Heat storage and exchange method used for recovering waste heat of smoke with flying ash

A flue gas waste heat and heat method technology, which is applied in the field of flue gas waste heat recovery, can solve problems such as deposition, blockage, and regenerator inoperability, and achieve the effects of simple structural design and operation, and low ash removal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

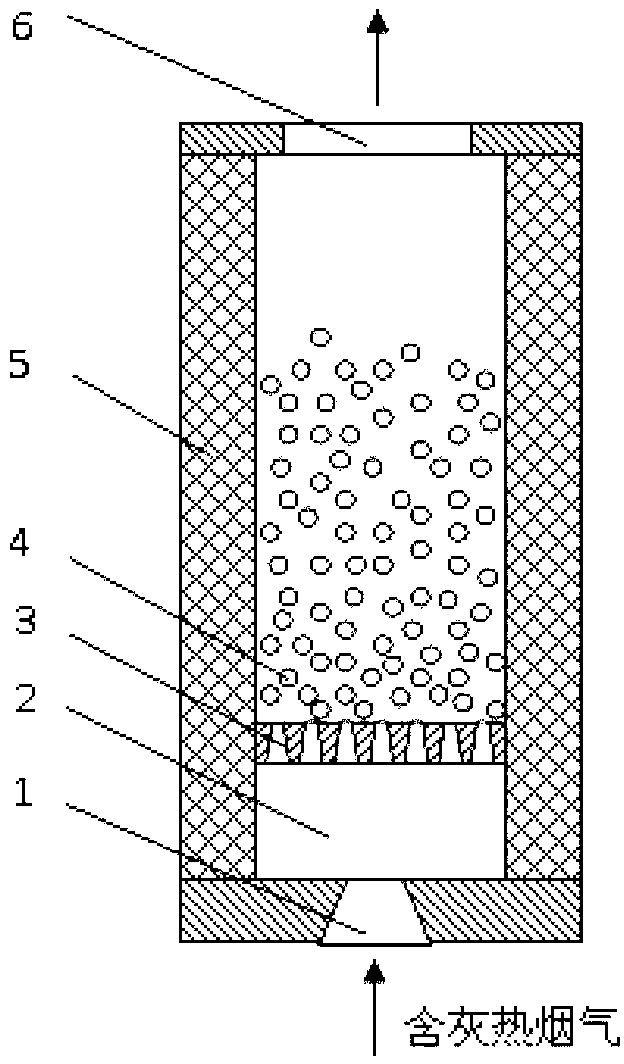

[0037] Such as figure 1 As shown, the method of this embodiment is as follows: first, before the flue gas containing fly ash enters the regenerator, reduce the fly ash entering the regenerator; secondly, accelerate the travel speed of the flue gas, and the flue gas enters the regenerator The refractory ball 4 bed is blown to increase the gap between the refractory ball 4, and the refractory ball 4 bed forms a fluidized bed, and the heat exchange between the flue gas and the refractory ball 4 makes the heat stored in the In the refractory ball 4, the fly ash entering the regenerator flows out of the regenerator, so as to avoid blocking the circulation channel.

[0038] The way to reduce the fly ash entering the regenerator is: install an air chamber 2 before the regenerator, and at the same time, install an air distribution plate 3 at the entrance of the regenerator, when the flue gas containing fly ash enters the air chamber 2 And when it flows through the air distribution pl...

Embodiment 2

[0056] This embodiment is a device based on the method of Embodiment 1, such as figure 1 As shown, it includes: regenerator, air chamber 2, air distribution plate 3 and refractory ball 4, wherein: the entrance of the regenerator is provided with an air distribution plate 3, the front is provided with an air chamber 2, and the circulation channel of the regenerator There are refractory balls 4 in it.

[0057] The air inlet of the air chamber 2 is provided with a nozzle, and the structure of the nozzle is a trapezoidal structure with a wide inlet at the bottom and a narrow outlet at the top.

[0058] Evenly have some through-holes on the described air distribution plate 3, the structure of this through-hole is the trapezoidal structure that bottom entrance is wide and top exit is narrow.

[0059] The outside of the heat storage chamber is provided with an insulating layer 5 .

[0060] The flue gas containing fly ash enters the air chamber 2 from the nozzle 1, and after being u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com