Orientation system for horizontal drill of deep-hole drill carriage

A deep-hole drilling rig and directional system technology, applied to the automatic control system of drilling, directional drilling, drilling equipment, etc., can solve the problems of inconvenient absolute space position and posture positioning, unreliable and unusable self-service positioning system, etc., to achieve Ensure data reliability and accuracy, improve real-time performance and scalability, and facilitate portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

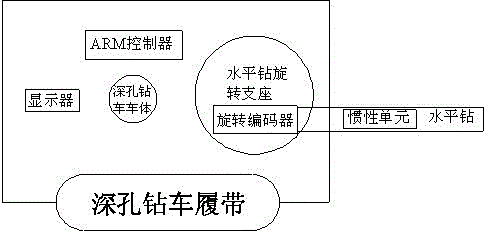

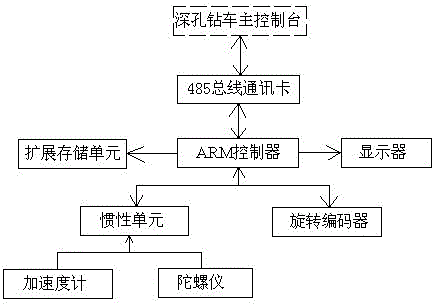

[0014] Such as figure 1 as shown, figure 1 It is a schematic diagram of the installation structure of the horizontal drilling orientation system of a deep hole drilling rig, including an inertial unit, a rotary encoder, a 485 bus communication card, an ARM controller and a display. The inertial unit, a rotary encoder, a 485 bus communication card, and an ARM controller All contain the same defined system bus interface, which are stacked and plugged together through 32 core pins. The 485 bus communication card contains a 485 bus communication interface. The inertial unit includes a UART serial bus interface and six sensors. The six Each sensor is divided into three orthogonally installed accelerometers and three orthogonally installed gyroscopes; the rotary encoder has a differential signal input interface, and the ARM controller has a switch signal input interface, a differential signal input interface, and a UART serial bus interface and display driver interface;

[0015] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com