Technology for processing blank of paper shredding blade and processing device of technology

A technology of processing technology and processing equipment, which is applied in the field of processing technology and processing equipment for processing shredded paper blade blanks, can solve the problems of high cost, poor strength and easy deformation of shredded paper blades, and achieve strong cutting strength and convenient processing , the effect of enhancing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

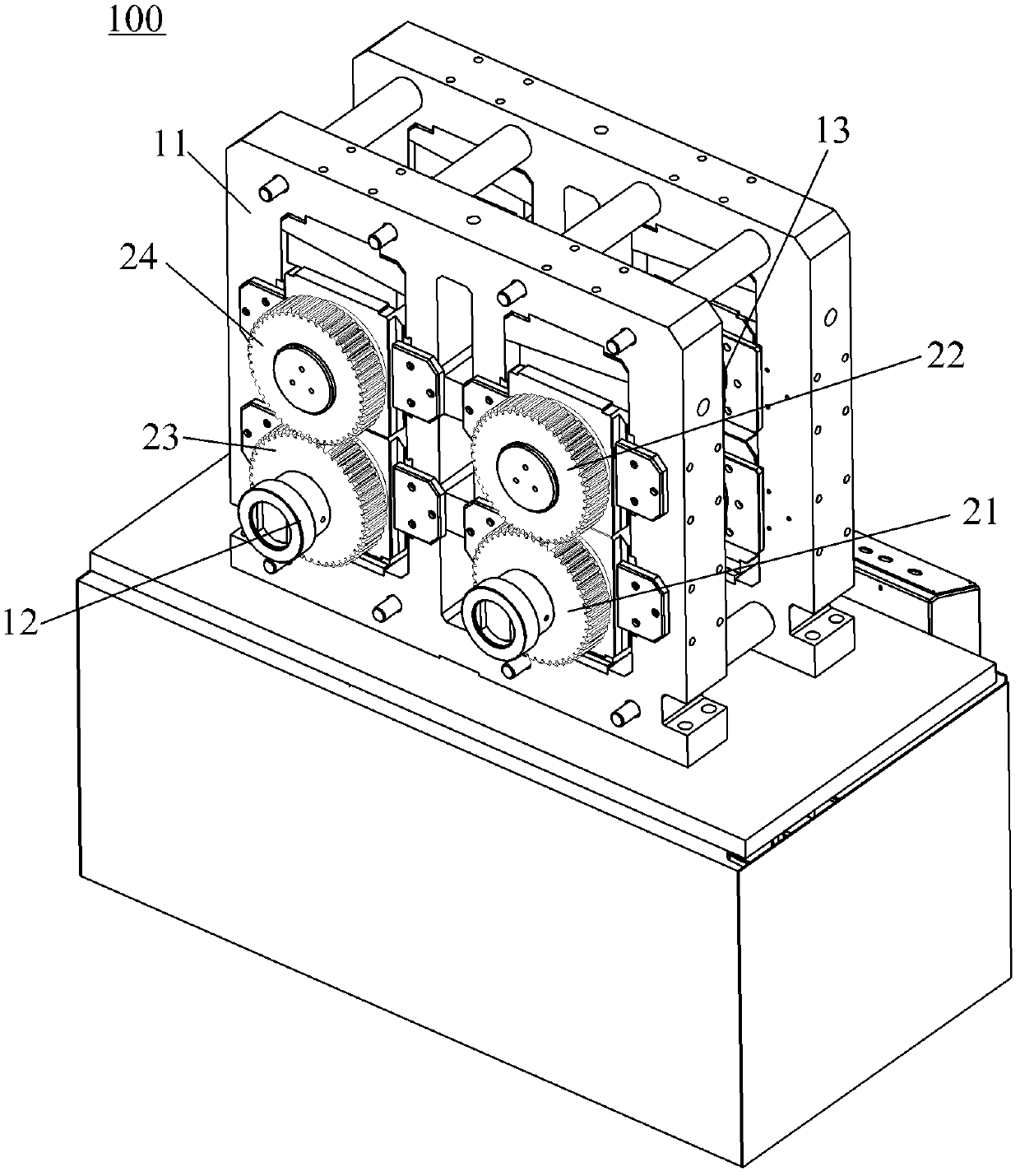

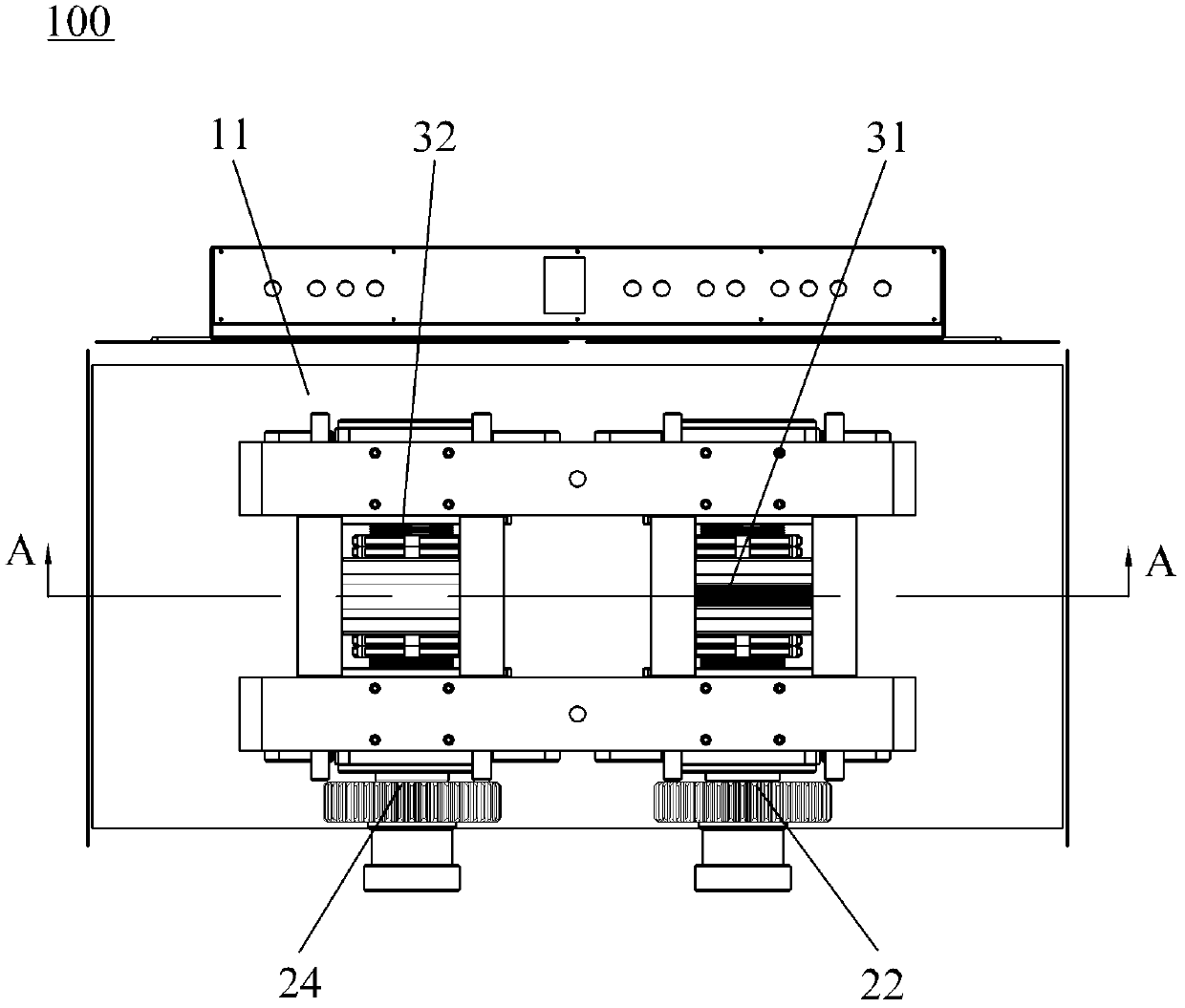

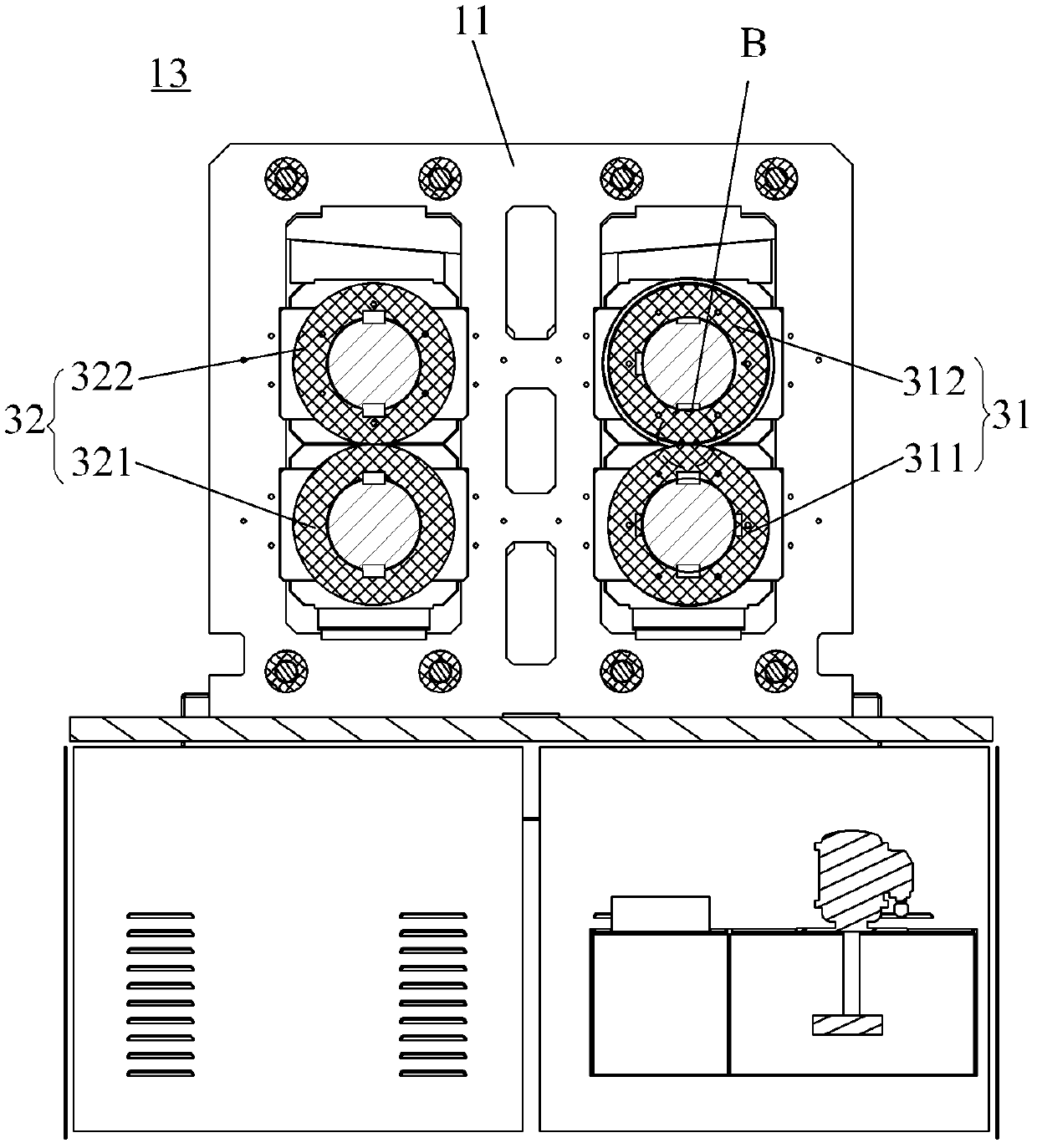

[0029] refer to Figure 1 to Figure 6 , the present invention discloses a shredding blade stock processing equipment 100, which is used to process a metal strip into a strip-shaped stock 101 of a shredding blade. The shredding blade stock processing equipment 100 includes a frame 11, installed on The driving mechanism 12 on the frame 11 and the rolling mechanism 13 connected with the driving mechanism 12, the rolling mechanism 13 includes a first rolling unit 31, and the first rolling unit 31 includes a first rolling unit 31. Rolling wheel 311 and the second rolling wheel 312, the outer surface of described first rolling wheel 311 is smooth, and the outer surface of described second rolling wheel 312 is convexly provided with several protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com