Rotating plate type magnetic flowmeter with anti-blocking structure

A flowmeter and rotary plate technology, applied in the field of flowmeters, can solve the problems of affecting the measurement accuracy, disturbing the magnetic field of the magnetic flowmeter, blocking the magnetic flowmeter, etc., to achieve the effect of prolonging the service life, preventing internal clogging and strong moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the rubber material is as follows: mix polystyrene butadiene rubber and nanomaterials evenly, add vulcanizing agent and accelerator, vulcanize and form, the vulcanization temperature is 145°C, and the vulcanization time is 500s.

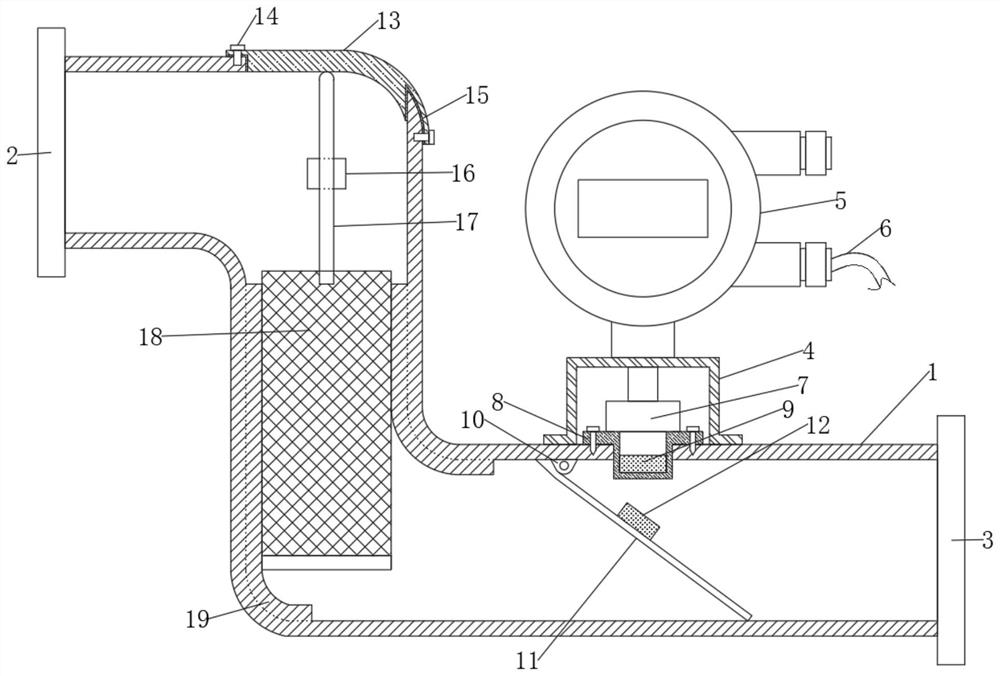

[0047] Further, the clips 16 are located on both sides of the front and back of the watch body 1, the thickness of the thickened pipe 19 is greater than the width of the clip 16, the filter bucket 18 is in sliding connection with the thickened pipe 19, and the pull rod 17 is in a sliding connection with the clip 16. The clamp 16 is a two-thirds ring structure, the pull rod 17 is an "n"-shaped structure, the inner diameter of the thickened pipe 19 is the same as the diameter of the filter barrel 18, and the watch body 1 is a "Z"-shaped structure, through the setting of the filter barrel 18 , separate the impurities entering the medium at the inlet flange 2, prevent metal impurities from being adsorbed on the second magn...

