Driving control system for gas extruding suspension device and method thereof

A levitation device, drive control technology, applied in the direction of electric controllers, controllers with specific characteristics, etc., can solve the problems of capacitive reactance drop, capacitance change, and influence on the output of drive power, so as to improve the levitation accuracy, reduce friction, The effect of improving suspension reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

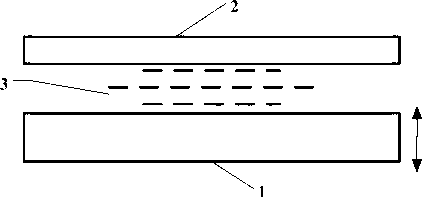

[0025] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Please refer to Figure 1 to Figure 6 As shown, the drive control system of the gas extrusion levitation device of the present invention mainly includes a digital controller module, a signal generator module, a controllable gain amplifier module, a piezoelectric ceramic drive power module and a signal processing module. The signal output terminal of the signal generator module is connected to the signal input port of the controllable gain amplifier module for primary amplification of the sinusoidal signal generated by the signal generator module; the output terminal of the controllable gain amplifier module is connected to the input terminal of the piezoelectric ceramic drive power module connected to the primary amplified sinusoidal signal for power amplification; the output port of the piezoelectric ceramic drive power module is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com