Current Transformer Type Transmission Line Conductor Thermal Icing Device Compensated by Secondary Capacitor

A technology of current transformers and transmission lines, which is applied in the direction of circuit devices, cable installation, electrical components, etc. It can solve the problems of increasing power loss, increasing the capacity of ice-melting devices, and difficulty in providing power, and achieves the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

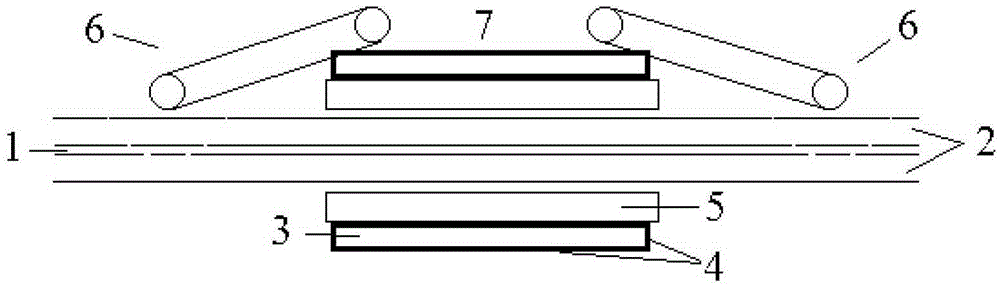

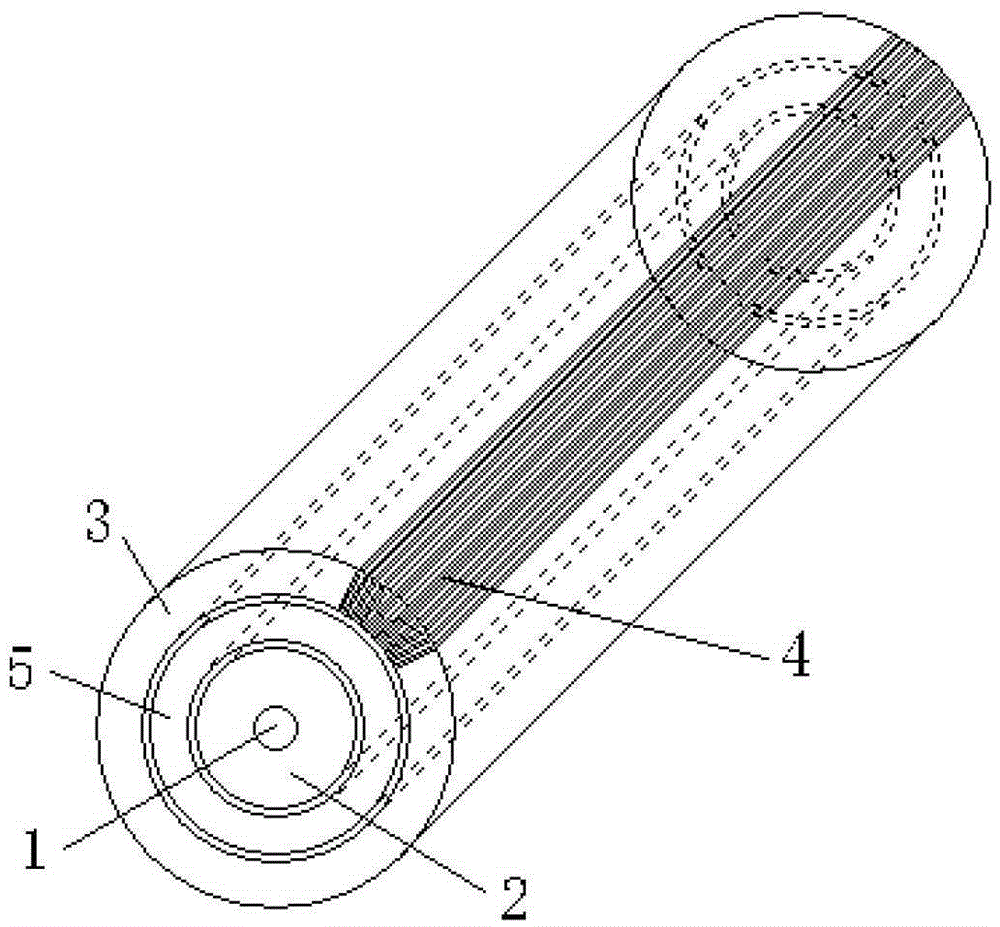

[0056] Set the RMS value I of the primary current of the transmission line conductor 1m = 300A.

