Device for sterilizing medical pipe joint

A pipe joint and disinfectant technology, applied in the medical field, can solve the problems of unintentional touch and overturn of utensils, increase the risk of infection, and easy to touch the bottle mouth of utensils, so as to prevent pollution and other influences, and avoid unintentional touch and knock. Turn over, avoid the effect of touching the pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example approach

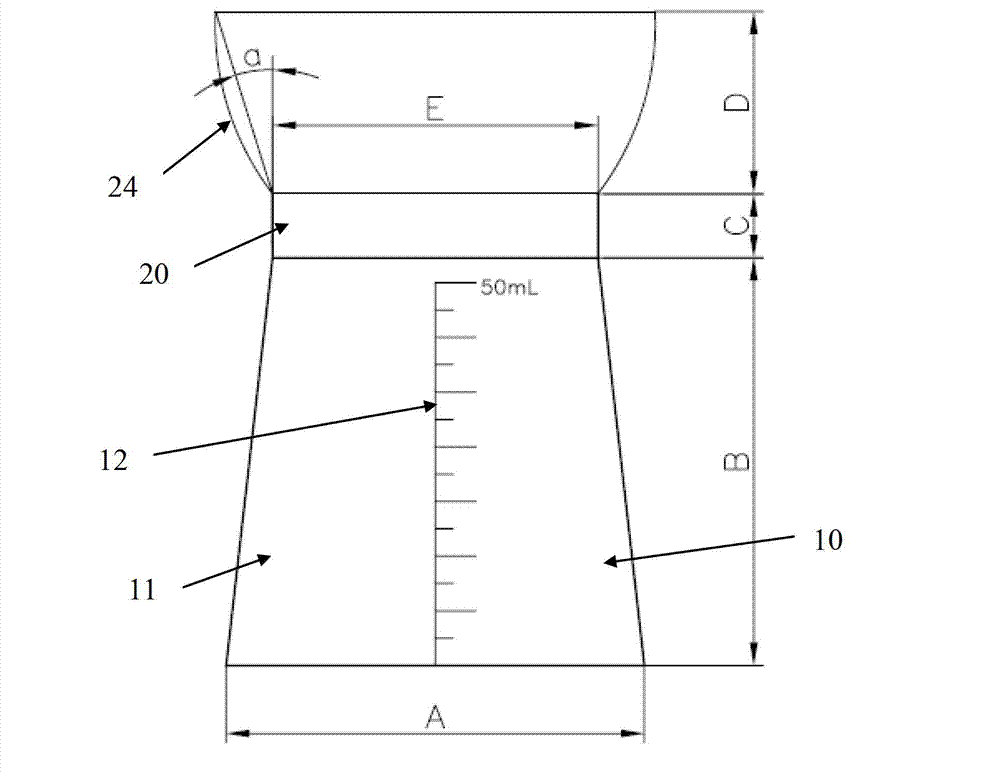

[0039] attached figure 1 It is the front view of the device for disinfecting the titanium joint of the peritoneal dialysis tube under the mode of the first embodiment of the present invention;

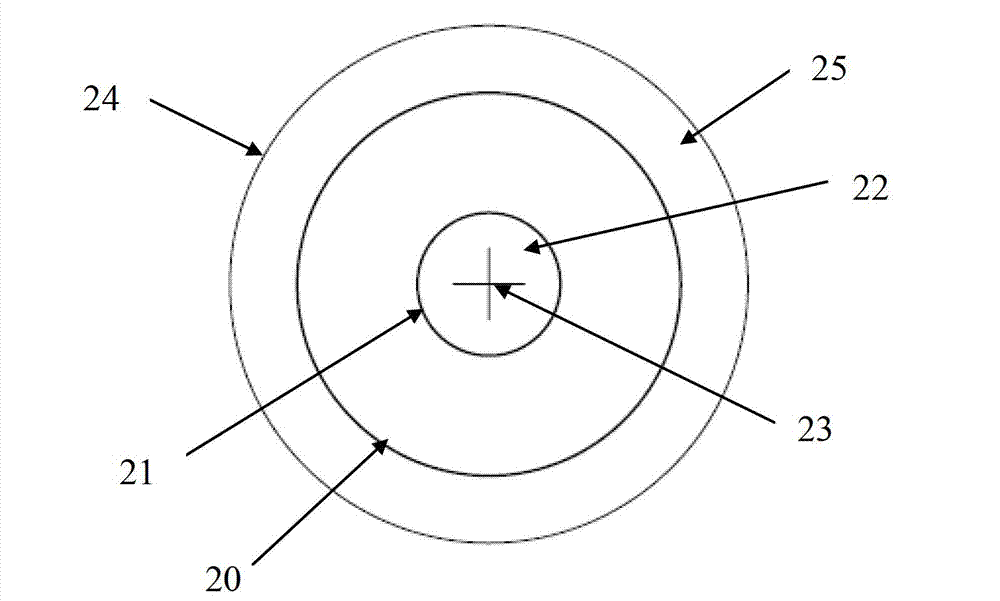

[0040] attached figure 2 It is a top view of the device for disinfecting titanium joints of peritoneal dialysis tubes under the mode of the first embodiment of the present invention;

[0041] An embodiment of the present invention provides a device for disinfection of medical pipe joints, the medical pipe joints are connected to medical pipes, including:

[0042] The bottle body is used to hold the disinfectant;

[0043] The bottle cap can be sealed and connected to the upper end of the bottle body;

[0044] The bottle cap is provided with holes for inserting and extracting medical pipe joints; wherein,

[0045] The diameter of the hole corresponds to the diameter of the medical pipe joint;

[0046] The pores are covered with elastic silicone membrane;

[0047] The device provid...

no. 2 example approach

[0088] See also figure 1 with figure 2 The device for disinfecting the titanium joint of the peritoneal tube under the shown first embodiment, the difference between the second embodiment and the first embodiment is only:

[0089] The bottle height B is 38mm, the bottom diameter A is 43mm, and the neck height C is 5mm;

[0090] The height of the bottle cap is basically consistent with the height C of the bottle neck, and the diameter E of the bottle cap is 33mm;

[0091] The diameter of the hole is 11mm;

[0092] The diameter of the hidden guide opening is 2mm;

[0093] The cover edge 24 is in the shape of an umbrella, and the angle α between the cover edge 24 and the axial direction of the bottle cap 20 is about 14°;

[0094] The height D of the cover edge is 18mm;

[0095] The total height of the container means is about 61mm.

[0096] All the other structures and disinfection processes are the same as those in the first embodiment.

no. 3 example approach

[0098] See also figure 1 with figure 2 The device for disinfecting the titanium joint of the peritoneal tube under the shown first embodiment, the difference between the third embodiment and the first embodiment is only:

[0099] The bottle height B is 40mm, the bottom diameter A is 44mm, and the neck height C is 4mm;

[0100] The height of the bottle cap corresponds basically to the height C of the bottle neck, and the diameter E of the bottle cap is 35mm;

[0101] The diameter of the hole is 12.5mm;

[0102] The diameter of the hidden guide opening is 4mm;

[0103] The cover edge 24 is in an umbrella shape, and the angle α between the cover edge 24 and the axial direction of the bottle cap 20 is about 14.5°;

[0104] The height D of the cover edge is 20.5mm;

[0105] The total height of the container means is about 64.5mm.

[0106] All the other structures and disinfection processes are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com