Method for producing mixed sugarcane tip feed with long quality guarantee period

A technology of mixed feed and production method, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of difficulty for farmers to complete it alone, high processing technology requirements, and lack of popularization, so as to reduce breeding costs, long storage time, The effect of rapid promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

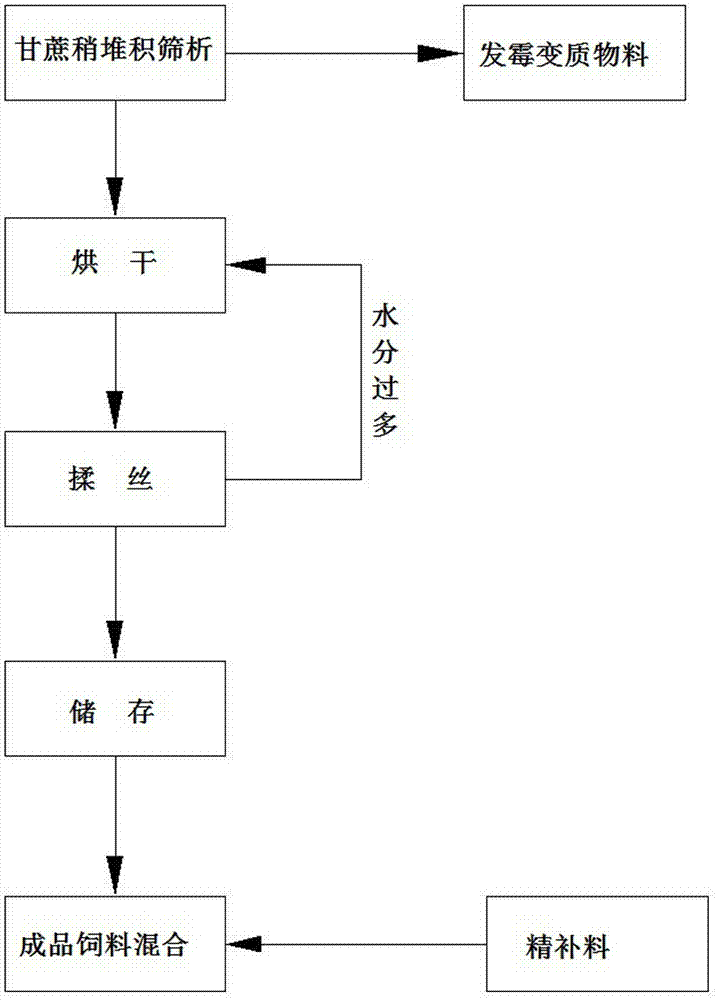

[0022] Such as figure 1 Shown is a long shelf-life sugarcane slightly mixed feed production method, including sugarcane slightly piled up and screened, dried, shredded, stored, and finished feed mixed. The specific steps are as follows:

[0023] Slight accumulation and screening of sugarcane: Slightly arrange and sort the sugarcane collected from the sugarcane field, slightly remove the moldy and deteriorated sugarcane, and then stack the sorted sugarcane at room temperature for 0.5 days to balance the water in the sugarcane;

[0024] Drying: Send the sugarcane after moisture equalization to the dryer for drying, the drying time is 1.5 minutes, and the drying temperature is 130°C;

[0025] Kneading: Send the dried sugarcane to the kneading machine for kneading;

[0026] Storage: store sugarcane shreds in a dry place at normal temperature and pressure;

[0027] Finished feed mixing: mix sugarcane shreds and energy feed at a ratio of 1:1 to form a finished mixed feed...

Embodiment 2

[0030] Such as figure 1 Shown is a long shelf-life sugarcane slightly mixed feed production method, including sugarcane slightly piled up and screened, dried, shredded, stored, and finished feed mixed. The specific steps are as follows:

[0031] Slight accumulation and screening of sugarcane: Sorting and sorting the sugarcane collected from the sugarcane field, removing impurities from the moldy and deteriorated sugarcane, and stacking the sorted sugarcane at room temperature for 1 day to balance the water in the sugarcane;

[0032] Drying: Send the sugarcane after water balance to the dryer for a while for drying, the drying time is 5 minutes, and the drying temperature is 140°C;

[0033] Kneading: Send the dried sugarcane to the kneading machine for kneading;

[0034] Storage: store sugarcane shreds in a dry place at normal temperature and pressure;

[0035] Finished feed mixing: mix sugarcane shreds and energy feed at a ratio of 2:1 to form a finished mixed feed...

Embodiment 3

[0038] Such as figure 1 Shown is a long shelf-life sugarcane slightly mixed feed production method, including sugarcane slightly piled up and screened, dried, shredded, stored, and finished feed mixed. The specific steps are as follows:

[0039] Slight accumulation and screening of sugarcane: Sorting and sorting the sugarcane collected from the sugarcane field, removing impurities from the moldy and deteriorating sugarcane, and stacking the sorted sugarcane at room temperature for 3 days to balance the water in the sugarcane;

[0040] Drying: Send the sugarcane after moisture equalization to the dryer for drying, the drying time is 15 minutes, and the drying temperature is 150°C;

[0041] Kneading: Send the dried sugarcane to the kneading machine for kneading;

[0042] Storage: store sugarcane shreds in a dry place at normal temperature and pressure;

[0043] Finished feed mixing: mix sugarcane shreds and energy feed at a ratio of 3:1 to form a finished mixed feed. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com