Canned sea cucumber porridge and production method thereof

A technology of canned food and sea cucumber, applied in the field of food science, can solve the problems that the dissolved nutrients cannot be retained and cannot be fully absorbed by the human body, and achieve the effects of rich taste, short soaking time, and no loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

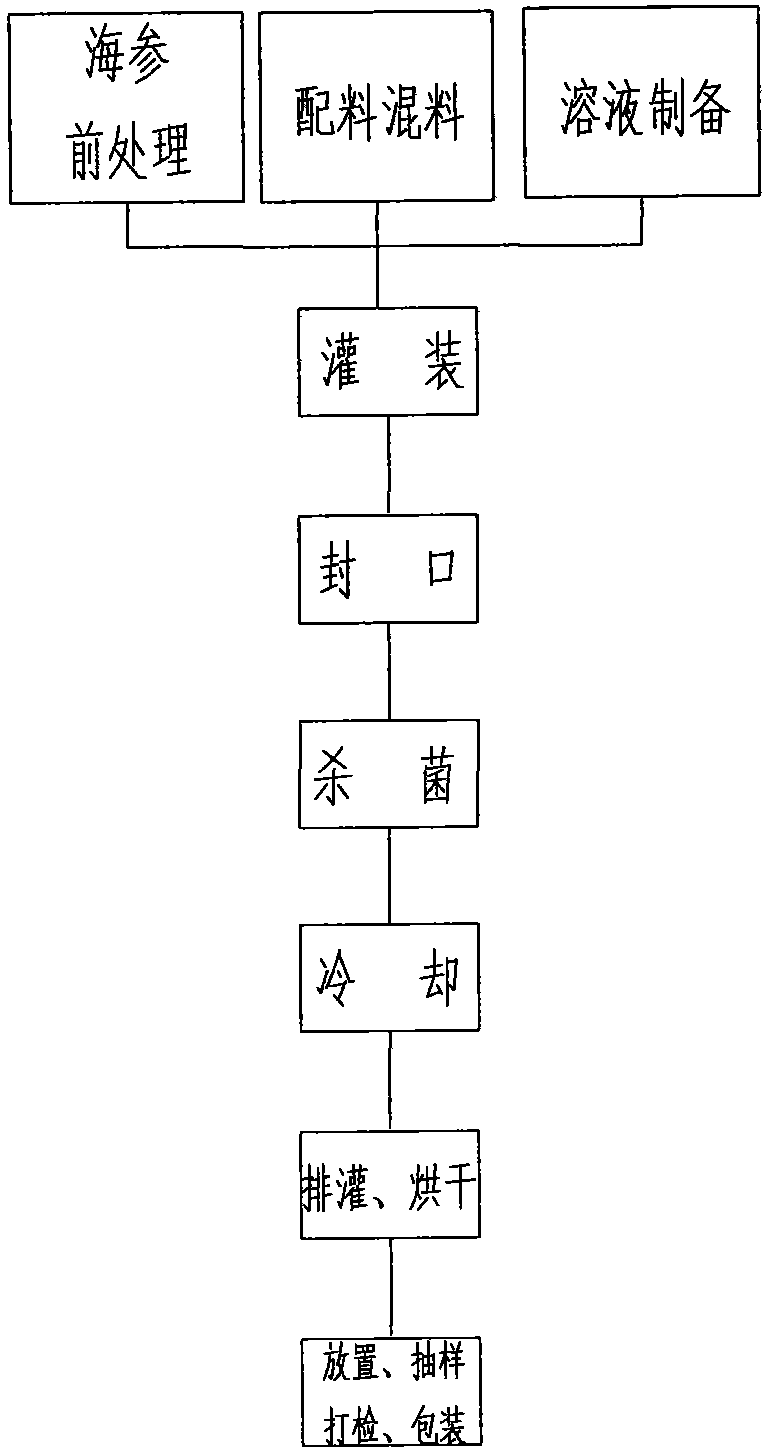

Method used

Image

Examples

Embodiment 1

[0052] 60 parts by weight of sea cucumbers are treated at a controlled temperature of 0° C. for 4 hours, adjusted to a pH of 4.5 with white vinegar and water, and then placed in sterile containers for storage.

[0053] 400 parts by weight of corn and 300 parts by weight of glutinous rice are washed and filtered with clear water and put into raw material container tanks of corn and glutinous rice;

[0054] Solution preparation, stir 1000 parts by weight of water and 0.5 parts by weight of β-carotene in the liquid storage tank, control the temperature at 80°C, so that β-carotene dissolves evenly in water; put it into filling machine.

[0055] Cleaning of empty cans. Empty tinplate cans must be cleaned and disinfected with hot water before use, and unqualified cans with bruises, flanging damage and defects should be removed.

[0056] Filling, put the processed sea cucumbers into empty tinplate cans, then fill the mixed granules in the granule filling machine into the tinplate ca...

Embodiment 2

[0064] 45 parts by weight of light-dried sea cucumbers were treated at a controlled temperature of 4° C. for 2 hours, adjusted to a pH of 5.5 with pure white vinegar and water, and then placed in sterile containers for storage.

[0065] The corn of 300 parts by weight, the glutinous rice of 250 parts by weight, the wheat kernel of 150 parts by weight, the sorghum of 100 parts by weight are washed and filtered with clear water and then divided into the raw material container tanks of corn, glutinous rice, wheat kernel and sorghum; The batching tank stirs and mixes evenly, and puts it into the granule filling machine.

[0066] Solution preparation, 1000 parts by weight of water and 0.2 parts by weight of β-carotene are stirred in the liquid storage tank, and the temperature is controlled at 90°C to make β-carotene dissolve evenly in the water; after fine filtration with a high-temperature resistant PP filter element, put it into filling machine.

[0067] Empty cans are cleaned,...

Embodiment 3

[0076] 15 parts by weight of light-dried sea cucumbers are treated at a controlled temperature of 3° C. for 2.5 hours, adjusted to a pH of 5.0 with white vinegar and water, and then placed in sterile containers for storage.

[0077] 200 parts by weight of corn; 300 parts of glutinous rice; 80 parts of wheat kernels; 80 parts of sorghum; 60 parts of soybeans; 50 parts of oats; 30 parts by weight of millet are washed and filtered with clear water and packed into various raw material container tanks; then, pumped into a batching tank for stirring, mixed evenly, and loaded into a particle filling machine.

[0078] For solution preparation, 1000 parts by weight of water is controlled at a temperature of 85° C., finely filtered through a high-temperature-resistant PP filter element, and loaded into a filling machine.

[0079] Cleaning of empty cans, special soft cans must be cleaned and disinfected with hot water before use, and unqualified cans with bruises, flanging damage and def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com