Quick exhaust valve of air cannon

An exhaust valve and air cannon technology, applied in valve details, valve device, valve shell structure and other directions, can solve the problems of slow discharge speed, affecting the use of air cannon, fast exhaust valve blockage, etc., to improve the gas discharge speed, The effect of prolonging the service life and avoiding internal clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

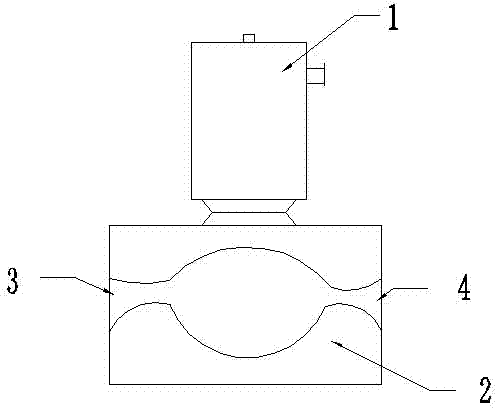

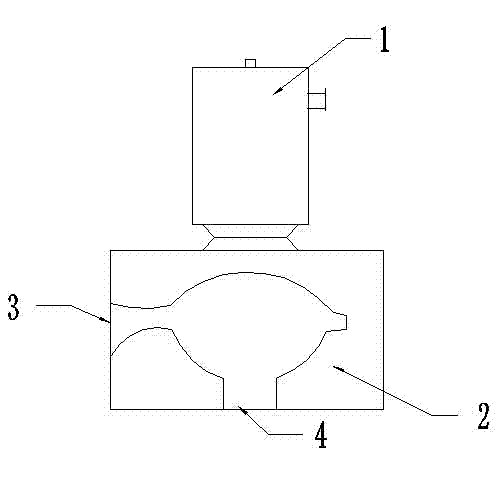

[0013] Such as figure 2 As shown, the quick exhaust valve of the present invention includes a magnetic head 1 and a valve body 2 connected to the magnetic head 1 , an air inlet 3 is provided at one end of the valve body 2 , and an air outlet 4 is provided at the lower end of the valve body 2 . Since the air outlet 4 is set at the lower end of the valve body 2, the gas can be directly discharged from the air outlet 4 provided at the bottom of the valve body 2 through the air inlet 3, which greatly improves the discharge speed; When the material returns, when the material enters the valve body 2 through the air outlet 4, it will be directly discharged from the air outlet 4 provided at the bottom of the valve body 2, so as to avoid the flow blockage inside the exhaust valve and ensure the normal use of the air cannon. The quick exhaust valve adopts a solenoid valve, and the signal input end of the quick exhaust valve is connected to the air cannon control module, and is controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com