Steam fryer

A gas and fryer technology, which is applied in food science and other fields, can solve the problems of inability to achieve the frying effect, uneven heating of food to be processed, and waste of heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

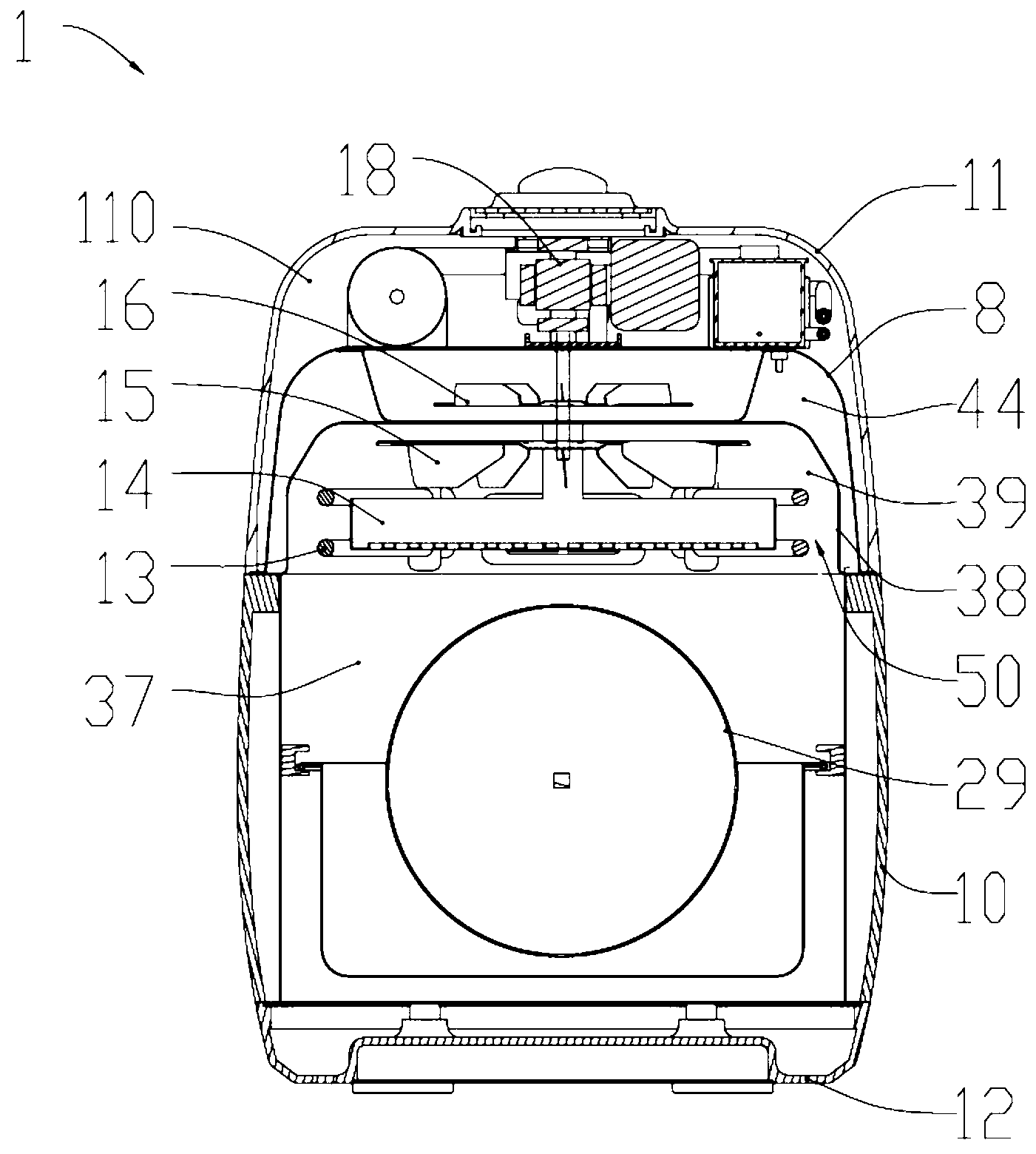

[0052] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, a gas fryer includes a main body 1 and a timer 17 and a thermostat 19 arranged on the main body 1. The main body 1 includes an upper wall 11 and a base 12 and is arranged on the upper wall. 11 and the base 12 transition side wall body 10 , and the main body 1 also has an accommodation space 110 . An upper reflector 38 is arranged on the top of the accommodation space 110, and the upper reflection plate 38 is pot-shaped and has a first basin inner space 39 on the inside; The rear reflection plate 25 on the inner side of the side wall body 10 . The opening 101 of the accommodating space 110 is located on the right side of the main body 1 , and a side cover 21 is fitted on the opening 101 . Such as Figure 5 As shown, the side cover 21 has a semi-circular shape and a front reflector 20 is arranged on the inner side; a pot-shaped baking pan 36 having a second pot inner space 43 is connected to the inner si...

Embodiment 2

[0064] The difference from the solution described in Embodiment 1 is that the atomization generator is an ultrasonic atomization generator 80 . Such as Figure 12 Shown is a schematic cross-sectional structure diagram of the ultrasonic atomization generator 80 . The ultrasonic atomization generator 80 includes an accommodating cavity capable of accommodating the atomized liquid, the accommodating cavity is composed of a lower water container 81 and a cover 86 covering the water container 81, The cover body 86 is provided with the mist guide tube 85 , and the mist guide tube 85 leads to the thermal space 37 . The inner bottom of the water container 81 is provided with an atomizer 82 and a water inlet (not shown in the figure).

[0065] A mist guiding chamber wall 88 that communicates with the mist guiding pipe 85 and extends toward the bottom of the water container 81 is fixedly connected to the cover 86. The mist guiding chamber wall 88 and the corresponding mist The carbur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com