A steel pile method for controlling floor heave of gob-side entry retaining

A technology of gob-side retaining and steel piles, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc., and can solve the problems that can not fundamentally solve the problem of floor heave control of gob-side retaining, complex construction procedures, and limited control capabilities , to achieve the effect of reducing the action effect, simple support process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

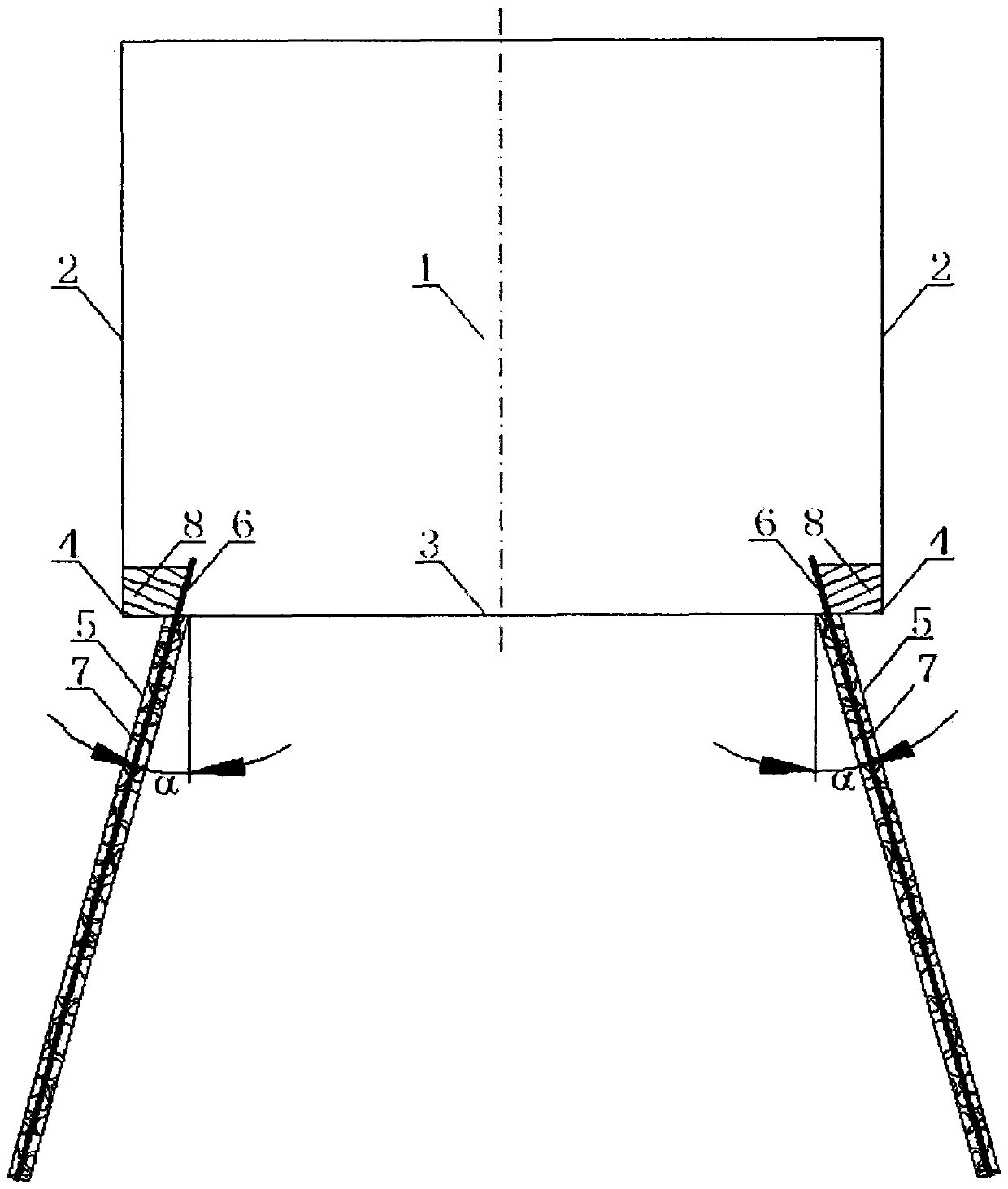

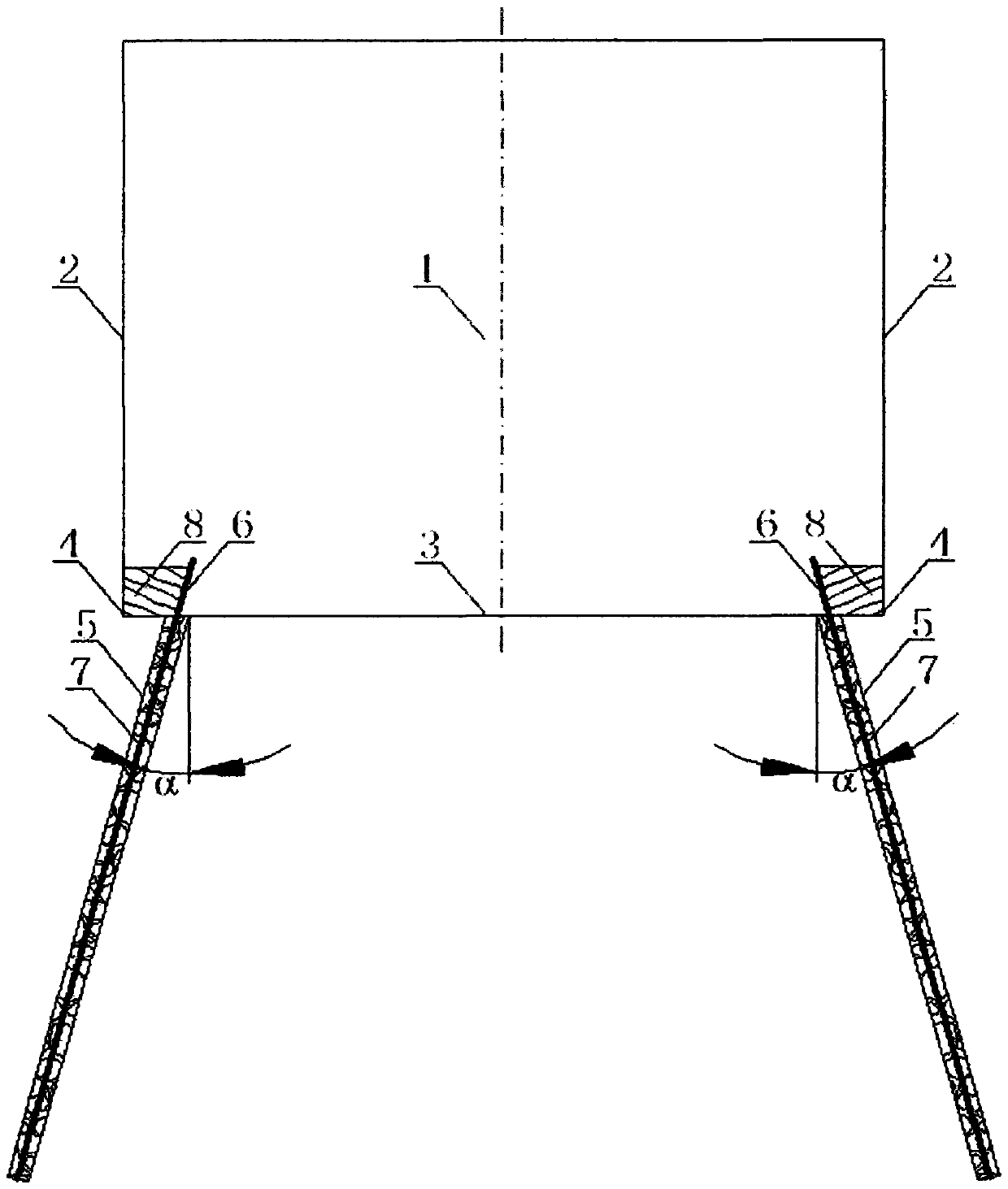

[0019] In order to alleviate the tense situation of excavation replacement, a mine adopts gob-side entry retention technology to retain the transportation roadway of this working face during the mining process of the coal mining face and use it as the return air roadway of the next working face. The monitoring results of surrounding rock deformation in roadways that have been implemented with gob-side entry retaining technology show that the bottom of the roadway can reach a maximum of 1000 mm before mining at the next working face, and the undercover method and reinforcement method cannot solve this problem. In order to ensure the implementation of the gob-side entry technology and the safe and efficient production of the mine, the steel pile method for controlling the bottom drum of the gob-side entry technology has been implemented for the roadway where the gob-side entry technology is being implemented. The following describes the embodiment of the invention in conjunction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com