Liquid crystal display panel, manufacturing method thereof and display device

A technology of liquid crystal panels and manufacturing methods, applied in optics, instruments, nonlinear optics, etc., can solve the problems of high driving voltage and low contrast, achieve the effects of reducing driving voltage, increasing contrast, and improving electro-optic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

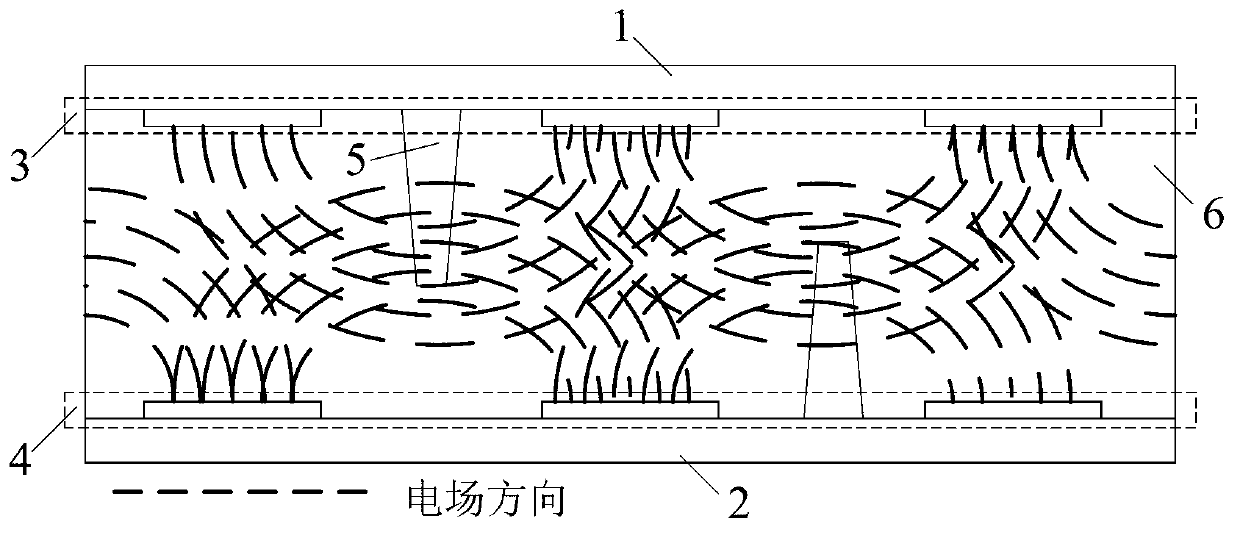

[0047] The embodiment of the present invention aims at the problem that the trans PDLC film prepared by using negative liquid crystal has the disadvantages of high driving voltage and low contrast in the prior art, and provides a liquid crystal panel, a manufacturing method thereof, and a display device, which can reduce the trans PDLC film. The driving voltage of the PDLC film increases the contrast of the trans PDLC film.

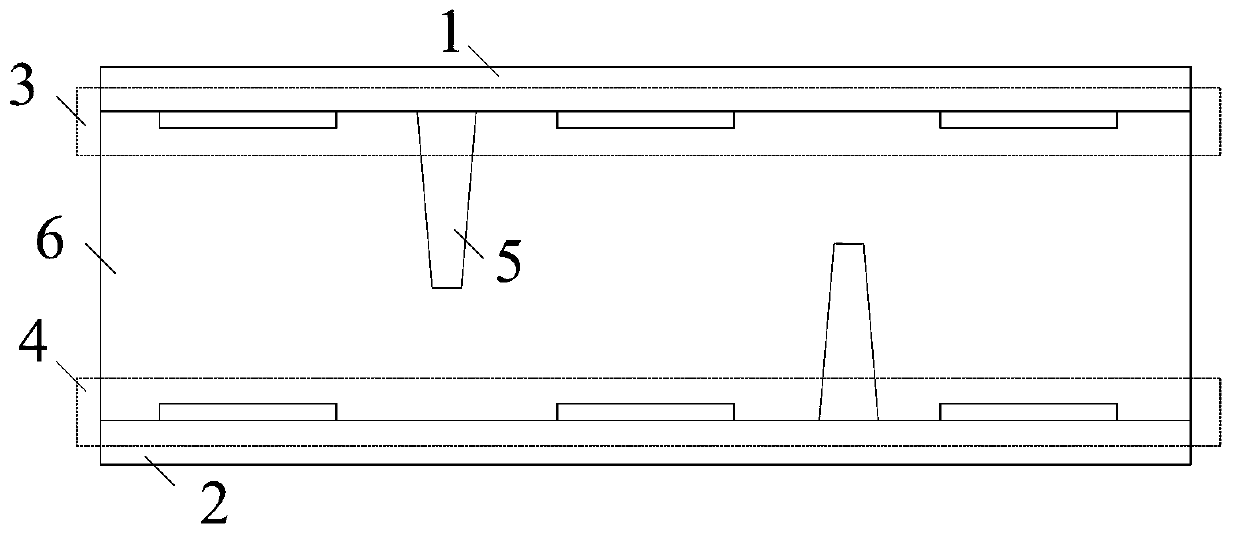

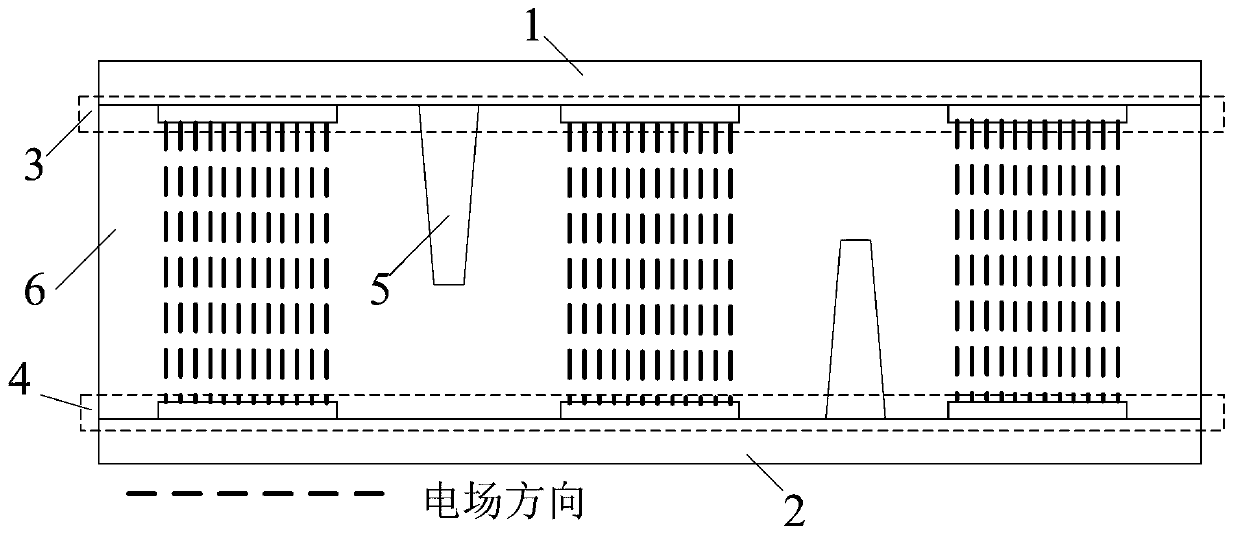

[0048] An embodiment of the present invention provides a liquid crystal panel, including a first substrate and a second substrate oppositely arranged, and a PDLC layer arranged between the first substrate and the second substrate, wherein the PDLC layer is composed of positive liquid crystal and The polymer matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com