Motorcycle tire

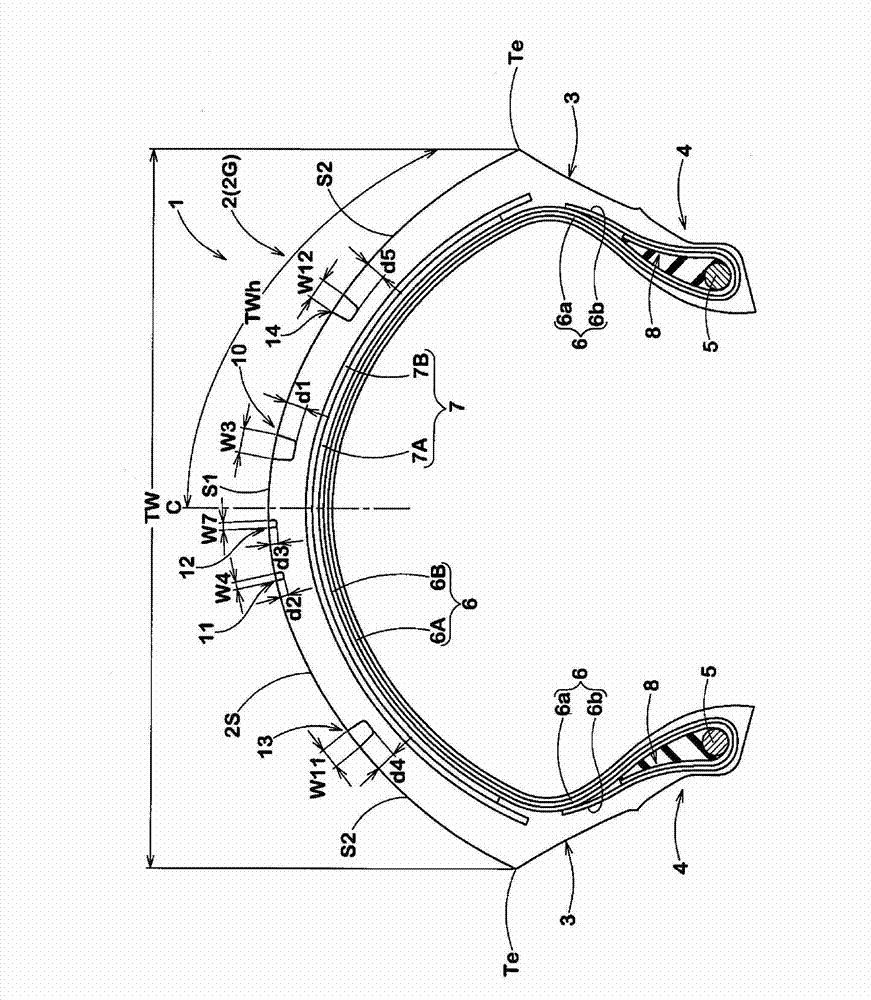

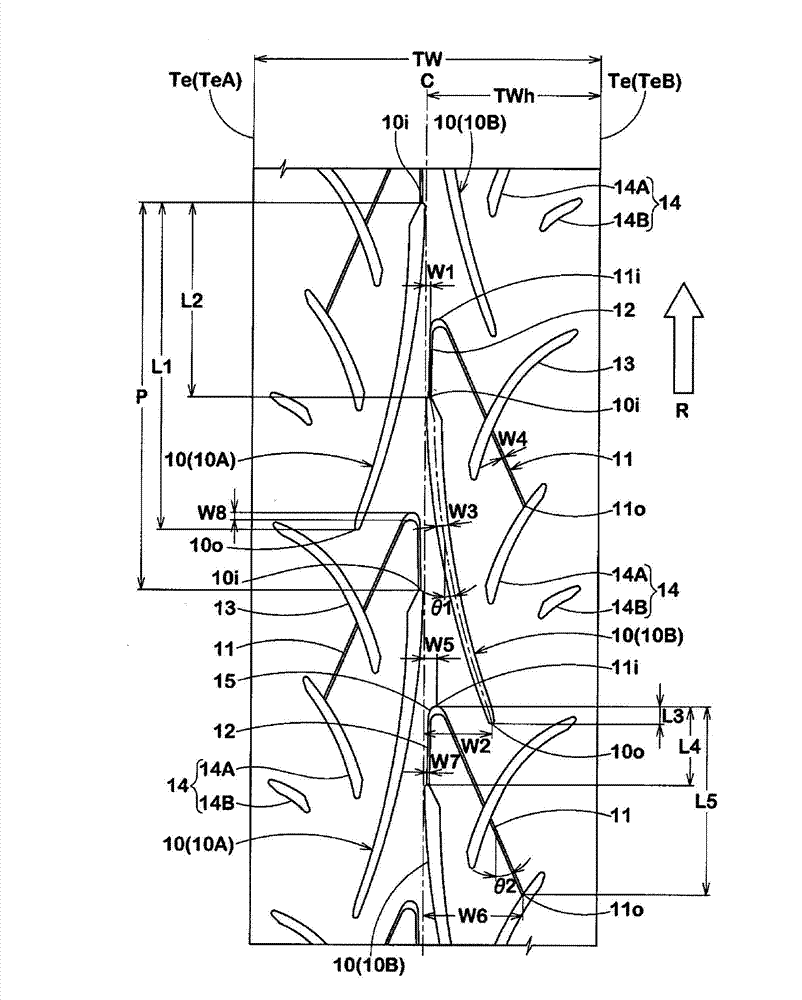

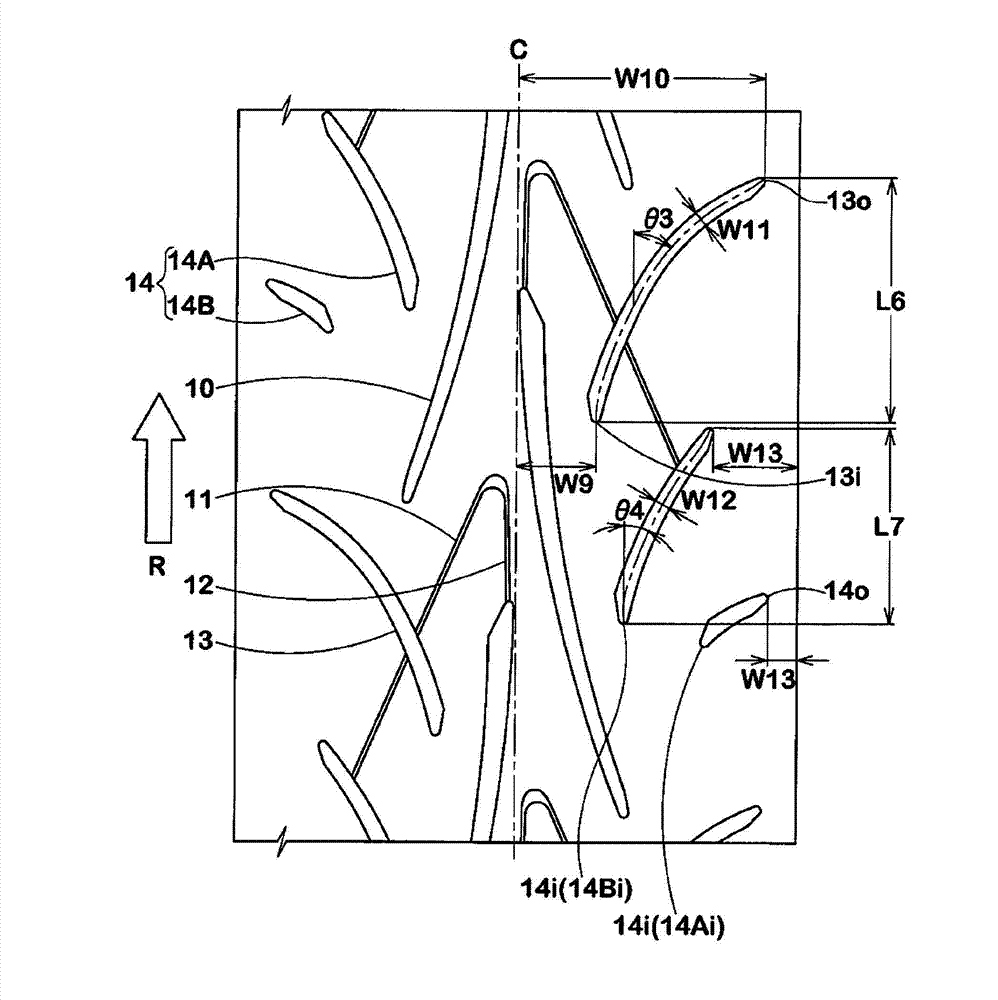

一种摩托车、轮胎的技术,应用在摩托车轮胎、摩托车、轮胎零部件等方向,能够解决侧抗力降低、过渡特性变差、转弯性能降低等问题,达到抑制热熔融、保持寿命、提高散热性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] Manufacturing has figure 1 The basic structure of the rear tires for motorcycles based on the specifications in Table 1, and their performance was tested. In addition, for comparison, the same test was performed on a commercially available tire having the same basic structure as a conventional example. Among them, the common specifications are as follows.

[0080] Tire size:

[0081] Front wheel: 120 / 70ZR17

[0082] Rear wheel: 180 / 55ZR17

[0083] Rim size:

[0084] Front wheel: 17×MT3.50

[0085] Rear wheel: 17×MT5.50

[0086] Internal pressure:

[0087] Front wheel: 250kPa

[0088] Rear wheel: 290kPa

[0089] The test method is as follows.

[0090]

[0091] The test tire is mounted on the rear wheel of a motorcycle with a displacement of 600cc, and a test run is carried out on a circuit with a lap length of 3700m. By testing the driver's senses, the "tire life", "heat fusion performance", comfort", "initial cornering pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com