Method for improving drought resistance of lawn plants through dried sludge

A technology of air-drying sludge and drought resistance, which is applied in the fields of botanical equipment and methods, horticultural methods, sewage/sludge fertilizers, etc., can solve the problems of reducing the cost of sludge reuse and shortening the time of sludge reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

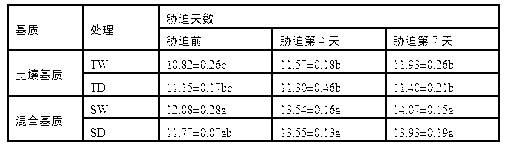

Image

Examples

Embodiment 1

[0078] (1) Tall fescue seeds with full and uniform grains were selected as test materials; the collected soil was placed on plastic cloth, flattened and crushed, passed through a 2 mm sieve, placed at the vent for 2 days, and air-dried under natural conditions. The organic matter content is 4.68%, the total nitrogen content is 0.21%, the available phosphorus content is 22.03 mg / kg, the total potassium content is 324.3 mg / kg, the pH value is 7.44, and the saturated moisture content is 0.58 ml / g; the sludge for testing is collected from Tianjin Jizhuangzi Sewage Treatment Plant. The collected sludge was crushed through a 2mm sieve, spread flat on plastic cloth and placed at the vent for 2 days, and air-dried under natural conditions. The organic matter content of the sludge was 18.21%, the total nitrogen content was 1.41%, and the available phosphorus content was 187 mg / kg. The total potassium content is 652.9 mg / kg, and the water content is 2.13%;

[0079] (2) Select a petri di...

Embodiment 2

[0084] (1) Select tall fescue seeds with full and uniform grains as the test material; collect the soil and place it on plastic cloth, flatten and crush it, pass through a 2mm sieve, and place it at the vent for 3 days, air-dry under natural conditions, and the soil organic matter content 4.68%, total nitrogen content 0.21%, available phosphorus 22.03 mg / kg, total potassium content 324.3 mg / kg, pH 7.44, saturated water content 0.58 ml / g; the sludge for test was collected from Tianjin Jizhuangzi Sewage Treatment Plant, collected The final sludge was crushed through a 2mm sieve, spread flat on plastic cloth and placed at the vent for 2 days, and air-dried under natural conditions. The organic matter content of the sludge was 18.21%, the total nitrogen content was 1.41%, the available phosphorus content was 187mg / kg, and the total potassium The content is 652.9mg / kg, and the water content is 2.13%;

[0085] (2) Select a petri dish with a diameter of 9.5cm and a height of 1.5cm as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com