Embodiment 1

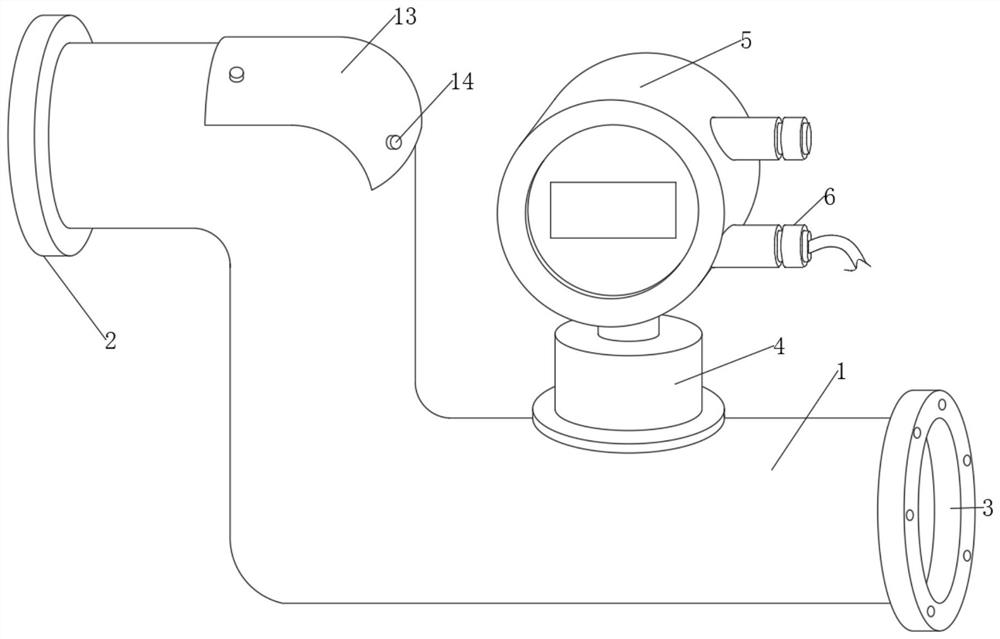

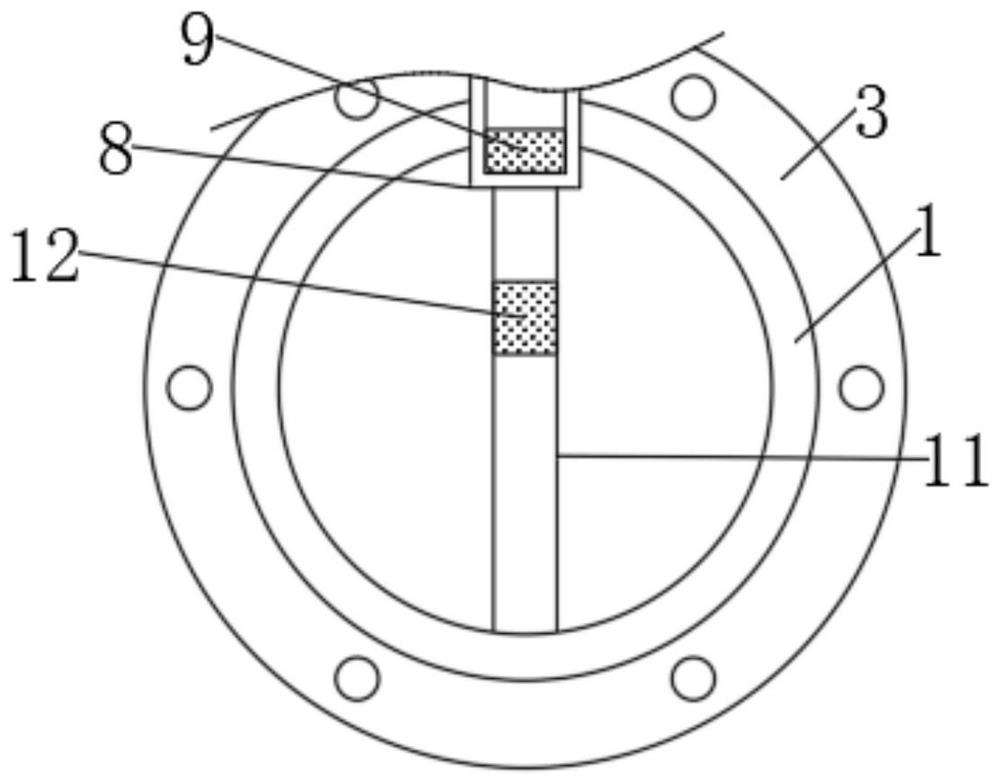

[0050] This embodiment provides a technical solution: a rotating plate magnetic flowmeter with an anti-blocking structure, including a meter body 1, an inlet flange 2, an outlet flange 3, a support 4, an accumulator 5, a terminal 6, Pressure sensor 7, magnetic base 8, first magnet 9, hinge bracket 10, rotating plate 11, second magnet 12, sealing cover 13, screw 14, sealing gasket 15, clip 16, pull rod 17, filter bucket 18 and thickening Pipeline 19, inlet flange 2 is fixedly installed on the left side of meter body 1, outlet flange 3 is fixedly installed on the right side of meter body 1, support 4 is fixedly installed on the outside of meter body 1, and the top of support 4 is provided with The totalizer 5 is provided with a terminal 6 on the outside of the totalizer 5, a pressure sensor 7 is provided inside the support 4, a magnetic base 8 is fixedly installed on the inside of the meter body 1, and the bottom of the magnetic base 8 is provided with a first Magnet 9, watch bo...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that the rubber material is different.

[0061] The rubber material includes the following raw materials in parts by weight: 75 parts of solution-polymerized styrene-butadiene rubber (LANXESS Chemical 5025-2HM), 15 parts of graphene oxide (Xianfeng Nano), 5 parts of sulfur (Luchu rubber), 2.5 parts of accelerator Agent CZ (CAS: 95-33-0). The styrene block content of the solution polystyrene butadiene rubber is 0.3wt%. The density of the graphene oxide is 0.9 g / mL at 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com