Automatic matching method for high-precision complex product assembling materials

A complex product and material technology, which is applied in the field of automatic assembly of high-precision and complex product assembly materials, can solve the problems of unreasonable matching sequence, many documents to be filled out, and low degree of automation, and achieve the effects of convenient query, efficient operation, and automatic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

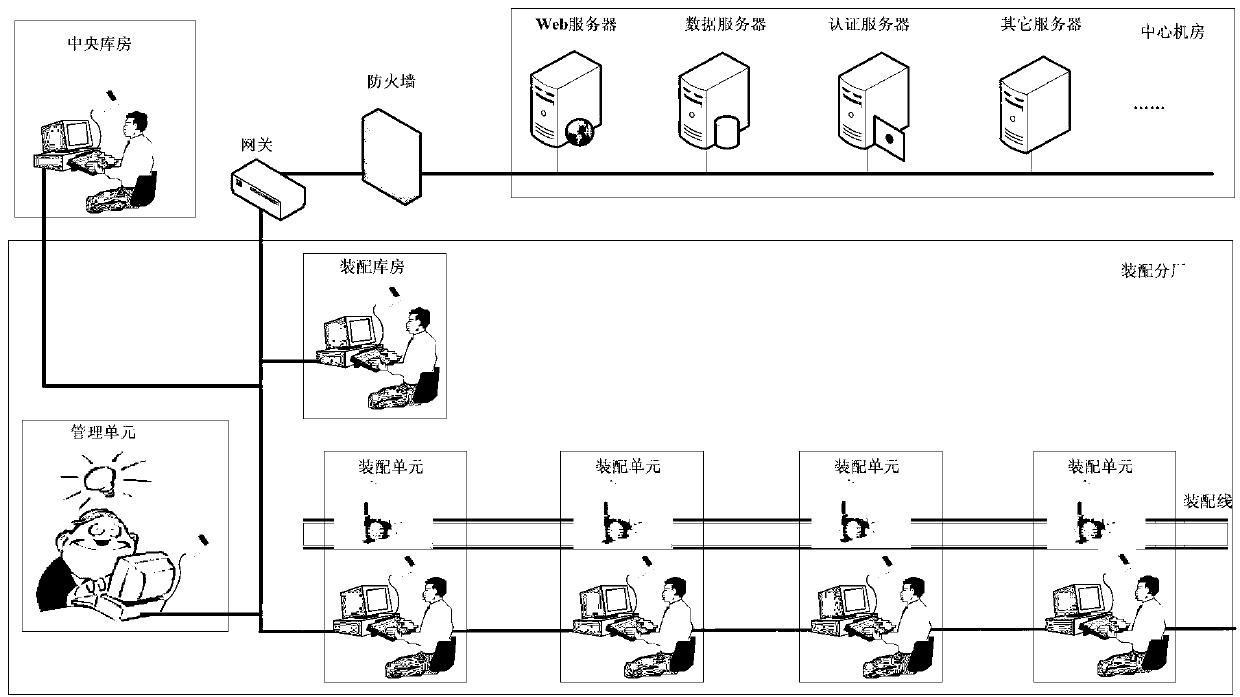

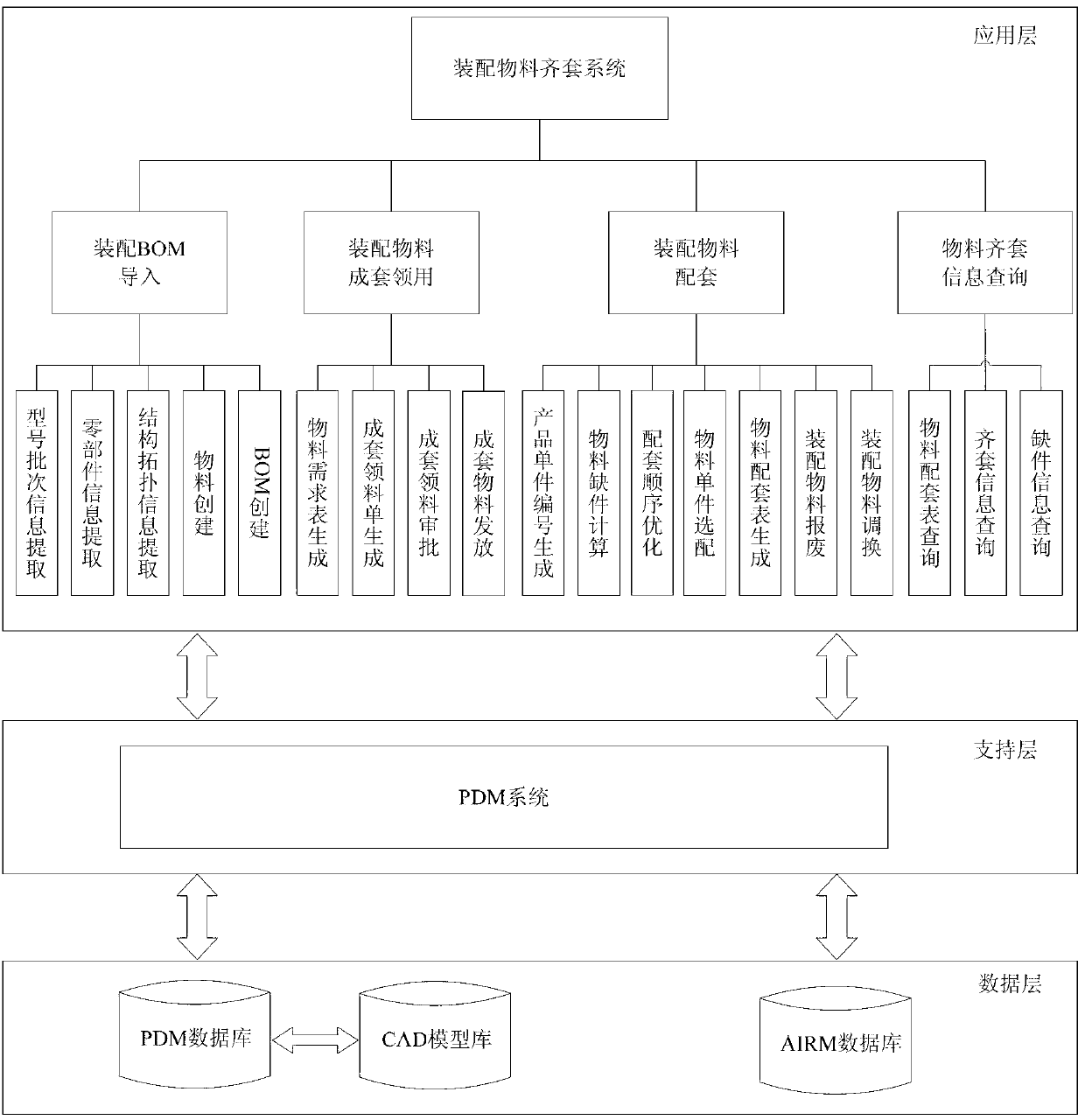

[0041] Such as Figure 1-21 shown.

[0042] A method for automatically aligning high-precision and complex product assembly materials, which includes the following steps:

