Method for circularly using agricultural wastes and producing organic fertilizers

A technology of agricultural waste and organic fertilizer, which is applied to the preparation of organic fertilizer, organic fertilizer, and the treatment of bio-organic parts, etc. It can solve the problems that organic fertilizer is greatly affected by climate, restricts the sustainable development of aquaculture, and takes a long time to compost. Achieve strong promotion and application value, easy mechanized operation, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

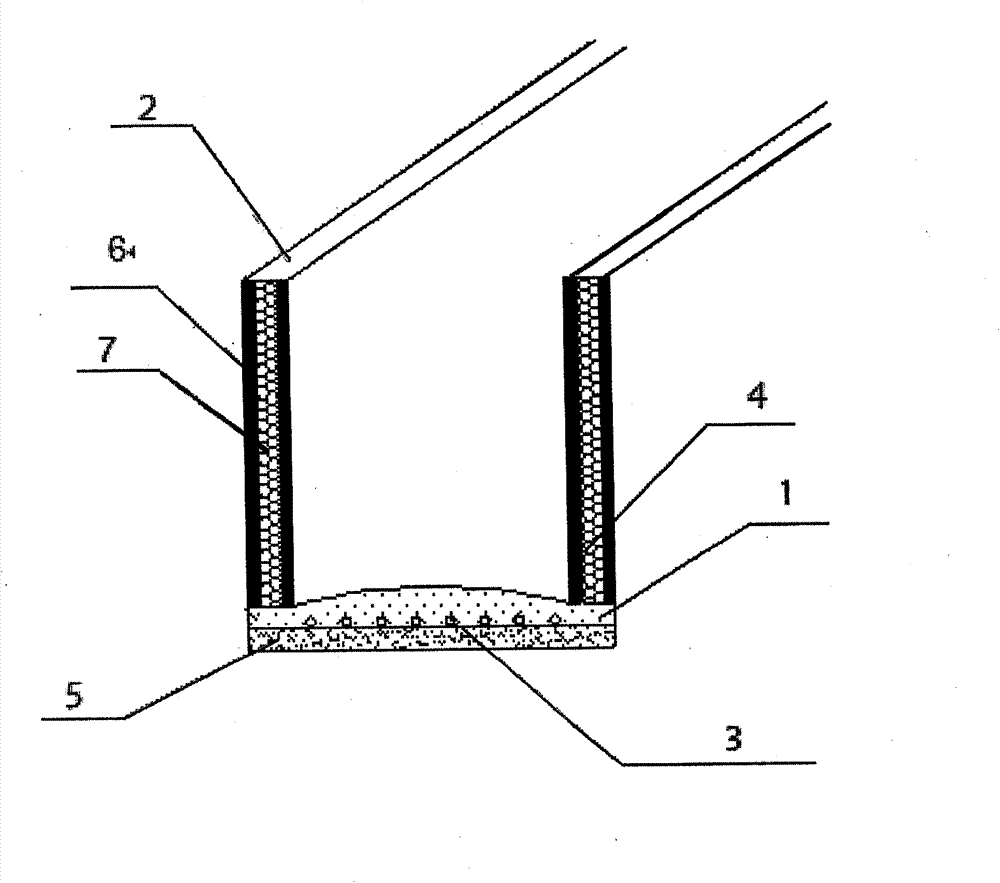

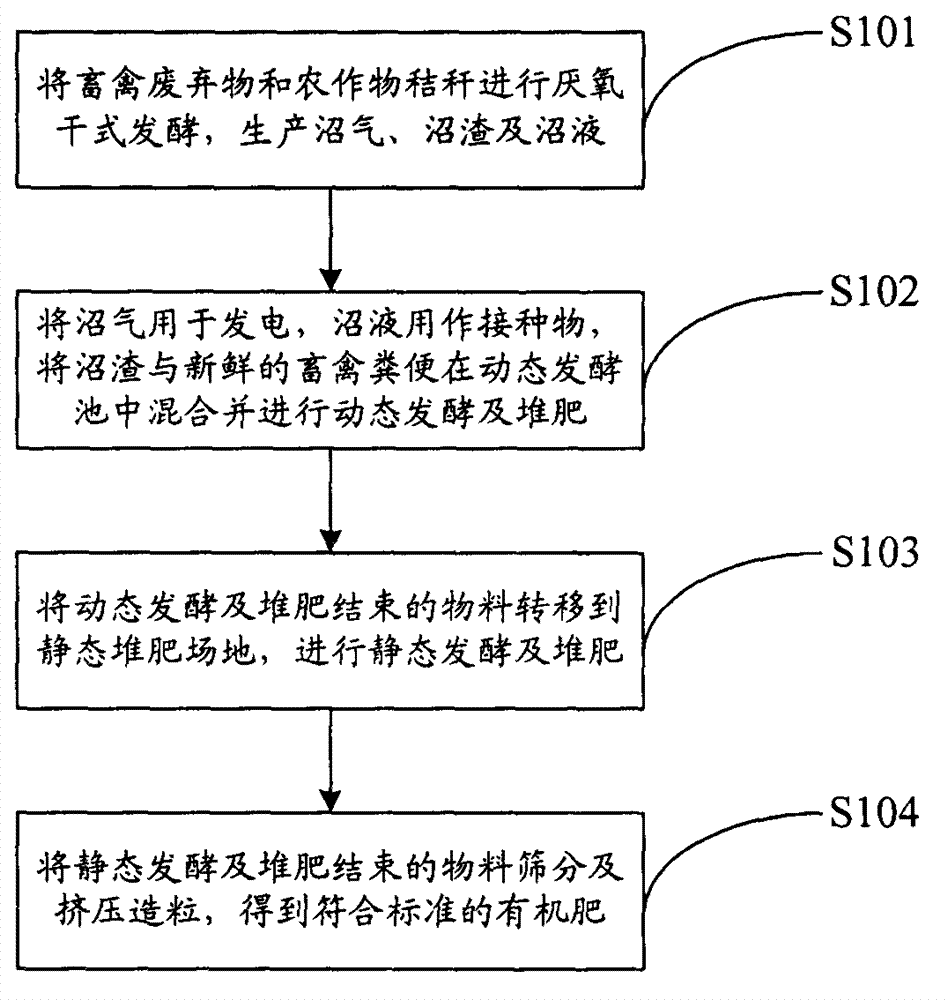

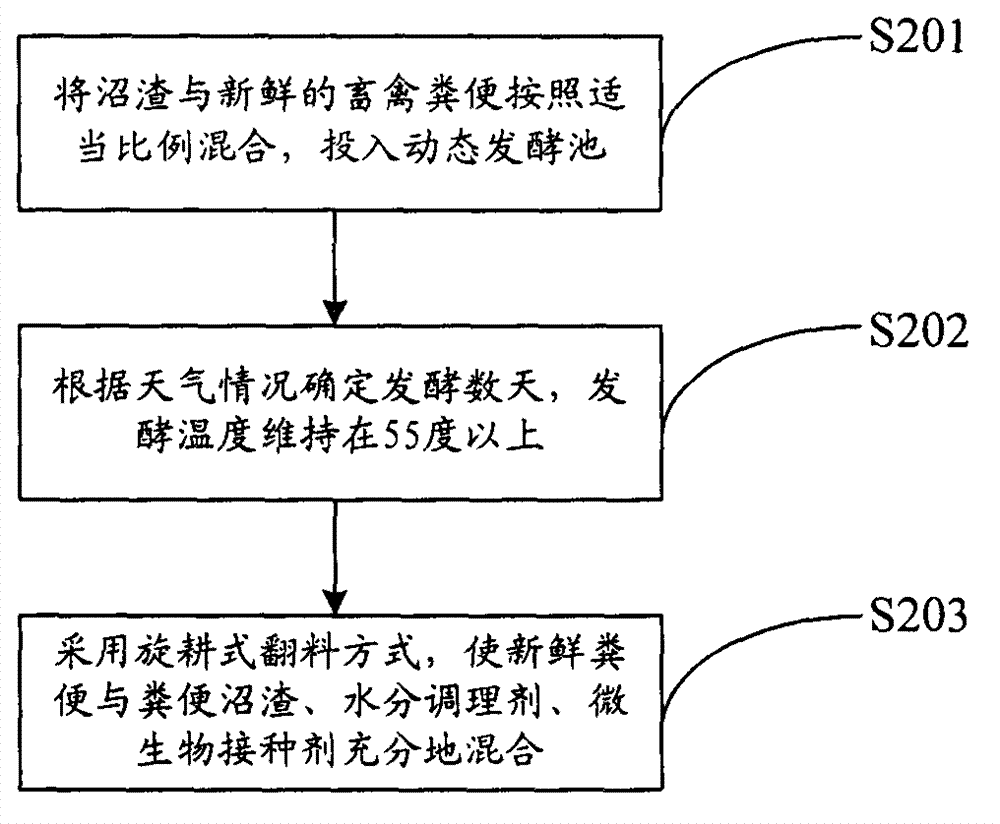

[0042] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the invention.

[0043] figure 1 The implementation flow of the method for recycling agricultural waste and producing organic fertilizer provided by the embodiment of the present invention is shown.

[0044] The method includes the following steps:

[0045] In step S101, anaerobic dry fermentation is performed on livestock and poultry waste and crop stalks to produce biogas, biogas residue and biogas slurry;

[0046] In step S102, the biogas is used for power generation, the biogas slurry is used as an inoculum, and the biogas residue is mixed with fresh livestock and poultry manure in a dynamic fermentation tank for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com