Preparation method of fried instant noodle with good brittleness and good brittleness keeping performance

A technology of instant noodles and brittleness, applied in food preparation, application, food science, etc., can solve the texture characteristics of fried instant noodles, but there are few studies, no impact and function of fried instant noodles, no research focus of fried instant noodles, etc. problem, to achieve the effect of improving brittleness, improving taste and improving brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: Preparation of Fried Instant Noodles with Excellent Brittleness and Brittleness

[0052] See attached figure 1 , the concrete preparation method steps of fried instant noodles excellent in brittleness and brittleness are as follows:

[0053] (1) Kneading and maturing: first measure the composition of the flour according to the national standard, and according to the uniform design experiment, the amount of fat added to the raw materials is 0-1.1%, the amount of eggs added is 0.6%-2.8%, and the amount of salt added is 1 %-3%, the moisture content is 45%-56%; according to the single factor experiment, the salt content is 1.8%; the moisture content is 47%-53%; the response surface experiment, the salt content is 1.8%; the moisture content is 45%- 55%; mix the above ingredients, knead the noodles for 10 minutes, and then put them in a constant temperature culture at 25°C to proof for 15 minutes;

[0054] (2) Calendering and cutting: process the matured loose do...

Embodiment 2

[0059] Example 2: Preparation of Fried Instant Noodles Excellent in Brittleness and Brittleness

[0060] See attached figure 1 , the concrete preparation method steps of fried instant noodles excellent in brittleness and brittleness are as follows:

[0061] (1) Dough mixing and aging: according to the prior art, first determine the composition of the flour according to the national standard, and control the content of fat, eggs, salt, and moisture added in the raw materials according to the uniform design experiment; then do the single factor experiment to determine the above formula; finally The final formula of the above raw ingredients was obtained through the response surface experiment. The moisture content was 45%-55%, and the salt content was 1.8%. The above raw materials were mixed, kneaded for 10 minutes, and then placed in a constant temperature culture at 25°C for 15 minutes. .

[0062] (2) Calendering and strip cutting: process the matured loose dough into noodle s...