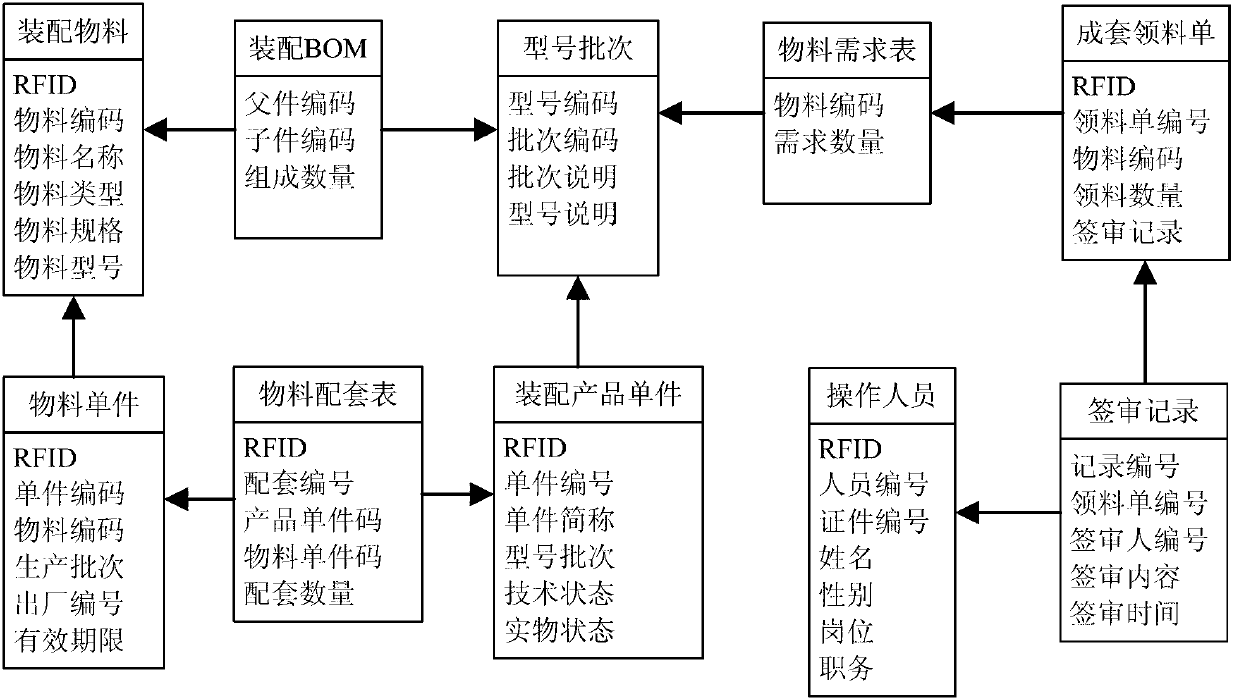

[0043]First, according to the model batch information of the product to be assembled, the process designer retrieves the assembly CAD model from the PDM system. Call CAD secondary development interface program, apply recursive algorithm to traverse unstructured CAD model files, read structural topology information of CAD files and basic attribute information of components, parts, and standard parts in batches, and automatically create structured assembly materials by the program and assembly BOM, and stored in AIRM_DB, the complete set of assembly material database.

[0044] Second, generate a new product unit number and a new material matching number for each product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com