Top Roller Clamping Device

A clamping device and top roller technology, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of low work efficiency and high labor intensity of manual loading and unloading of top rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

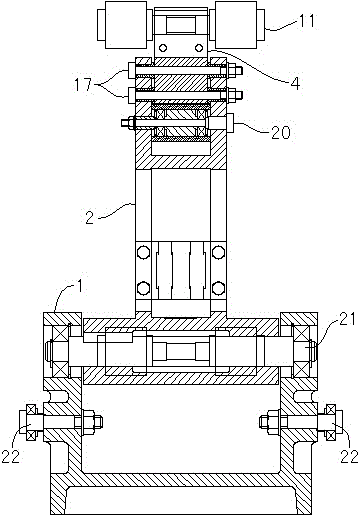

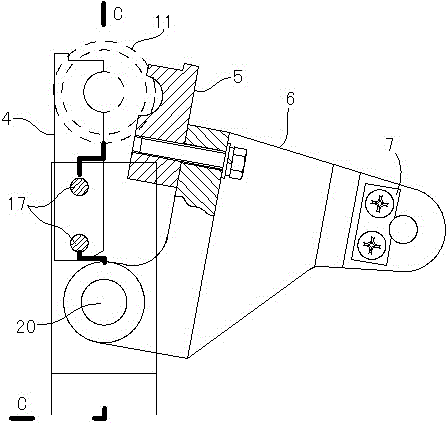

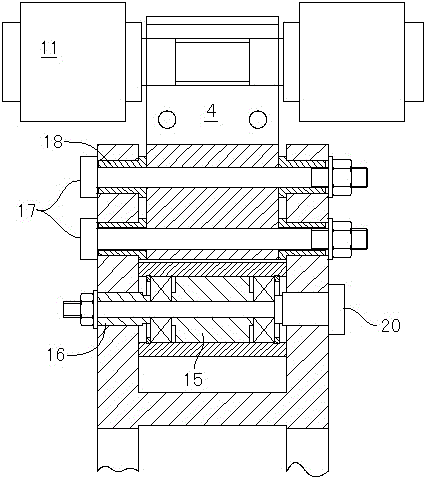

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0026] refer to image 3 , Figure 4 As shown, the static jaw 4 is installed on the tong frame 2 with two static jaw pin shafts 17 and axle sleeves 18, and the static jaw pin shaft 17 is fastened on the tong frame 2 by nuts; Fastened on the rocker 6, the rocker 6 is installed on the clamp frame 2 through the bushing 15, the bearing spacer 16, the rocker shaft 20 and the miniature bearing.

[0027] When the piston rod of the rocker cylinder 25 is withdrawn, the opening angle A between the static jaw 4 and the moving jaw 5 is greater than 10°30′.

[0028] The clamp frame cylinder 26 is connected with the clamp frame 2 through the joint bearing 14, and the rocking block cylinder 25 is connected with the described rocking block 6 through another joint bearing 14; the piston rod of the clamp frame cylinder 26, the rocking block cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com