Simulation method for fluid mixing state

A fluid model and mixing technology, applied in CAD numerical modeling, special data processing applications, instruments, etc., can solve the problems of low filling rate, not representing the ideal mixing state, etc., to achieve the effect of improving development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

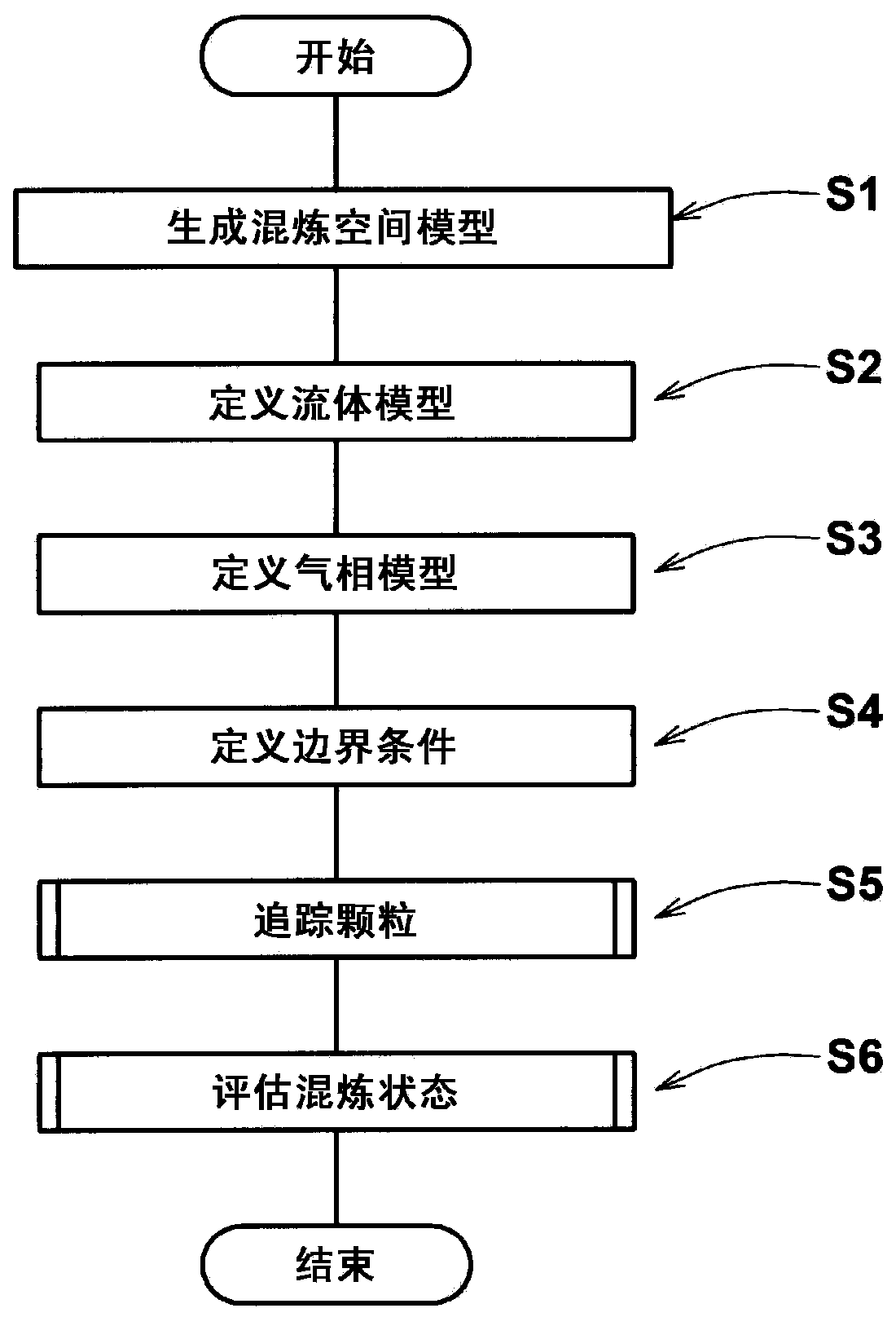

[0046] The present invention is directed to an analysis method for evaluating the kneading state of a fluid by using a computer (not shown).

