Automatic aluminum liquid dispensing device used for aluminum ingot on continuous castcontinuous casting production line for aluminum ingots

A casting production line and automatic distribution technology, applied in the field of large-tonnage aluminum ingot continuous casting production line, can solve the problems of asynchronous moving speed, low aluminum ingot quality and yield, low aluminum liquid distribution accuracy, etc., to ensure quality and yield. , Improve the distribution accuracy, improve the quality and yield of aluminum ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

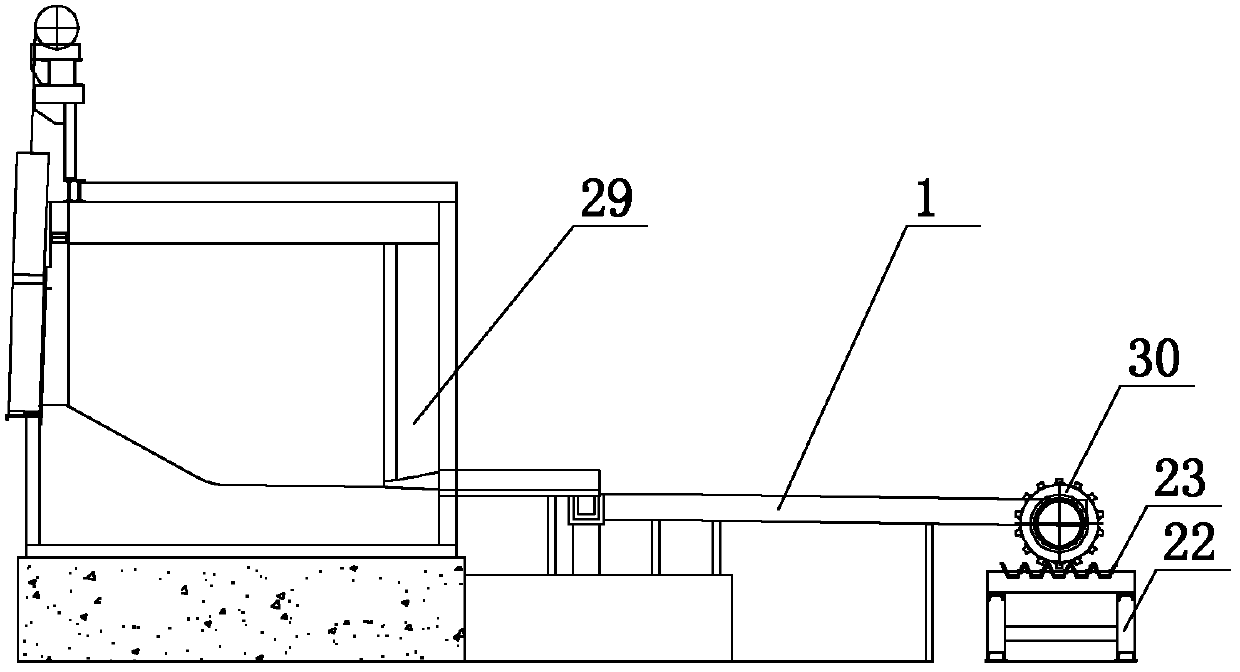

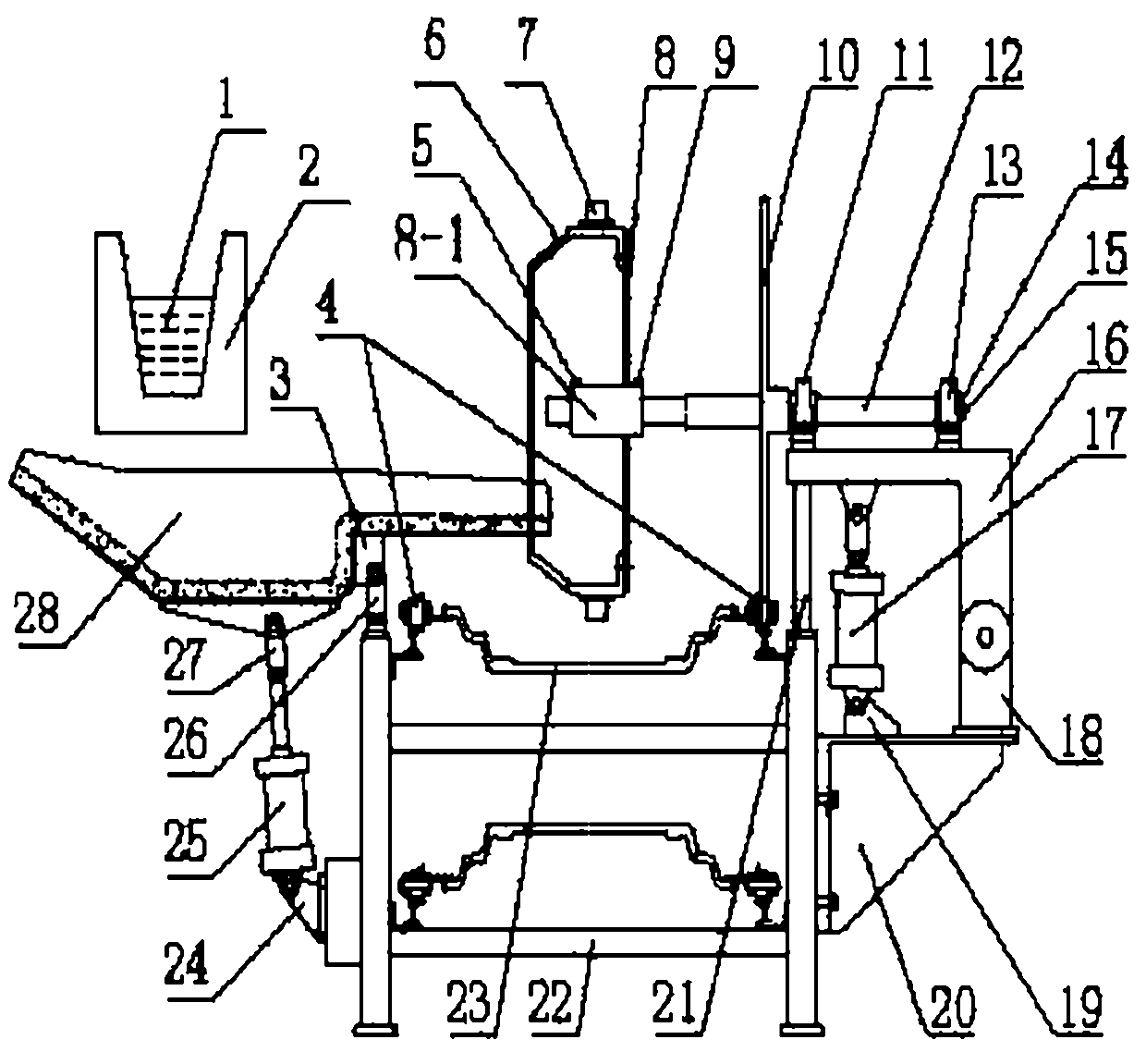

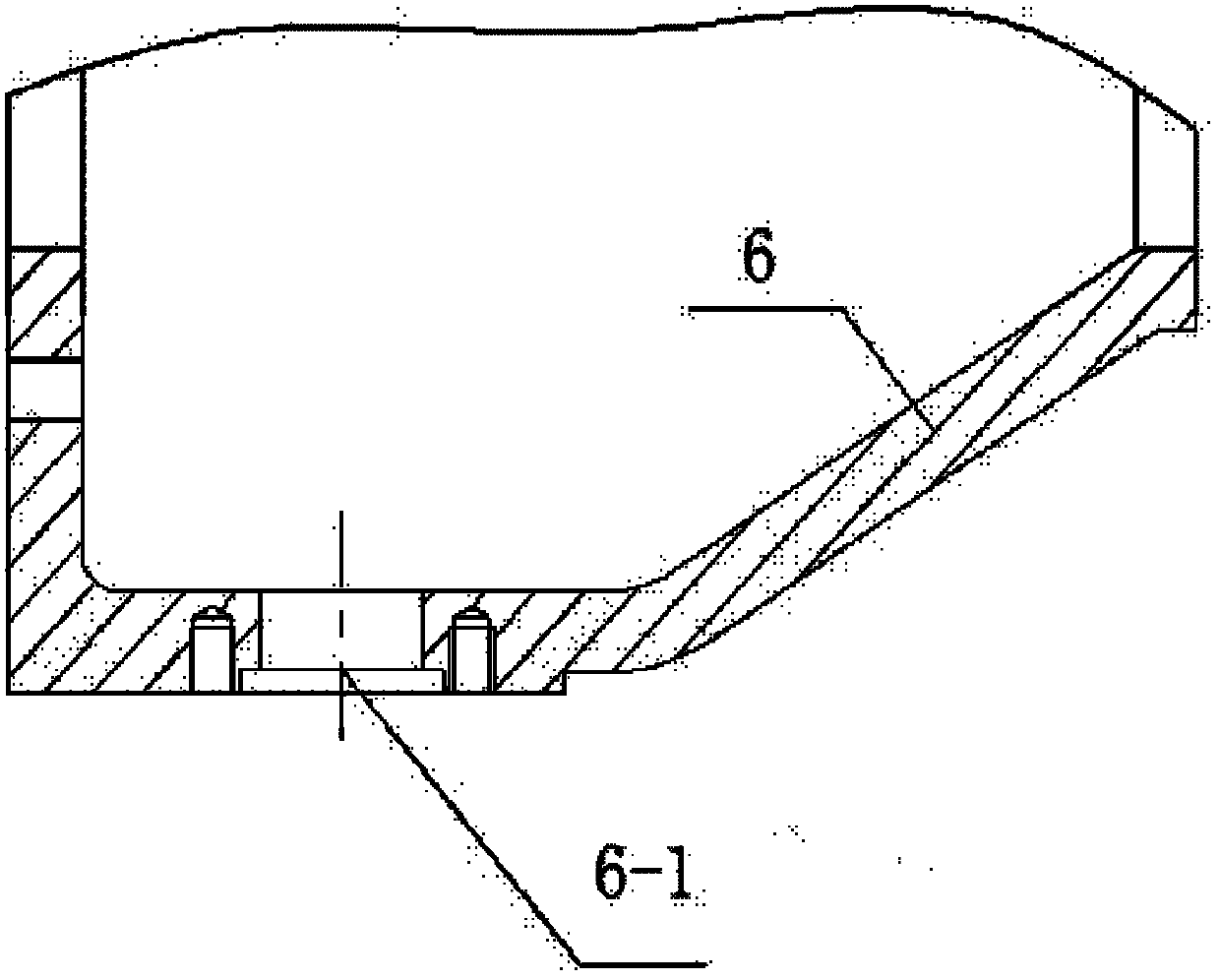

[0009] The present invention is an automatic distributing device for molten aluminum used in an aluminum ingot continuous casting production line, such as figure 1 , figure 2 , image 3 As shown, the first support 20 is fixed on the right side of the casting machine frame 22 by a bolt group, the second support 18 and the third support 19 are fixed on the first support 20 by a bolt group, and the first cylinder 17 The tailstock is hinged with the third support 19, the end of the piston rod of the first cylinder 17 is hinged with the bottom of the first support 16, the first support 16 and the second support 18 are hinged, and are used to support the second support of the first support 16 21 is fixed on the top of casting machine frame 22;

[0010] The bottom of the boat-shaped ladle 28 is hinged with the connector 27 of the second cylinder 25, the tailstock of the second cylinder 25 is hinged with the fourth support 24, and the fourth support 24 is installed on the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com