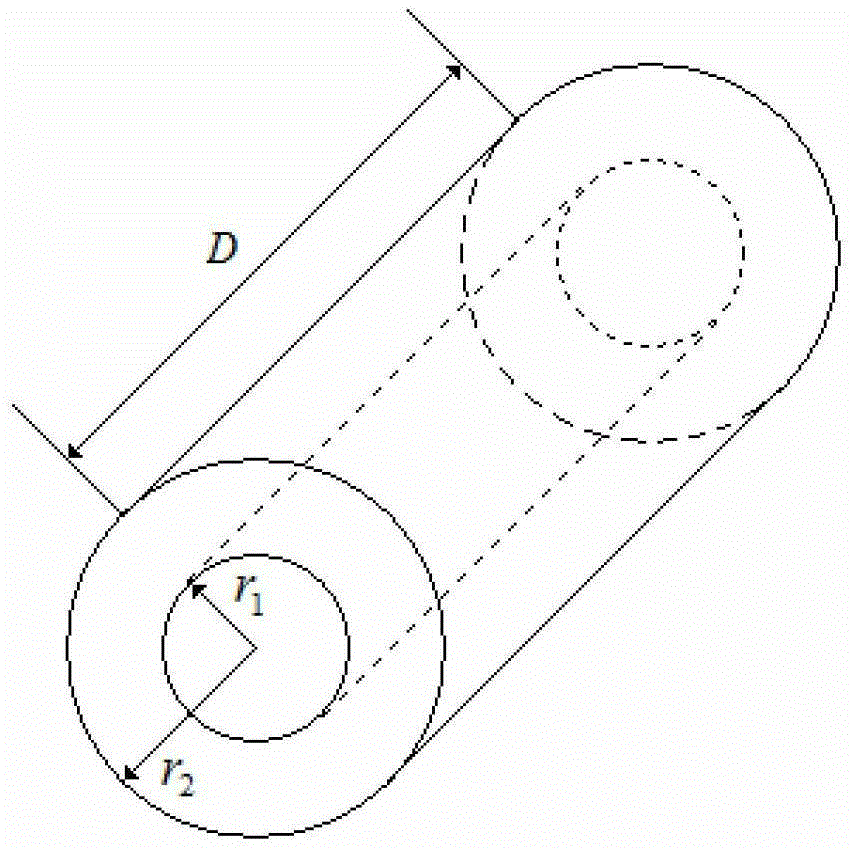

[0057] Core inner radius r 1 =0.1m, outer radius r 2 =0.12m, length D=0.4m, secondary coil turns n=200, air gap δ=0.0005m, core relative permeability μ r =3000, load resistance R L = 48.4Ω. Choose enameled wire with copper core nominal diameter 2.02mm, copper core area 3.205mm 2 , kilometer resistance 5.47Ω, coil internal resistance R 0 = 0.0175Ω.

[0058] The self-inductance of the secondary circuit is L=0.5508H, the mutual inductance of the primary circuit and the secondary circuit is M=0.00275H, the compensation capacitor is C=17μF, and the effective value of the secondary current is I 2m =5.289A, output power P=1354W.

[0059] The output power is enough to melt the ice on the wire.

Embodiment 2

[0061] Set the RMS value I of the primary current of the transmission line conductor 1m =400A.

[0062] Core inner radius r 1 =0.1m, outer radius r 2 =0.12m, length D=0.3m, secondary coil turns n=220, air gap δ=0.0005m, core relative permeability μ r =3000, load resistance R L = 48.4Ω. Choose enameled wire with copper core nominal diameter 2.02mm, copper core area 3.205mm 2 , kilometer resistance 5.47Ω, coil internal resistance R 0 = 0.0144Ω.

[0063] The self-inductance of the secondary circuit is L=0.4998H, the mutual inductance of the primary circuit and the secondary circuit is M=0.00227H, the compensation capacitor is C=21.3μF, and the effective value of the secondary current is I 2m =5.818A, output power P=1638W.

[0064] The output power is enough to melt the ice on the wire.

Embodiment 3

[0066] Set the RMS value I of the primary current of the transmission line conductor 1m =500A.

[0067] Core inner radius r 1 =0.1m, outer radius r 2 = 0.12m, length D = 0.2m, secondary coil turns n = 250, air gap δ = 0.0005m, core relative permeability μ r =3000, load resistance R L = 48.4Ω. Choose enameled wire with copper core nominal diameter 2.02mm, copper core area 3.205mm 2 , kilometer resistance 5.47Ω, coil internal resistance R 0 = 0.0109Ω.

[0068] The self-inductance of the secondary circuit is L=0.4303H, the mutual inductance of the primary circuit and the secondary circuit is M=0.00172H, the compensation capacitor is C=25μF, and the effective value of the secondary current is I 2m =5.31A, output power P=1469W.

[0069] The output power is enough to melt the ice on the wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com