Rail clearance sensor for magnetic suspension train

A maglev train and gap sensor technology, applied in the field of rail gap sensors, can solve the problems of high failure rate, achieve high reliability, long service life, and improve suspension reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

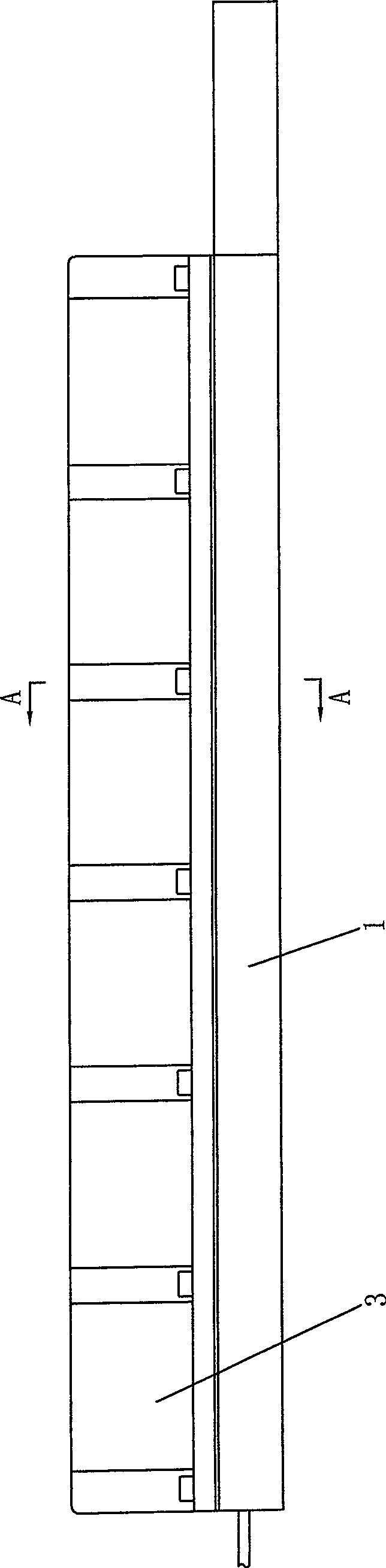

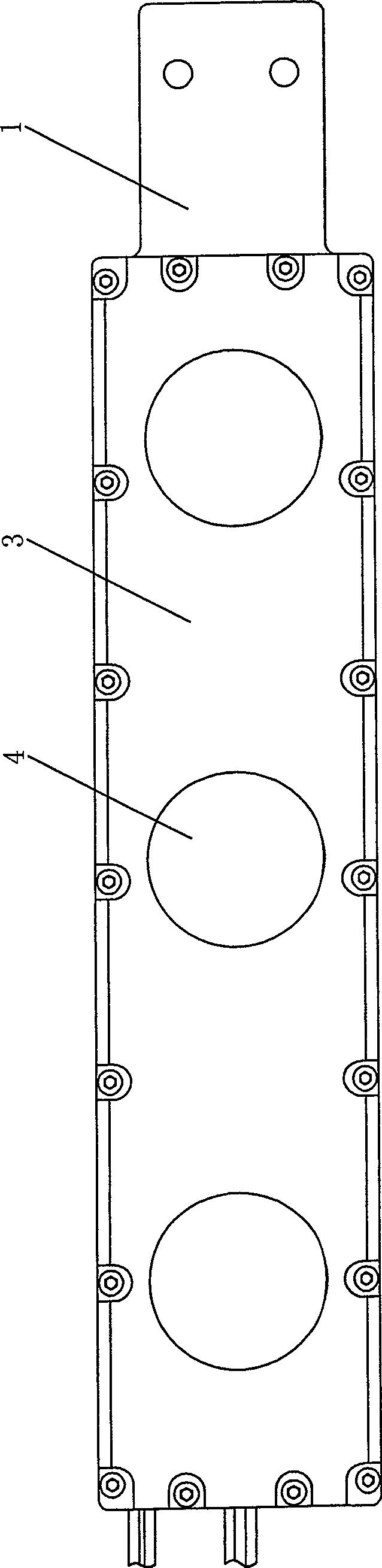

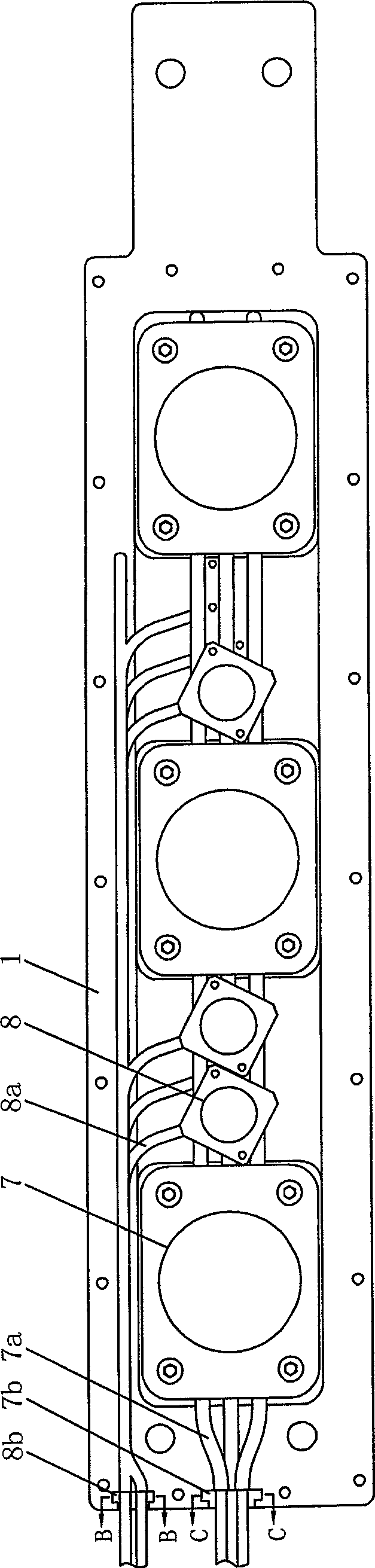

[0020] Figure 1~3 Shown, a kind of specific embodiment of the present invention is:

[0021] A track gap sensor for a maglev train, comprising a gap probe 7, a gap probe lead 7a, an acceleration sensor 8, an acceleration sensor lead 8a, characterized in that: the gap probe 7 and the acceleration sensor 8 are three, three The gap probe 7 and the three acceleration sensors 8 are installed on the mounting base 1 one by one along the strip-shaped groove of the strip-shaped mounting base 1, and the sealing cover 3 covering the gap probe 7 and the acceleration sensor 8 is fixed on the mounting base 1 .

[0022] figure 2 It is shown that the position where the upper part of the sealing cover 3 faces the gap probe 7 has a probe hole adapted to the size of the gap probe 7, and the opening is equipped with a probe cover 4 made of an epoxy plate of the same size, and the sealing cover 3 and the probe cover 4 are bonded with an insulating adhesive.

[0023] The mounting seat 1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com