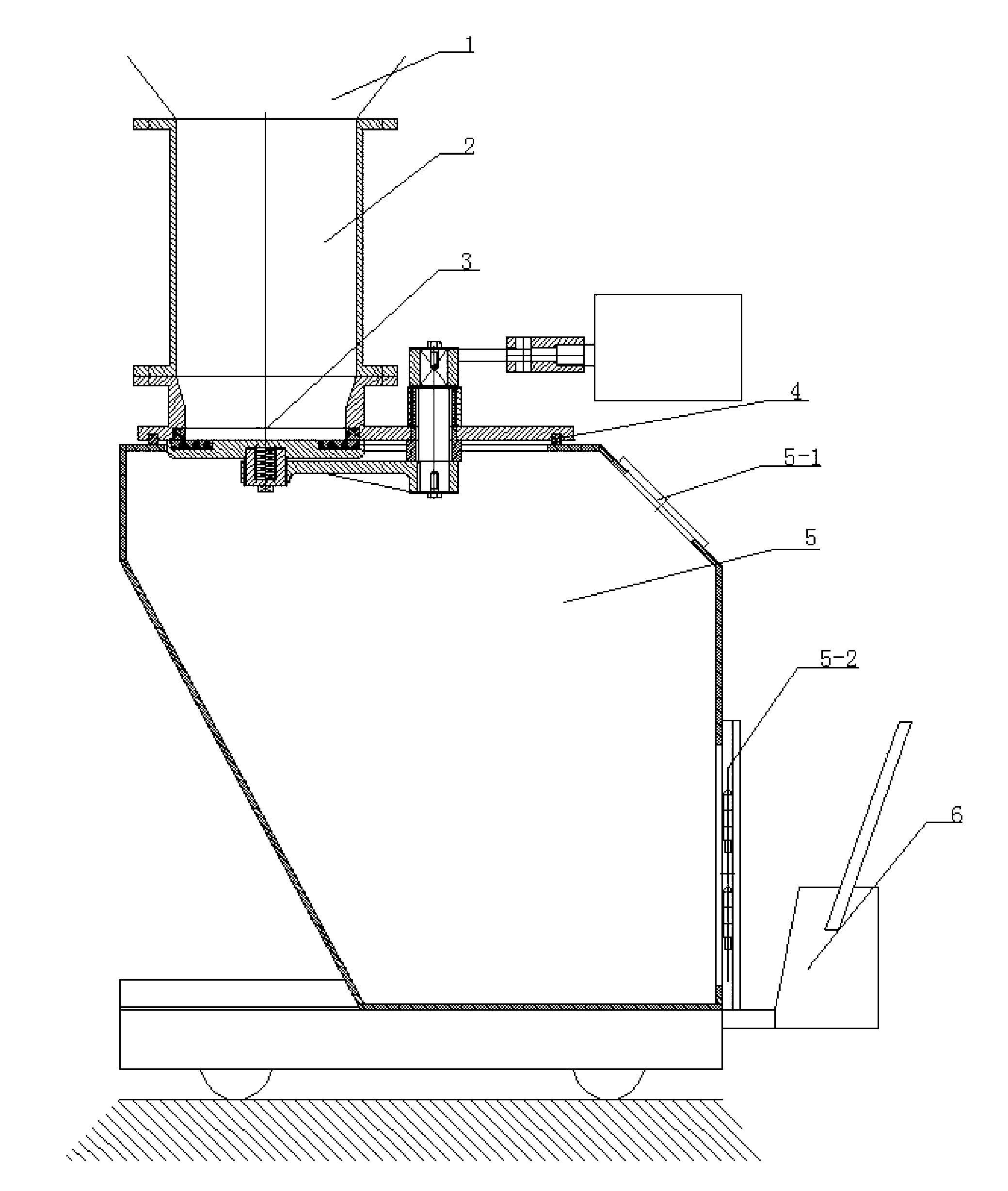

Full-sealed type slag discharging system of coal mill

A coal mill, fully sealed technology, applied in the direction of grain processing, etc., can solve the problems of leakage, aging, dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to achieve the above purpose of the present invention, the coal mill fully sealed slag discharge system uses the following methods and principles. A first pipeline is arranged at the slag outlet of the coal mill, and the first pipeline communicates with the slag outlet of the coal mill. A spring-jack-up sealed wear-resistant ceramic valve is installed under the first pipeline. The advantage of this valve is that it uses engineering wear-resistant ceramics as the sealing pair, which greatly enhances the wear resistance of the valve and avoids damage to the valve caused by switch wear. Internal leakage. At the same time, this valve adopts the form of spring to lift the ceramic gate for sealing. By adjusting the elasticity of the spring, the valve can be sealed more tightly, avoiding the external leakage caused by the poor sealing of the valve. Below the wear-resistant ceramic valve, the fluorine rubber sealing ring is directly embedded on the lower flange of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com