Rapid workpiece clamping mechanism for lathe

A clamping mechanism and workpiece technology, applied in metal processing machinery parts, clamping, manufacturing tools, etc., can solve the problems of large centrifugal force, large operating force, and many parts and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

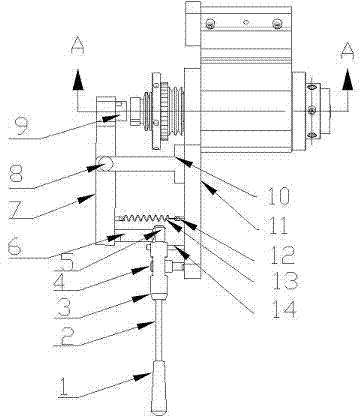

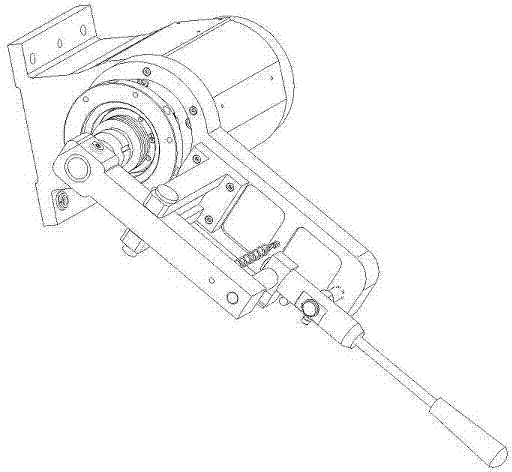

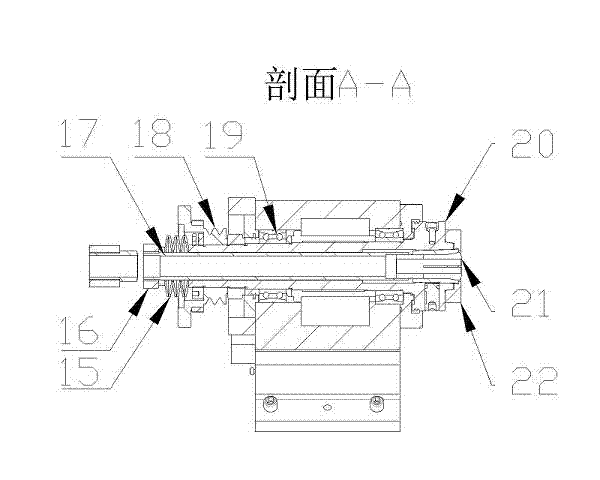

[0015] Such as figure 1 , 2 , 3, the present invention is composed of the following mechanisms: operating mechanism (handle cover 1, handle bar 2, rotating shaft 3), positioning mechanism (positioning shaft 4, support frame 10, support plate 11, pull shaft 12, extension spring 13. Locating pin 14), sliding mechanism (slope block 5), linkage mechanism (guide shaft 6, connecting rod 7, positioning shaft 2 8, top block 9), tensioning mechanism (butterfly spring 15, adjusting nut 16, Pull rod 17), clamping mechanism (collet collet 21, gland 22), rotating mechanism (belt pulley 18, main shaft bearing 19, main shaft 20).

[0016] When the handle bar 2 is in the horizontal position, there is a gap of 2-3mm between the top block 9 and the adjusting nut 16. Due to the elastic deformation force of the belleville spring, the pull bar tightens the collet, and the workpiece is in a clamped state.

[0017] When the handle bar 2 is swung downward, the rotating shaft 3 will rotate on the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com