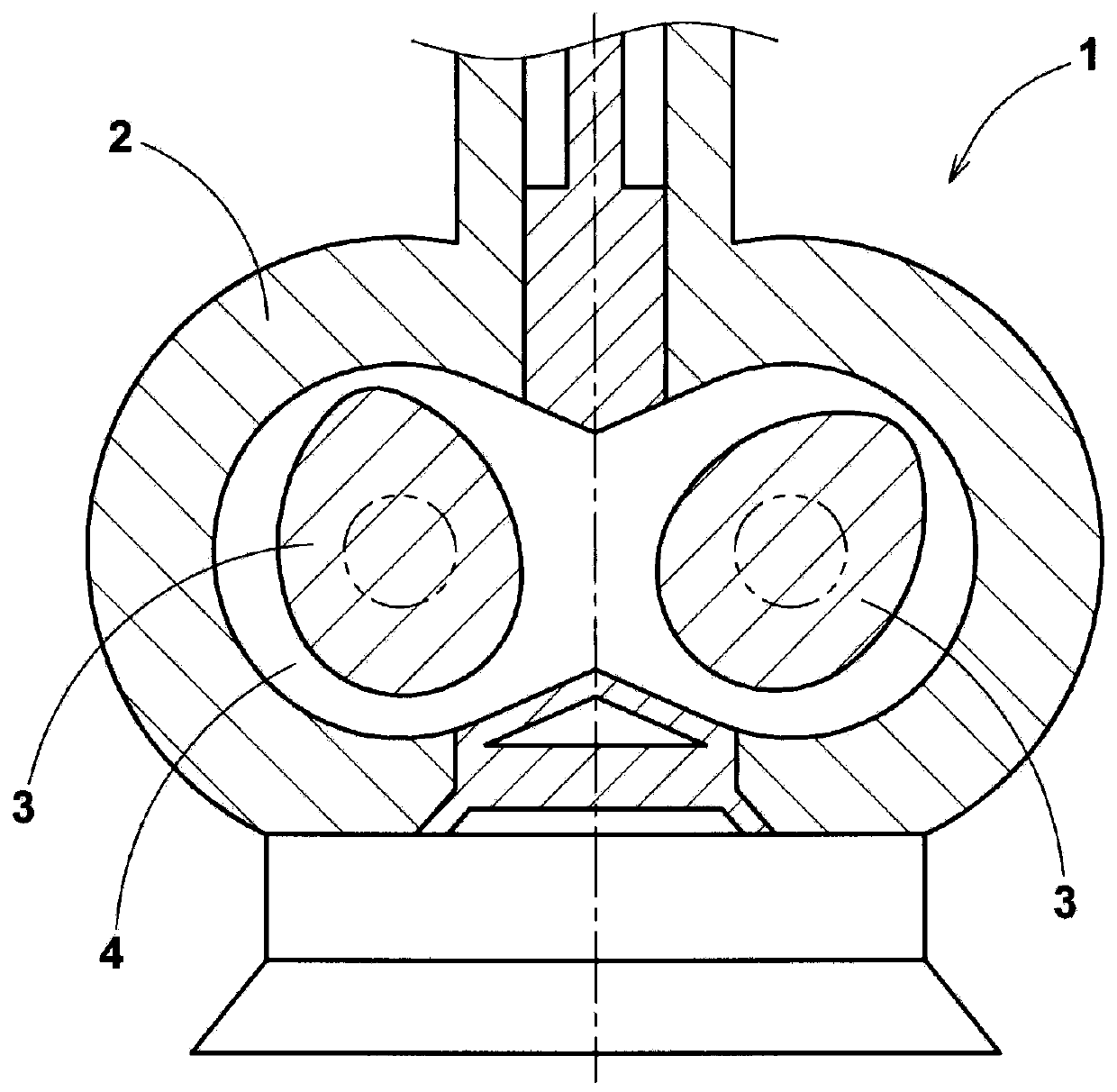

[0047] For example, before molding a rubber material or a numerical material, kneading is performed. During kneading, raw materials such as chemicals, fine particles, etc. are wetted with a liquid binder and dispersed uniformly into a homogeneous mixture. This mixing process is typically performed by figure 1 The Banbury kneader 1 shown is performed.

