Gas well remote high-voltage well switching device and control method thereof

A high-voltage switch and remote technology, applied in the direction of wellbore/well valve device, wellbore/well parts, earthwork drilling and production, etc., can solve the problem of heavy management and maintenance workload of gas wells, scattered well positions, and easy sand accumulation on the sealing contact surface and other issues to achieve the effect of reducing the consumption of manpower and material resources, improving the level of automation, and reducing the difficulty of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

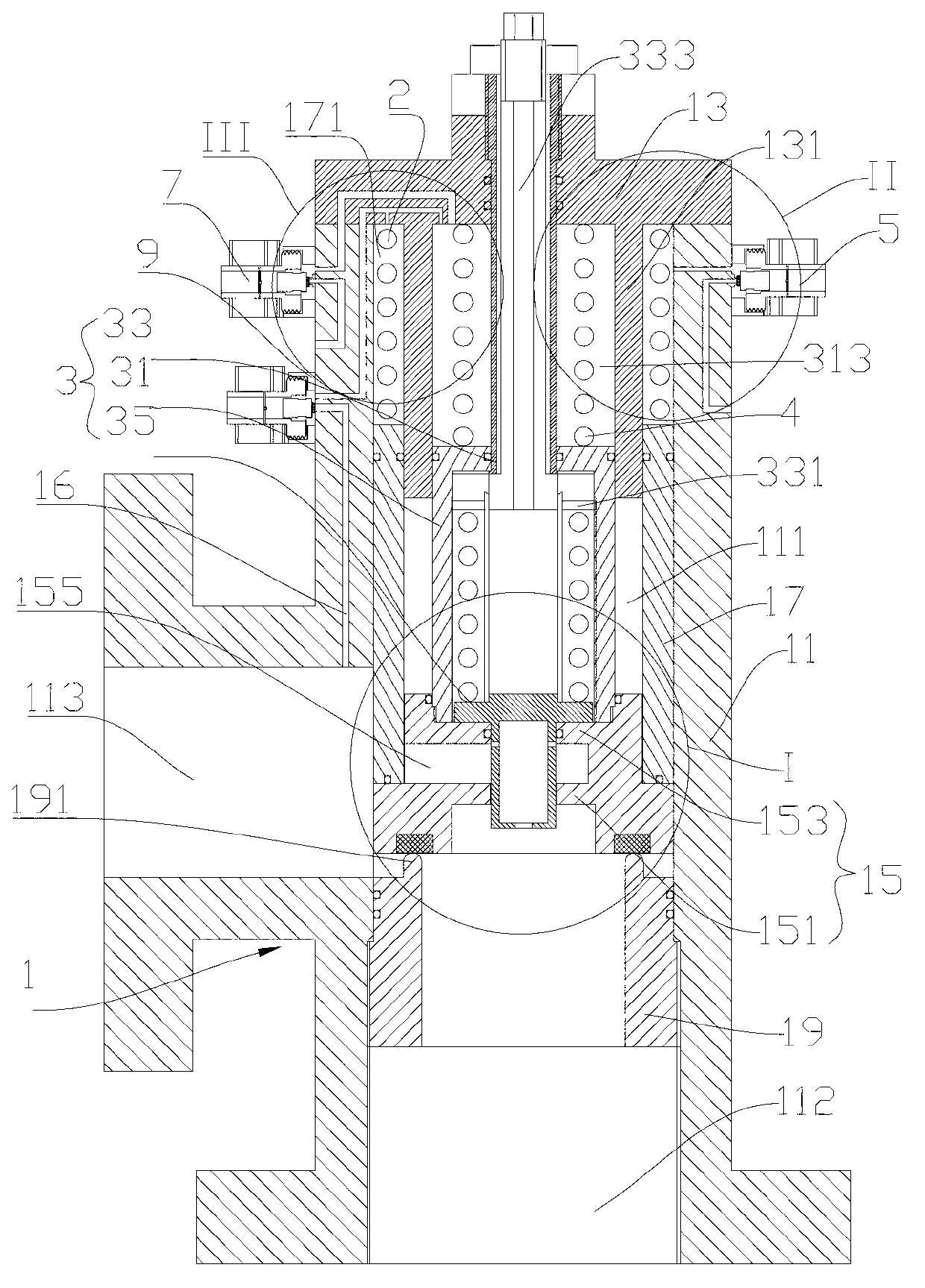

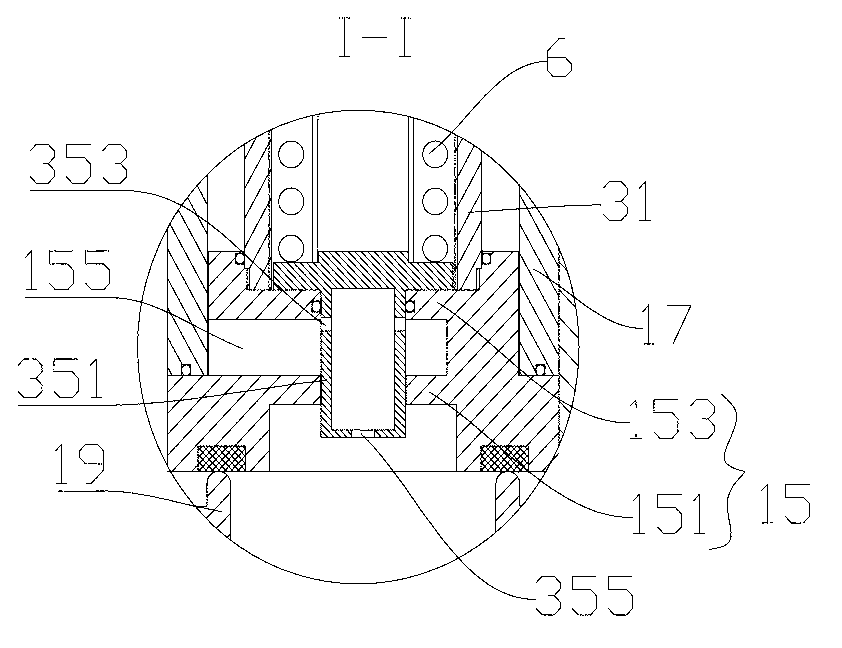

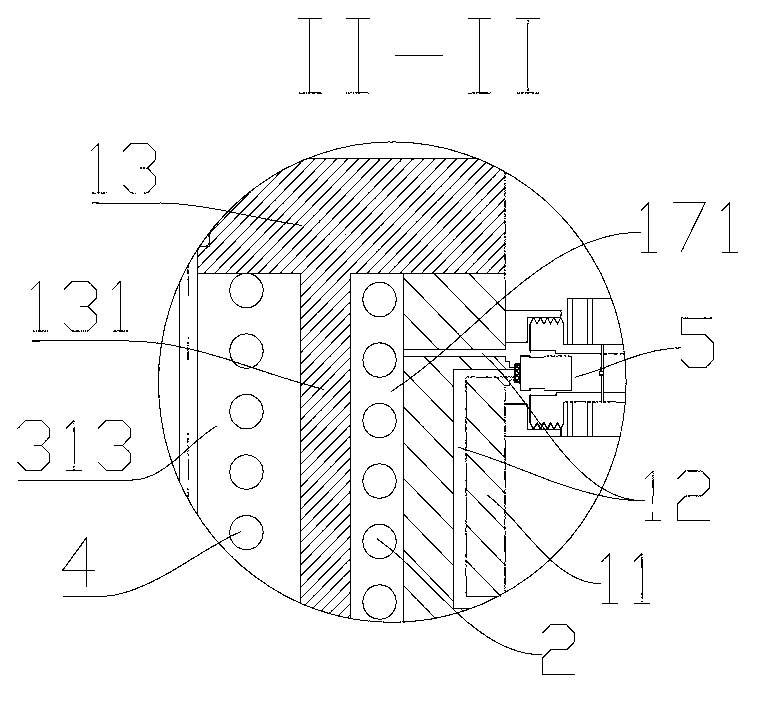

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] Please refer to figure 1 , the gas well remote high-pressure switch well device of the present invention includes a switch valve 1, a pressure reducing valve 3 installed in the switch valve 1, a control system (not shown), a first electromagnetic head 5, a second electromagnetic head 7 and a third electromagnetic head head 9. Wherein, the first electromagnetic head 5, the second electromagnetic head 7 and the third electromagnetic head 9 are all electrically connected to the control system, and the first electromagnetic head 5, the second electromagnetic head 7 and the third electromagnetic head 9 are all provided with a magnetic core ( not shown).

[0022] The on-off valve 1 comprises a valve body 11, a bonnet 13 installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com