Omni-directional imaging device and method

A panoramic imaging and panorama technology, applied in optics, instruments, wide-screen photography, etc., can solve the problems of difficulty in design, processing and system installation, low resolution, high price, etc., to improve pixel utilization and improve Image resolution, effect of reducing design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Panoramic imaging device with flat imaging surface

[0026] Such as image 3 As shown, the focal length obtained after optimization design is in the range of -30mm to -10mm, and the F number is in the range of 6 to 12. The catadioptric panoramic ring lens working in the visible light band has a circular image plane in the On the plane, the diameter of the outer ring of the ring size ranges from 60 to 80 mm, and the diameter of the inner ring ranges from 10 to 30 mm. The tapered optical fiber panel with a reduction ratio of 5:1, with a square at the big end and a rectangle at the small end (the ends of the big and small ends are both flat), transmits the image on the circular image plane of the catadioptric panoramic ring lens to the CCD \CMOS image sensor.

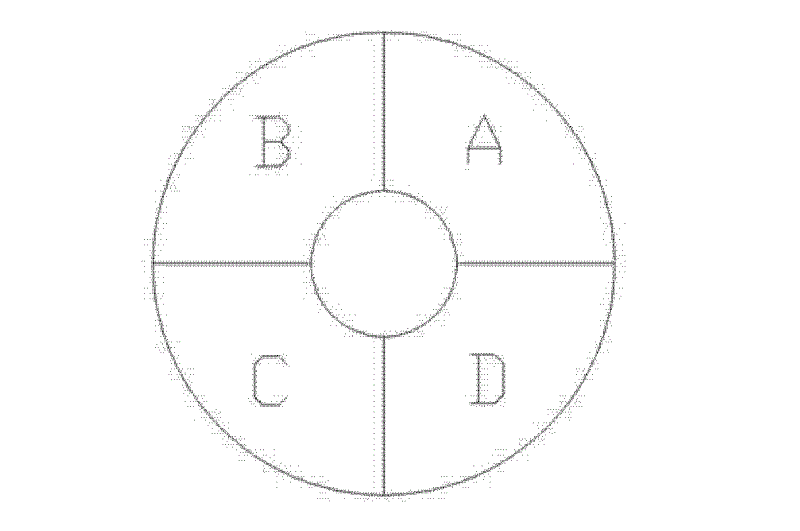

[0027] Such as Figure 4 As shown in , the circular image plane is evenly divided into four fan-shaped sub-image planes (A, B, C, D). Such as Figure 5 As shown, each sub-image area expanded into a ...

Embodiment 2

[0029] Example 2 Panoramic imaging device with spherical imaging surface

[0030] Such as Figure 6 As shown, the focal length obtained after optimization design is in the range of -30mm to -10mm, and the F number is in the range of 6 to 12. The catadioptric panoramic ring lens working in the visible light band has a circular image plane in the On a spherical surface, the diameter of the outer ring is 60-80 mm, and the diameter of the inner ring is 10-30 mm. With a reduction ratio of 5:1, the large end is fan-shaped, and the small end is rectangular (the end surface of the large end is a spherical surface, and the end surface of the small end is a flat surface). The image above is passed to the CCD\CMOS image sensor.

[0031] The circular image surface on the spherical imaging surface of the catadioptric panoramic ring lens is evenly divided into 4 fan-shaped sub-image surfaces. Each sub-image plane is matched with a tapered optical fiber panel whose large end is fan-shap...

Embodiment 3

[0033] Example 3 panoramic imaging method

[0034] The 360-degree scene around the first surface of the catadioptric panoramic ring lens is imaged by the system and a circular image surface (on a spherical or flat surface) is obtained at the rear image surface of the system, which is divided into 4 evenly Fan-shaped sub-image planes, the images on each sub-image plane are transmitted to the corresponding CCD\CMOS image sensors through the matching tapered optical fiber panels, and the images on each CCD\CMOS image sensors are expanded into The rectangular images are spliced sequentially according to their order on the circular imaging surface to obtain a rectangular panoramic image. Finally, the panoramic image is displayed by the image display unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com