A kind of self-cleaning rope and its making method

A production method and self-cleaning technology, applied in the field of ropes, can solve the problems of no longer beautiful appearance, affecting the use effect, easy to be stained, etc., and achieve the effect of good self-cleaning effect, prolonging the service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

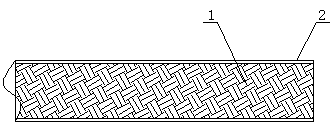

Image

Examples

Embodiment 1

[0025] 1) Mix n-tetrabutyl titanate, glacial acetic acid and deionized water with a volume ratio of 1:6:6 to prepare a titanium dioxide hydrosol;

[0026] 2) Silica hydrosol is prepared by mixing ethyl orthosilicate, glacial acetic acid and deionized water with a volume ratio of 1:5:10;

[0027] 3) The titanium dioxide hydrosol and silicon dioxide hydrosol prepared in steps 1) and 2) are prepared into titanium dioxide-silicon dioxide hydrogel according to the molar ratio of titanium to silicon 30:1;

[0028] 4) Coating and finishing the rope matrix with the prepared titania-silica hydrogel, then treating with hot water at 70°C for 30 min, and finally drying it.

Embodiment 2

[0030] 1) Mix n-tetrabutyl titanate, glacial acetic acid and deionized water with a volume ratio of 1:12:6 to prepare a titanium dioxide hydrosol;

[0031] 2) The silica hydrosol is prepared by mixing ethyl orthosilicate, glacial acetic acid and deionized water in a volume ratio of 1:5:15;

[0032] 3) The titanium dioxide hydrosol and silicon dioxide hydrosol prepared in steps 1) and 2) are prepared into titanium dioxide-silicon dioxide hydrogel according to the molar ratio of titanium to silicon 60:1;

[0033] 4) Coating and finishing the rope matrix with the prepared titania-silica hydrogel, then treating with hot water at 100°C for 5 minutes, and finally drying.

Embodiment 3

[0035] 1) Mix n-tetrabutyl titanate, glacial acetic acid and deionized water with a volume ratio of 1:10:6 to prepare a titanium dioxide hydrosol;

[0036] 2) The silica hydrosol is prepared by mixing ethyl orthosilicate, glacial acetic acid and deionized water in a volume ratio of 1:5:12;

[0037] 3) The titanium dioxide hydrosol and the silicon dioxide hydrosol prepared in steps 1) and 2) are prepared into titanium dioxide-silicon dioxide hydrogel according to the molar ratio of titanium to silicon: 40:1;

[0038] 4) Coating and finishing the rope matrix with the prepared titania-silica hydrogel, then treating with hot water at 85°C for 20 min, and finally drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com