Environment-friendly halftone printing ink

A printing ink and halftone technology, applied in the field of environmentally friendly halftone printing inks, can solve the problems of poor halftone layer printing effect of inks, solvent contamination of packaging, and solvent is not environmentally friendly enough to meet market environmental protection and high-end exquisite. The effect of printing, good reproducibility and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

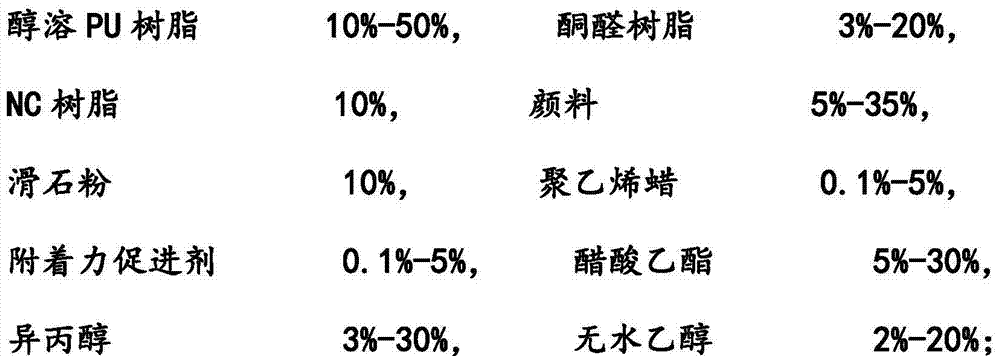

[0021] An environment-friendly halftone printing ink, prepared from the following components by weight percentage:

[0022] (1) Alcohol-soluble PU resin 10%, (2) Keto-formaldehyde resin 20%,

[0023] (3) NC resin 10%, (4) Pigment 5%,

[0024] (5) Talc powder 10%, (6) Polyethylene wax 3%,

[0025] (7) Adhesion promoter 5% (8) Ethyl acetate 5%,

[0026] (9) 30% isopropanol, (10) 2% absolute ethanol;

[0027] Its preparation method includes the following steps: put (8), (9), (10) into the kettle and start stirring, put (2) and (3) into the stirring until it dissolves into a transparent and clear liquid, and then put (1) into the stirring Mix well, then put (4), (5), (6) and (7) into stirring for 20-30 minutes, and then grind them with a sand mill to a fineness of ≤15 microns, adjust the viscosity and hue, after inspection Qualified, filter with 120 meshes, pack into finished product, and use anhydrous ethanol, isopropanol, which has little environmental pollution, as diluent ...

Embodiment 2

[0035] An environment-friendly halftone printing ink, prepared from the following components by weight percentage:

[0036] (1) Alcohol-soluble PU resin 20%, (2) Keto-formaldehyde resin 16%,

[0037] (3) NC resin 2%, (4) Pigment 20%,

[0038] (5) talcum powder 3%, (6) polyethylene wax 0.9%,

[0039] (7) Adhesion promoter 0.1%, (8) Ethyl acetate 15%,

[0040] (9) 3% isopropanol, (10) 20% absolute ethanol;

[0041] Its preparation method comprises the following steps:

[0042] Put (8), (9), (10) into the kettle and start stirring, put (2) and (3) into the kettle and stir until it dissolves into a transparent and clear liquid, then put (1) into it and stir well, then put (4) , (5), (6), (7) put into stirring for 20-30 minutes, and then grind it with a sand mill to a fineness of ≤15 microns, adjust the viscosity and hue, pass the inspection, and filter with 120 mesh , Packed into a finished product, use anhydrous ethanol, isopropanol, which is less polluting to the environmen...

Embodiment 3

[0044] An environment-friendly halftone printing ink, prepared from the following components by weight percentage:

[0045] An environment-friendly halftone printing ink, prepared from the following components by weight percentage:

[0046] (1) 50% alcohol-soluble PU resin, (2) 10% ketone-formaldehyde resin,

[0047] (3) NC resin 2%, (4) Pigment 10%,

[0048] (5) Talc powder 3%, (6) Polyethylene wax 1,

[0049] (7) Adhesion promoter 2%, (8) Ethyl acetate 10%,

[0050] (9) 3% isopropanol, (10) 9% absolute ethanol,

[0051] Its preparation method comprises the following steps:

[0052] Put (8), (9), (10) into the kettle and start stirring, put (2) and (3) into the kettle and stir until it dissolves into a transparent and clear liquid, then put (1) into it and stir well, then put (4) , (5), (6), (7) put into stirring for 20-30 minutes, and then grind it with a sand mill to a fineness of ≤15 microns, adjust the viscosity and hue, pass the inspection, and filter with 120 mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com