[0048] Banbury Mixer 1 includes:

[0049] The housing 2 defines the inner surface of a kneading space 4 in which raw materials such as rubber material etc. are kneaded, and a pair of rotors 3 which are rotatable in the kneading space 4 .

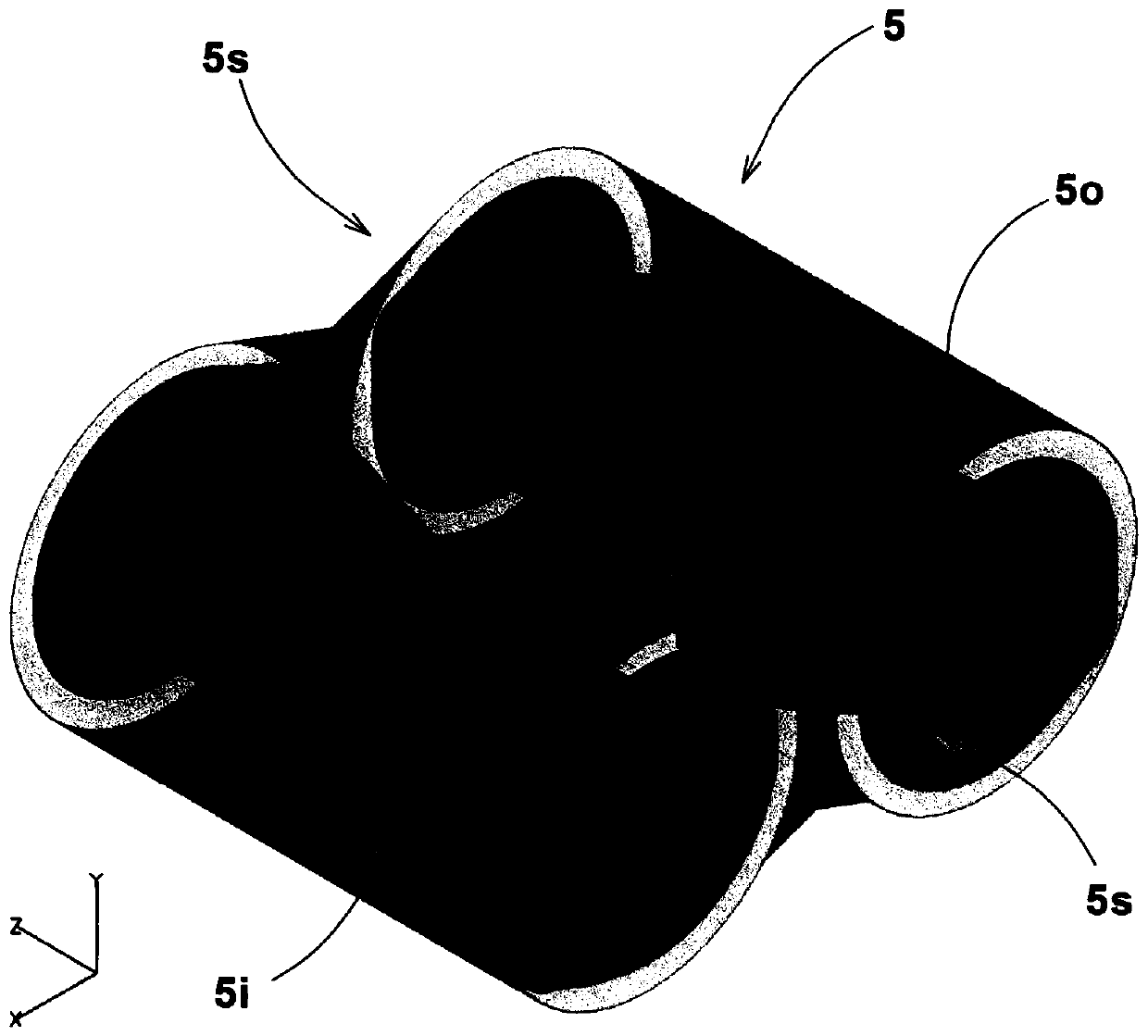

[0050] The kneading space 4 in this example has a figure 8-like sectional shape. However, the kneading space is not limited t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com