Embodiment 3

[0074] Embodiment three: Texture determination method

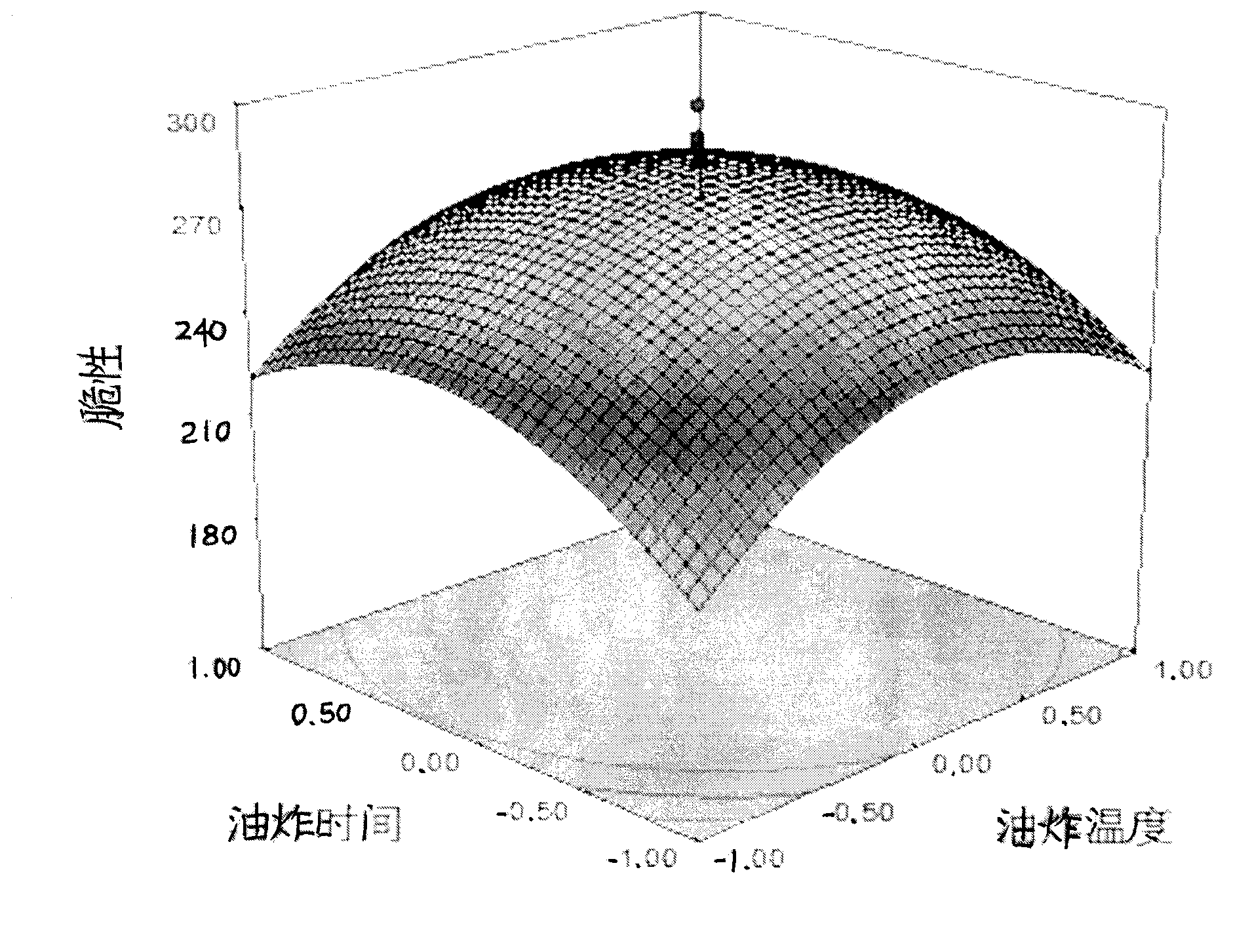

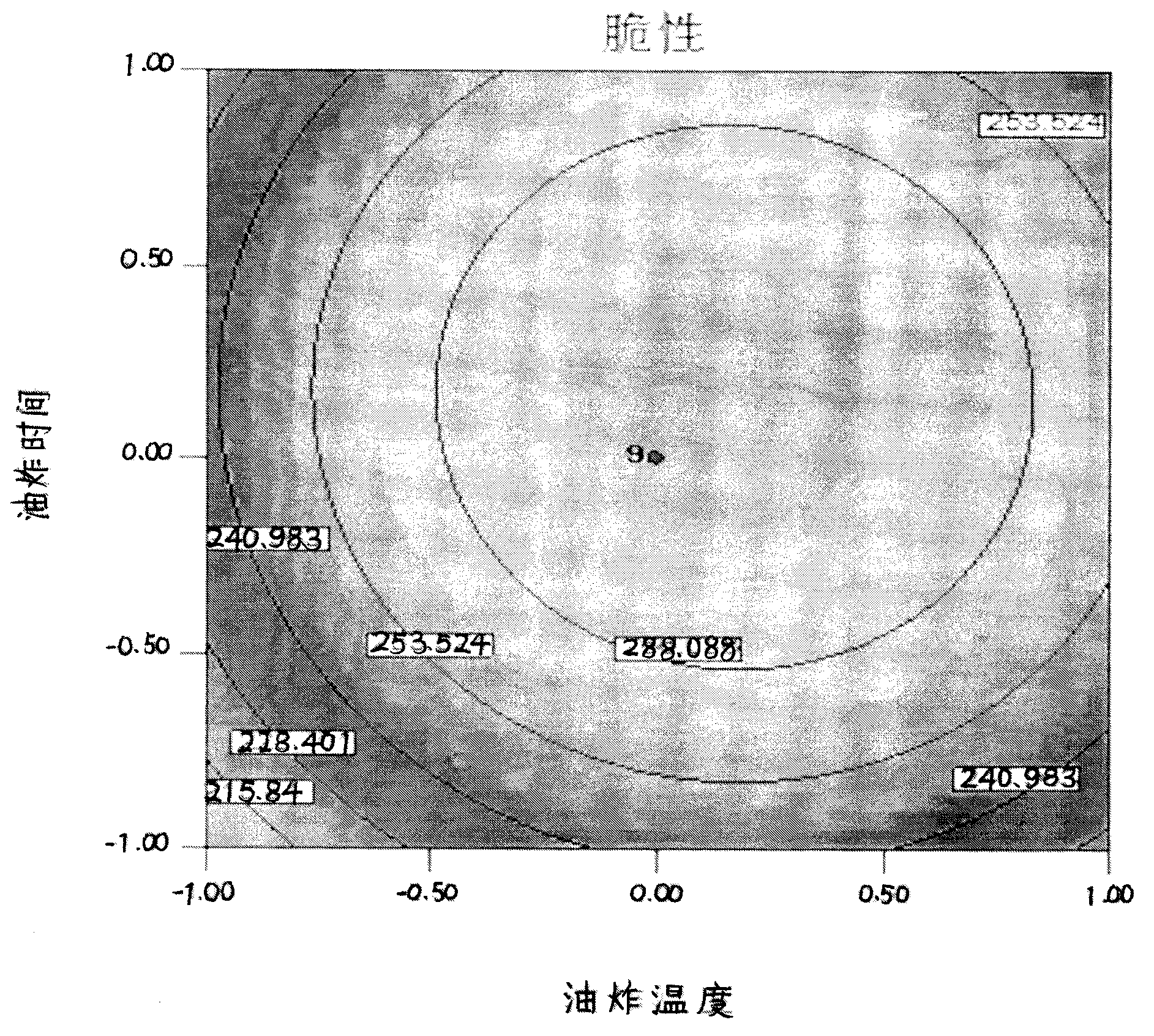

[0075] The single factor experiment measures brittleness, brittleness retention, WAI, WSI, bulk density, solid density, and expansion degree, and the uniform design experiment and response surface experiment measure brittleness and brittleness retention.

[0076] The brittleness is measured by CT3 texture analyzer, the distance is 1mm, the trigger point is 5g, the forward speed is 1.1mm / s, and the breaking peak is brittleness.

[0077] Determination of brittleness Take 5g of the sample, put it into 100ml of water at room temperature, take it out after three minutes to measure its brittleness, and use the maximum crushing stress to represent the value of brittleness.

[0078] The WAI measurement indicates the mass of the colloid obtained after each gram of sample is dissolved in water and centrifuged, representing the hydrophilicity of the sample. The specific steps are: take 2.5g of the ground sample, add 30ml of distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com