Manual bidirectional-rolling washing machine

A washing machine and manpower technology, applied in other washing machines, washing machines with containers, washing devices, etc., can solve the problems of poor cleanability, high wear rate of clothes, large power consumption, etc., and achieve good laundry effect, energy saving, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described below.

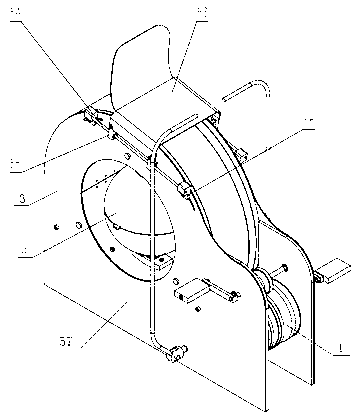

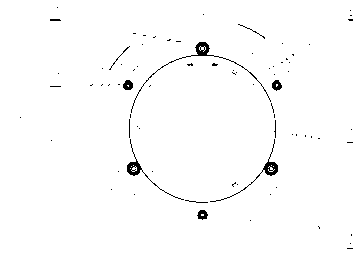

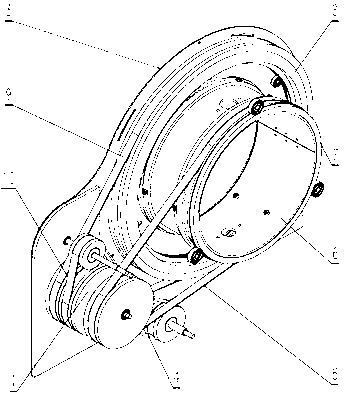

[0035] Implement a kind of manual two-way tumble washing machine provided by the present invention, this washing machine is manual washing machine, its main structure comprises human power transmission mechanism, laundry dehydration mechanism, and frame; There is a human power transmission mechanism 1; a laundry dehydration mechanism 2 is arranged in the middle of the frame side plate 57 of the frame 3; the specific structural relationship of its various parts is as follows:

[0036] The frame 3 is composed of two frame side plates 57 with transmission side plates 13 fixed to the corresponding front ends, and is a stable manpower structure formed by connecting and fixing the manpower transmission mechanism 1 and the laundry dehydration mechanism 2 arranged in the middle of the two frame side plates 57. Two-way tumbling washing machine rack; the human power transmission mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com